Variable-speed printing control algorithm of CIJ ink-jet printing machine

A technology of printing control and inkjet printer, which is applied in printing and other directions, can solve the problems of ink dot interference, ink dot flying, and printing uniformity reduction, so as to reduce interference, improve neatness and aesthetics, and reduce scattered ink. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

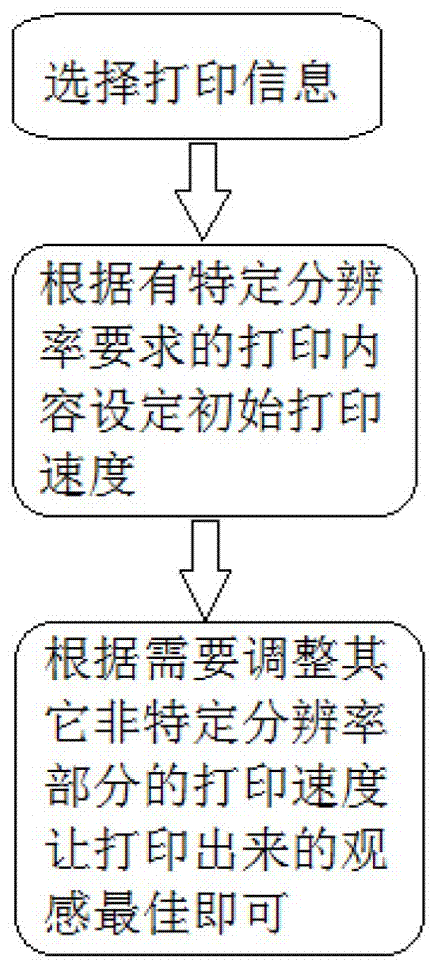

[0031] Such as figure 1 As shown, the variable speed printing control algorithm of the CIJ inkjet printer disclosed by the present invention includes:

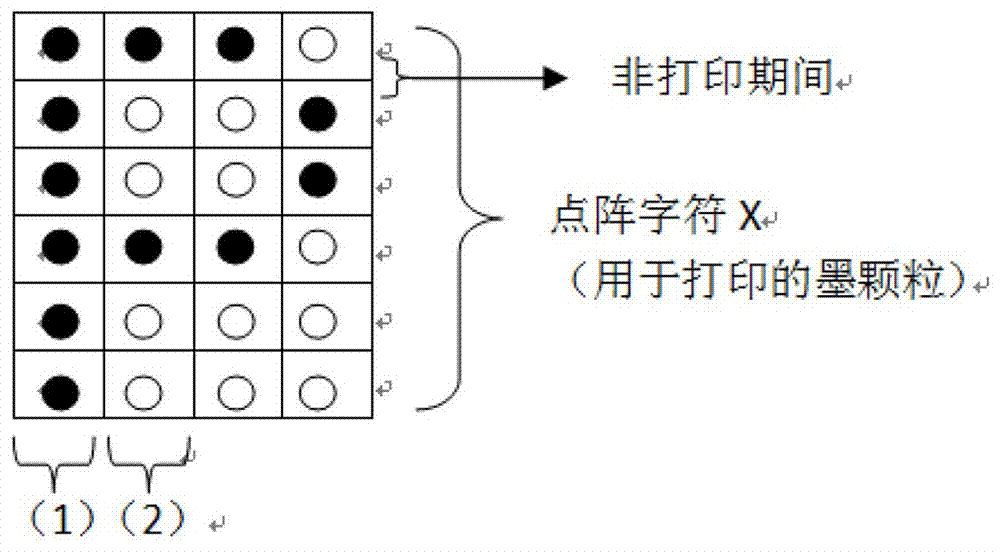

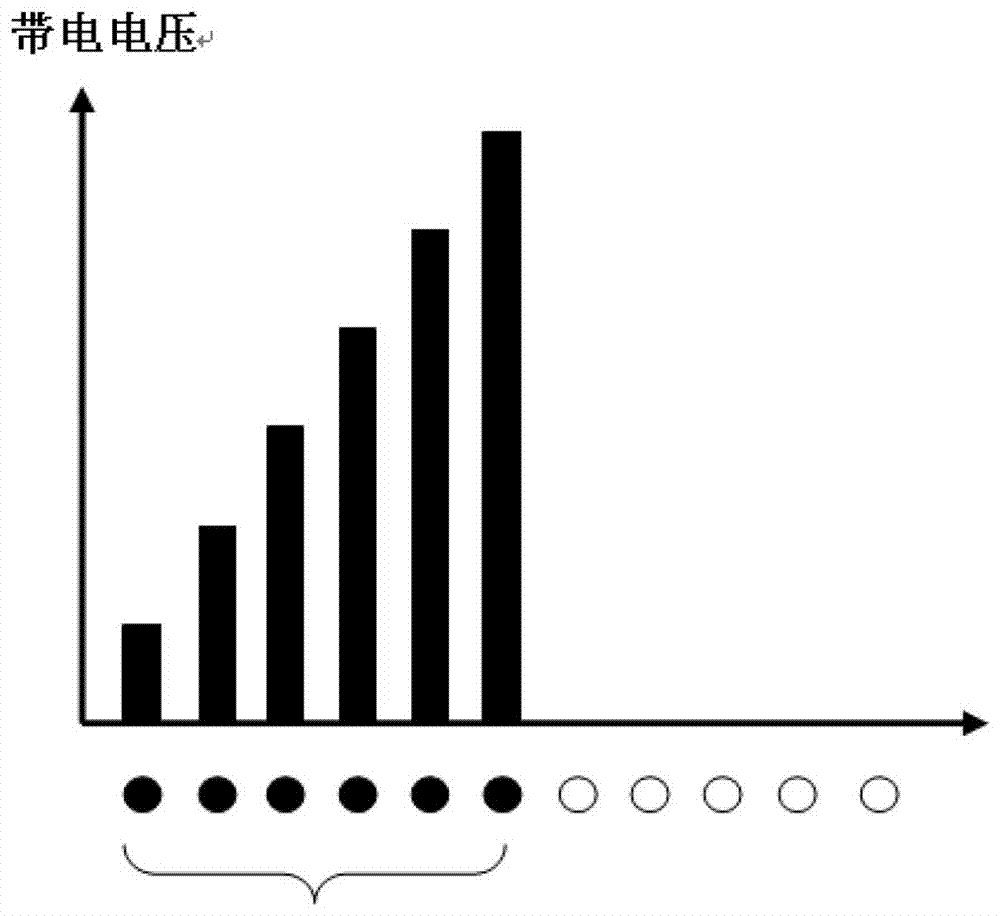

[0032] For a piece of printing data, set its initial printing speed first, and the initial printing speed can make the printing data clear; can be obtained by directly observing the printed content), then the printing data is divided into the modified speed area and the speed unchanged area. Increase the spacing between printed ink dots by interpolating more non-printed ink drops than in the constant-velocity zone to reduce the printing speed in the velocity-modified zone.

[0033] The process of reducing the printing speed of the modified speed area is specifically:

[0034] Step 1: For the speed modification area, first set the initial printing speed of this area according to the printing content with specific resolution requirements. The initial printing speed is determined according to the parameter scale, and the value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com