Continuous fiber prepreg tape inner layer wall reinforced corrugated pipe and production equipment thereof

A continuous fiber and production equipment technology, which is applied in the field of continuous fiber prepreg belt inner wall reinforced bellows and its production equipment, can solve the problems of reduced diameter error, poor interface sealing, shortened pipeline, etc., to reduce the linear expansion coefficient , avoid interface leakage, and avoid the effect of external collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

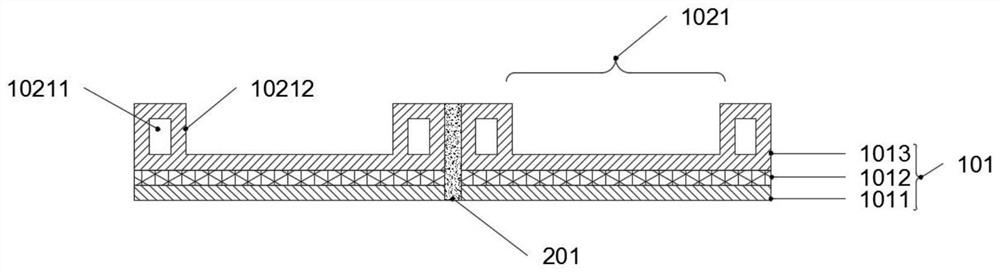

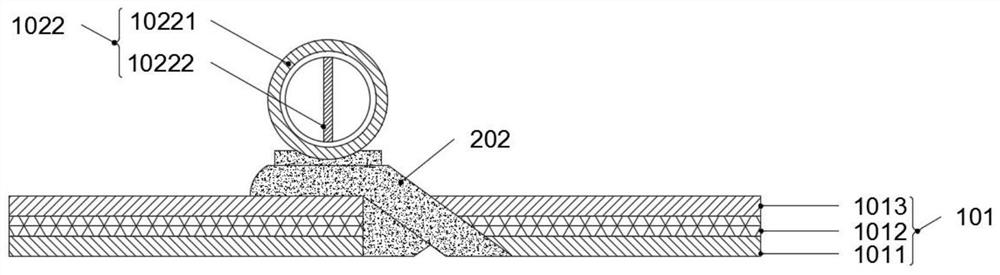

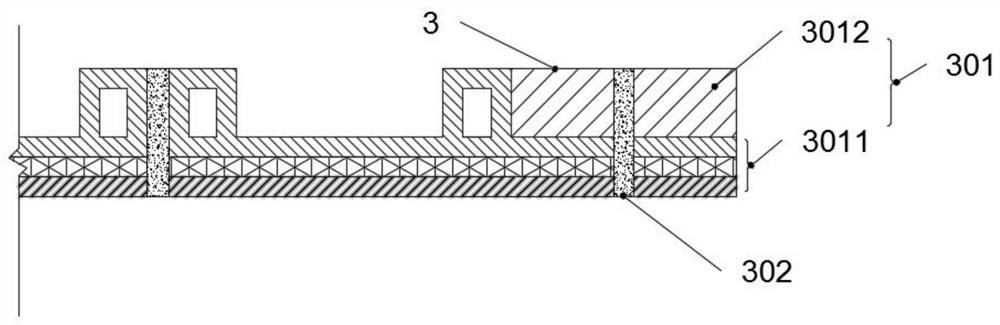

[0029] Example: such as Figure 1-3 As shown, a continuous fiber prepreg inner wall reinforced corrugated pipe of the present invention and its production equipment include a composite pipe body 1, a pipe body fusion joint 2 and a pipe end butt joint 3, and the composite pipe body 1 is preimpregnated by continuous fibers A reinforced composite inner layer wall 101 and a structurally stiffened bellows 102 are formed. The composite inner layer wall 101 is composed of an anti-corrosion plastic inner layer 1011, a continuous fiber prepreg tape reinforcement layer 1012 and an excessive plastic layer 1013. The structure The corrugated pipe 102 is composed of a concave structural plastic pipe 1021 and a circular structural plastic pipe 1022. The concave structural plastic pipe 1021 is composed of a built-in hollow body 10211 and a plastic support 10212. The circular structural plastic pipe 1022 is composed of a plastic circular Consists of tube 10221 and reinforced inner rib 10222; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com