Preparation method of graphene film

A graphene film and film technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of graphene powder covering blind spots, dirt, uneven graphene coverage, etc. Improve laying effect, improve uniformity, lay uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

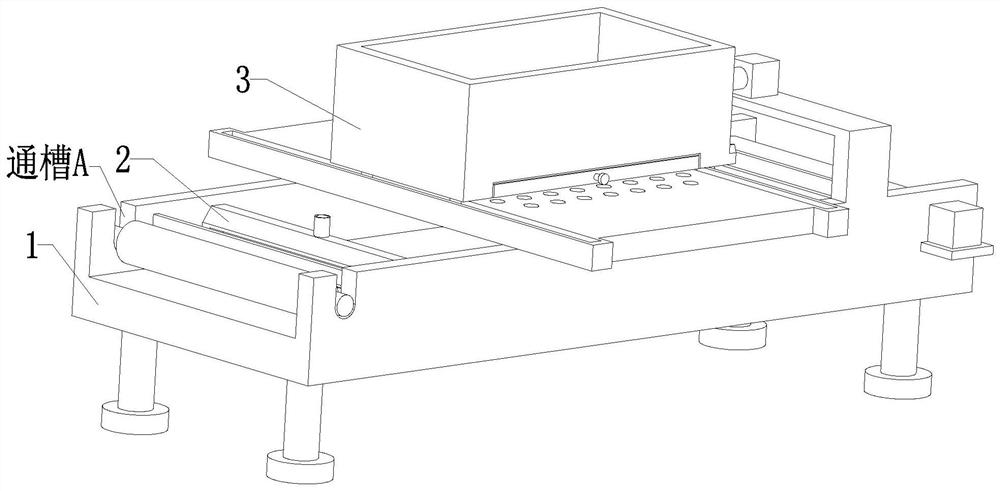

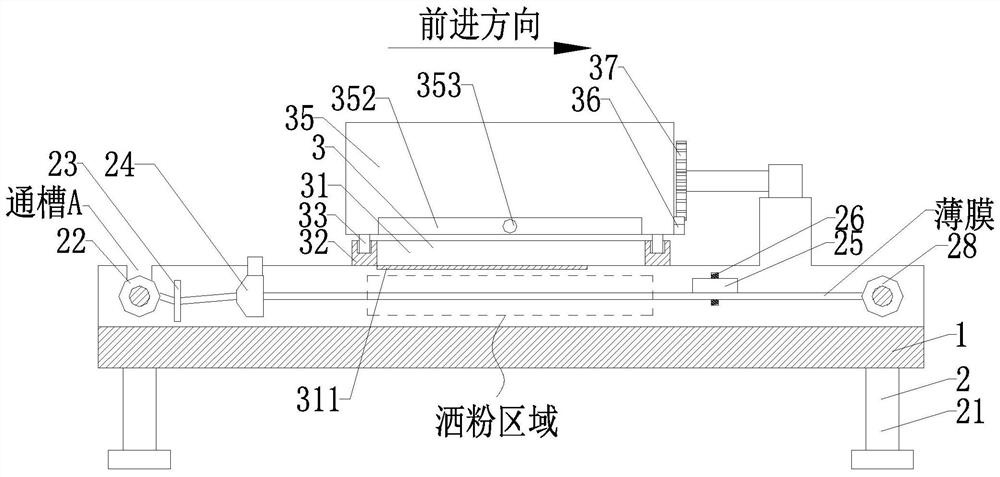

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

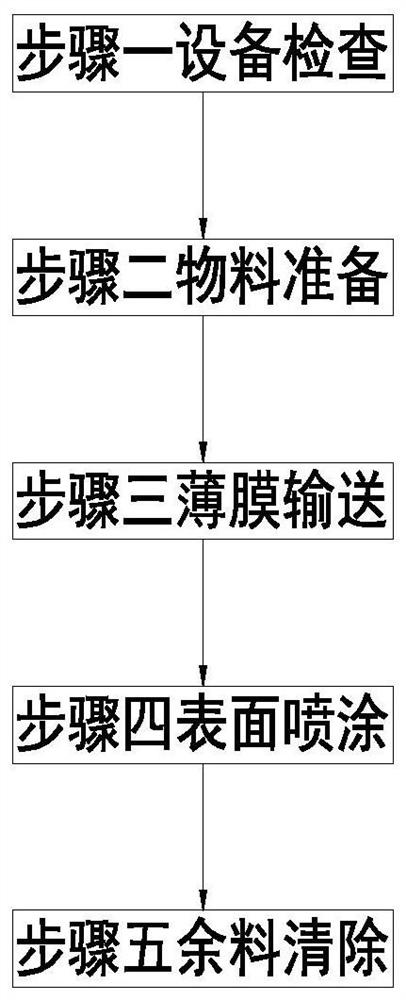

[0032] like Figure 1 to Figure 7 Shown, a kind of graphene film preparation method mainly comprises the following steps:

[0033] Step 1: Equipment inspection: before enabling the graphene film forming equipment for graphene film production, check the operation of the equipment;

[0034] Step 2: Material preparation: manually connect the winding column 28 and the docking plate 29 through the connecting pin 20, then manually place the charging column 22 with the transparent film inside the slot A, and then manually pass the transparent film through Tightening block 23, blowing block 24, and are connected together with winding column 28, then manually pour graphene powder into charging frame 35, thereby complete material preparation operation;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com