A CNC lathe

A technology of CNC lathes and lathes, applied in the field of CNC lathes, can solve problems such as bolt loosening, nut pair translation obstruction, dirt, etc., and achieve the effects of avoiding blockage, smooth translation, and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

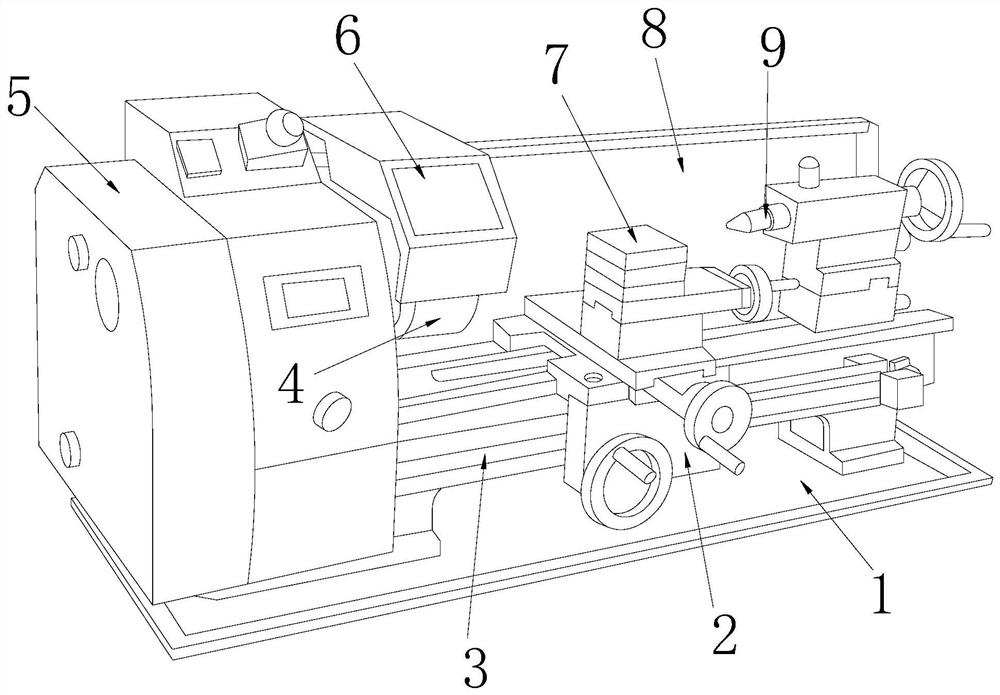

[0043] see figure 1 , the present invention provides a technical solution for a numerically controlled lathe: please refer to Figure 1-3 , the present invention provides a technical solution for a CNC lathe: its structure includes a base 1, a moving assembly 2, a screw assembly 3, a chuck 4, a lathe body 5, a dust cover 6, a lathe tool rest 7, a guard plate 8, Tailstock jacking mechanism 9, described base 1 is provided with lathe body 5, and described lathe body 5 is fixed with guard plate 8, and described lathe body 5 is equipped with chuck 4, and above described chuck 4 is provided with dust-proof Cover 6, one side of the chuck 4 is provided with a tailstock jacking mechanism 9, and the tailstock jacking mechanism 9 is movably connected with the lathe body 5, and the lathe body 5 is provided with a screw assembly 3, and the wire The rod assembly 3 is connected with a mobile assembly 2, and the movable assembly 2 is fixed with a liftable lathe tool rest 7;

[0044] see ...

Embodiment 2

[0052] see figure 1 , the present invention provides a technical solution for a CNC lathe: its structure includes a base 1, a moving assembly 2, a screw assembly 3, a chuck 4, a lathe body 5, a dust cover 6, a lathe tool rest 7, a guard plate 8, Tailstock jacking mechanism 9, described base 1 is provided with lathe body 5, and described lathe body 5 is fixed with guard plate 8, and described lathe body 5 is equipped with chuck 4, and above described chuck 4 is provided with dust-proof Cover 6, one side of the chuck 4 is provided with a tailstock jacking mechanism 9, and the tailstock jacking mechanism 9 is movably connected with the lathe body 5, and the lathe body 5 is provided with a screw assembly 3, and the wire The rod assembly 3 is connected with a mobile assembly 2, and the movable assembly 2 is fixed with a liftable lathe tool rest 7;

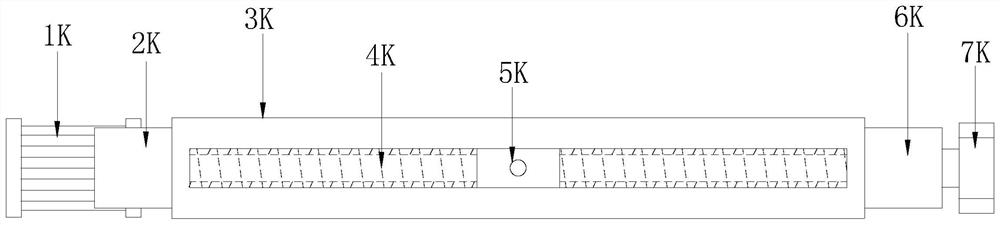

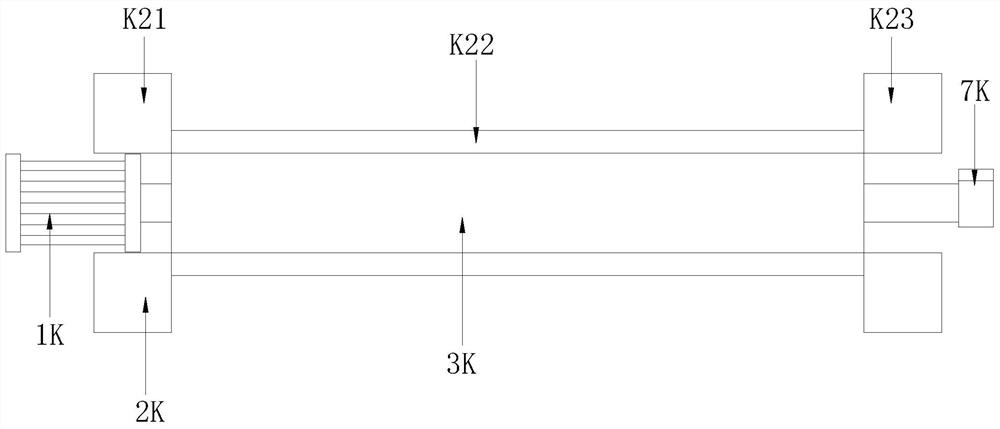

[0053] see figure 2 , Figure 4 , the screw assembly 3 includes a micro motor 1K, No. 1 dust-proof device 2K, dust-proof box 3K, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com