Steel wire retainer ring shaping mechanism

A steel wire retaining ring and steel wire technology, which is applied in the field of steel wire retaining ring shaping mechanism, can solve the problems of steel wire retaining ring deformation, product damage, and difficulty in precision control, and achieve the effect of neat and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

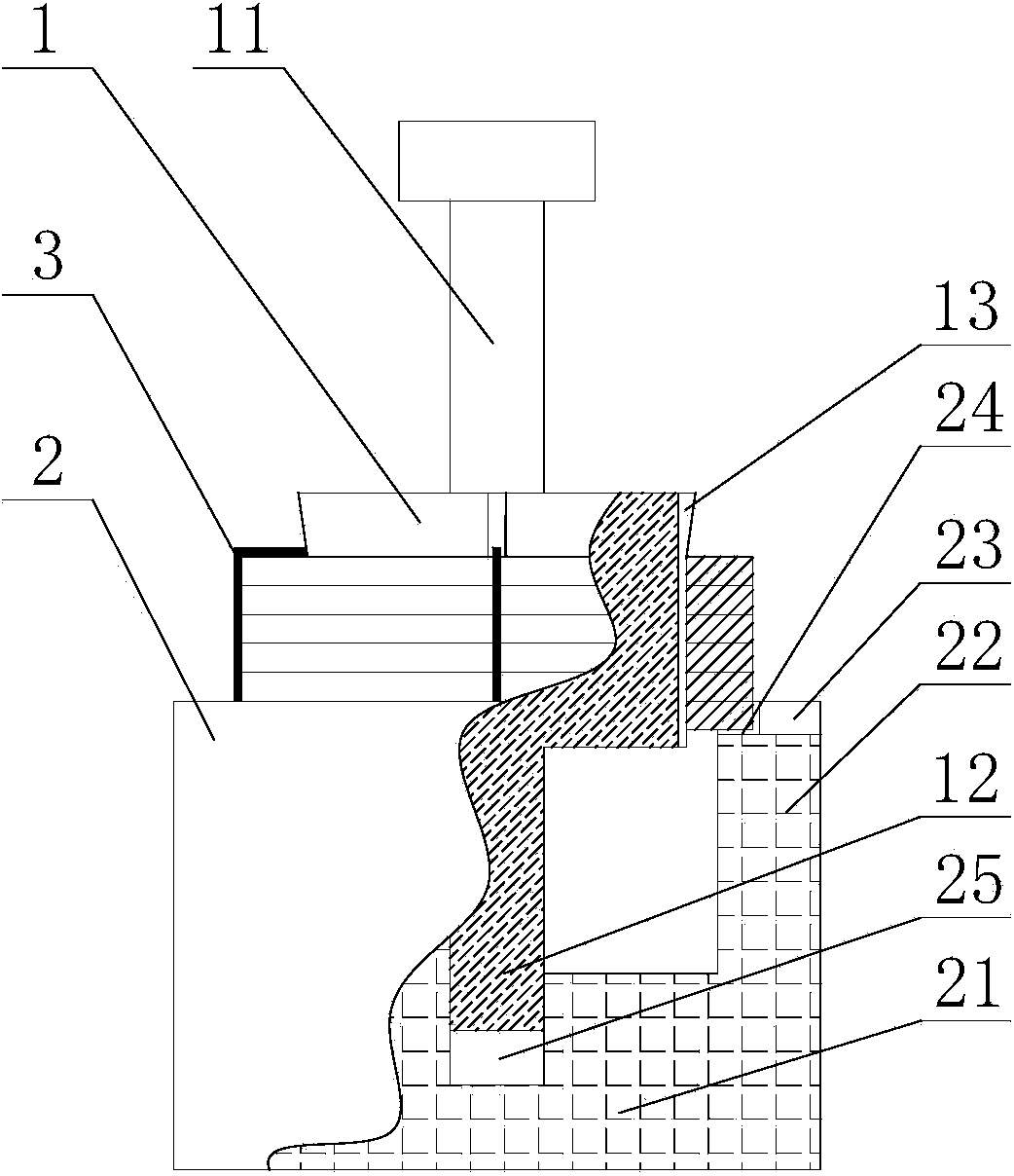

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a wire retaining ring shaping mechanism proposed by the present invention.

[0016] refer to figure 1 , a steel wire retaining ring shaping mechanism proposed by the present invention, comprising: a cylindrical core 1, a sleeve 2 and a fastening steel wire 3;

[0017] The middle part of the upper surface of the cylindrical core body 1 is provided with an upwardly protruding force bearing block 11, and its lower surface is provided with a downwardly protruding guide pillar 12. The outer diameter of the cylindrical core body 1 is A1, and the outer diameter of its upper part is A2. The inner diameter of the shaping retaining ring is D1, the outer diameter of the retaining ring is D2, A1<D1<A2, specifically, A2 is 1.05-1.1 times of A1, and the side wall of the cylindrical core 1 is provided with a shaft from the upper surface to the downward direction. A plurality of grooves 13 extending to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com