Blank stacking machine

A stacking machine and stacking technology, applied in the field of stacking brick equipment, can solve the problems of high manufacturing precision of column structures, increase of enterprise costs, waste of manpower and material resources, etc., to achieve simple structure, save enterprise costs, and more stable translation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

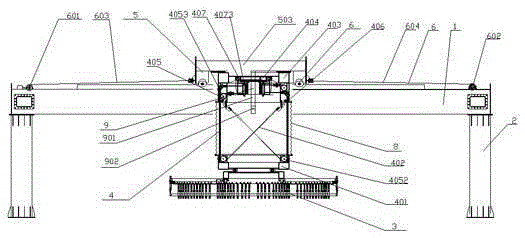

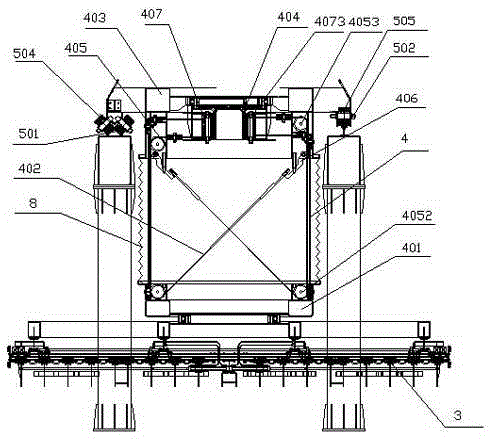

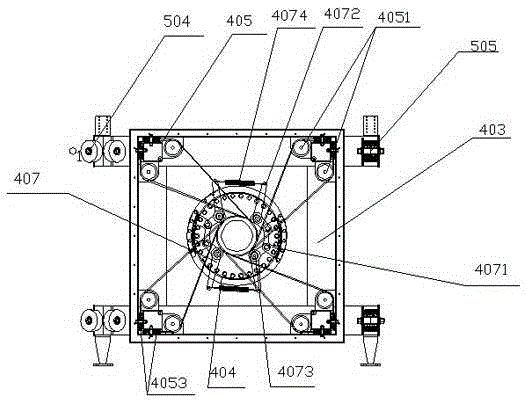

[0023] As shown in the figure, the present invention is a stacking machine, including a stacking device 3, two parallel beams 1 and a column 2 supporting the beams 1, and a control stacking device 3 is installed between the two beams 1 The lifting device 4 is provided with a translation device 5 for controlling the translation of the lifting device 4 on the beam 1, and the translation device 5 includes a traveling carriage 503 and a V-shaped track 501 and an I-shaped track 502 respectively arranged on the beam 1, The walking trolley 503 moves on the V-shaped track 501 and the I-shaped track 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com