Feeding mechanism of neodymium iron boron magnetic field forming press

A magnetic field forming and feeding mechanism technology, which is applied in the direction of magnetic materials, mechanical equipment, magnetic objects, etc., can solve the problems of high dust-proof requirements and affect production efficiency, and achieve low dust-proof requirements, fast driving speed, and high reliability in use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further explained in conjunction with the accompanying drawings.

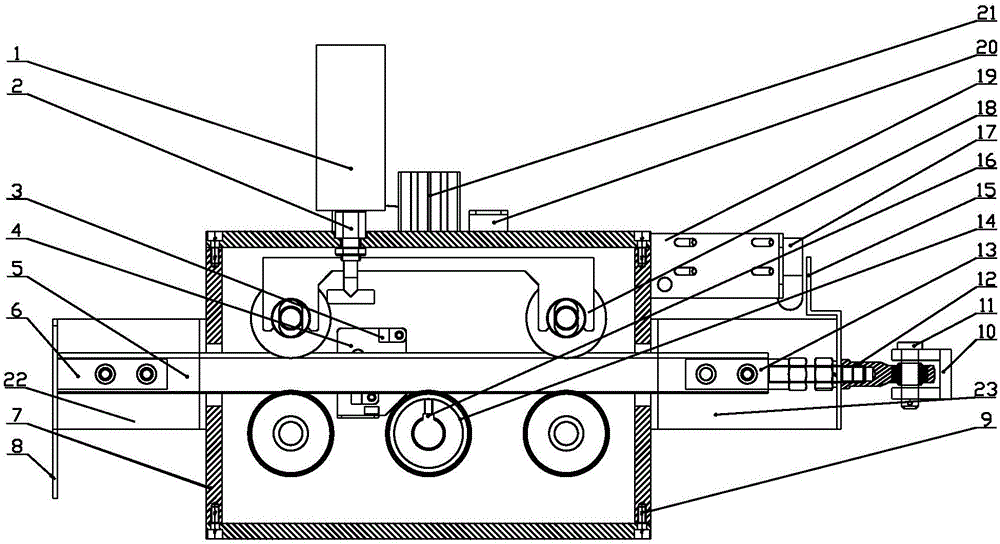

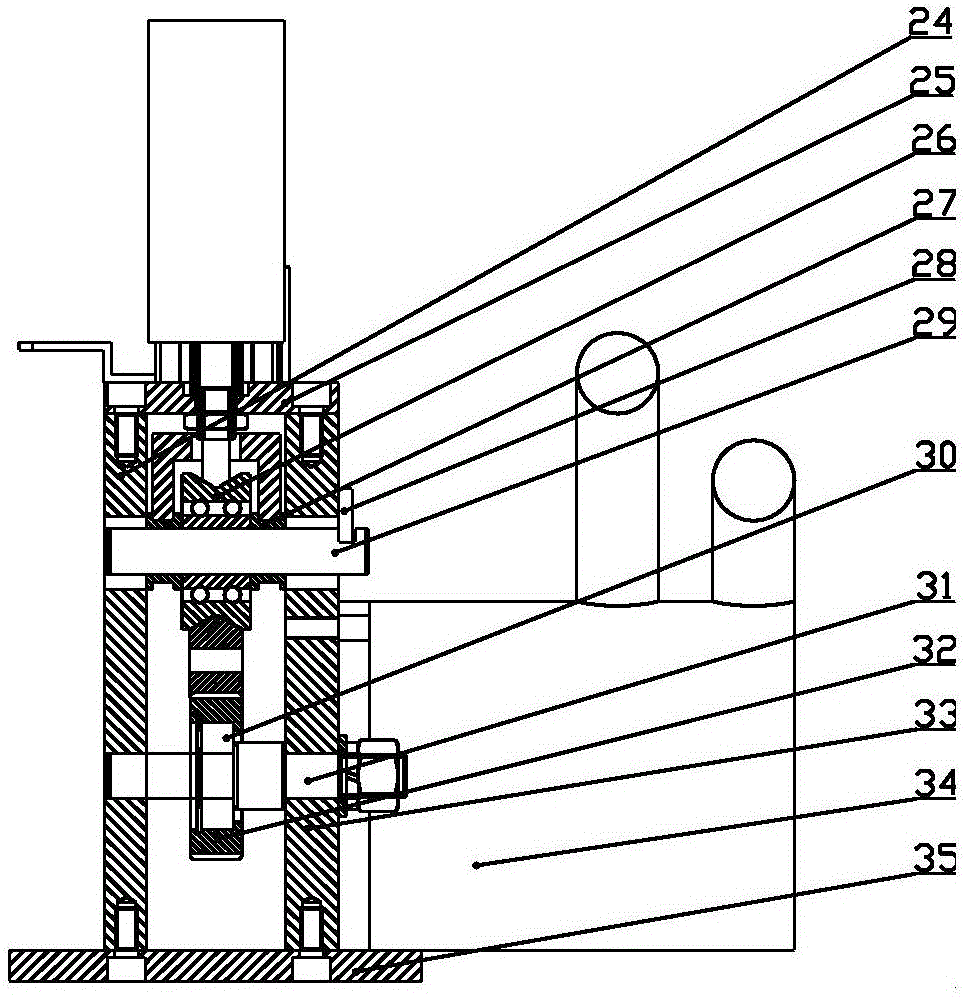

[0016] see Figure 1-2 , a feeding mechanism of an NdFeB magnetic field forming press, comprising a gear box and a rack 5 pierced through the gear box, the gear box consists of a bottom plate 35, a front side plate 9, a rear side plate 7, a left side plate 24, and a right side plate The plate 33 and the top plate 25 are connected by screws to form a rectangular box. The front side plate 9 and the rear side plate 7 are provided with through holes for the rack 5 to pass through. Each side plate of the gear box can be disassembled, which is convenient for disassembly and maintenance. .

[0017] The gear box is provided with a driving gear 14 driven by a servo motor 34. The servo motor 34 is installed on the right side plate 33 of the gear box body. The drive shaft of the servo motor 34 extends into the gear box and is connected with the driving gear 14 through a flat key 16. . In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com