Anti-drop power plug and socket assembly for material bending machine

A power plug and anti-dropping technology, which is applied in the field of bending machine, can solve the problems of power socket and power plug falling off, work interruption, shortening the service life of bending machine, etc., so as to ensure normal operation and increase plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

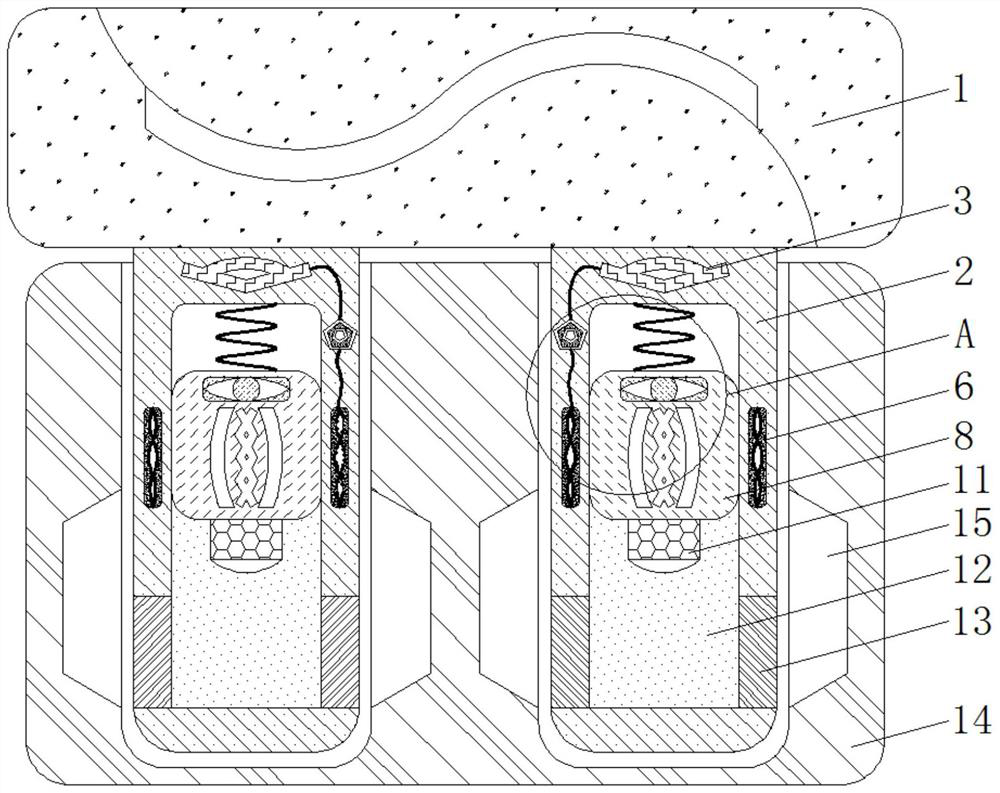

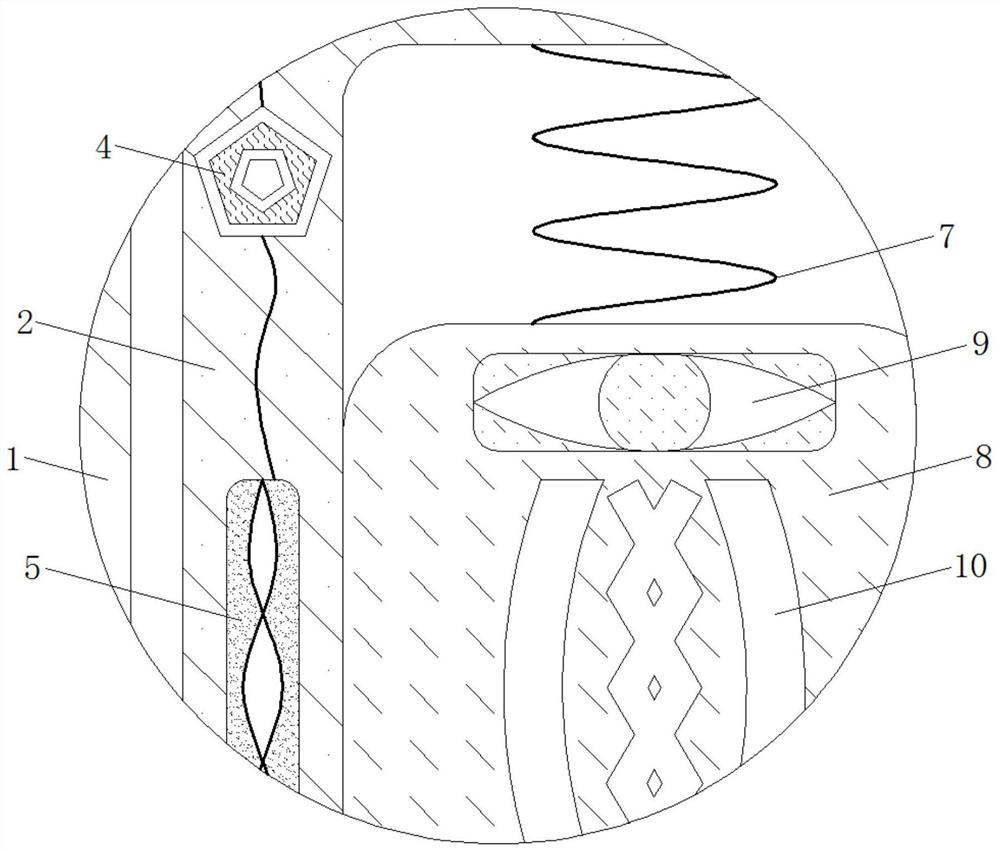

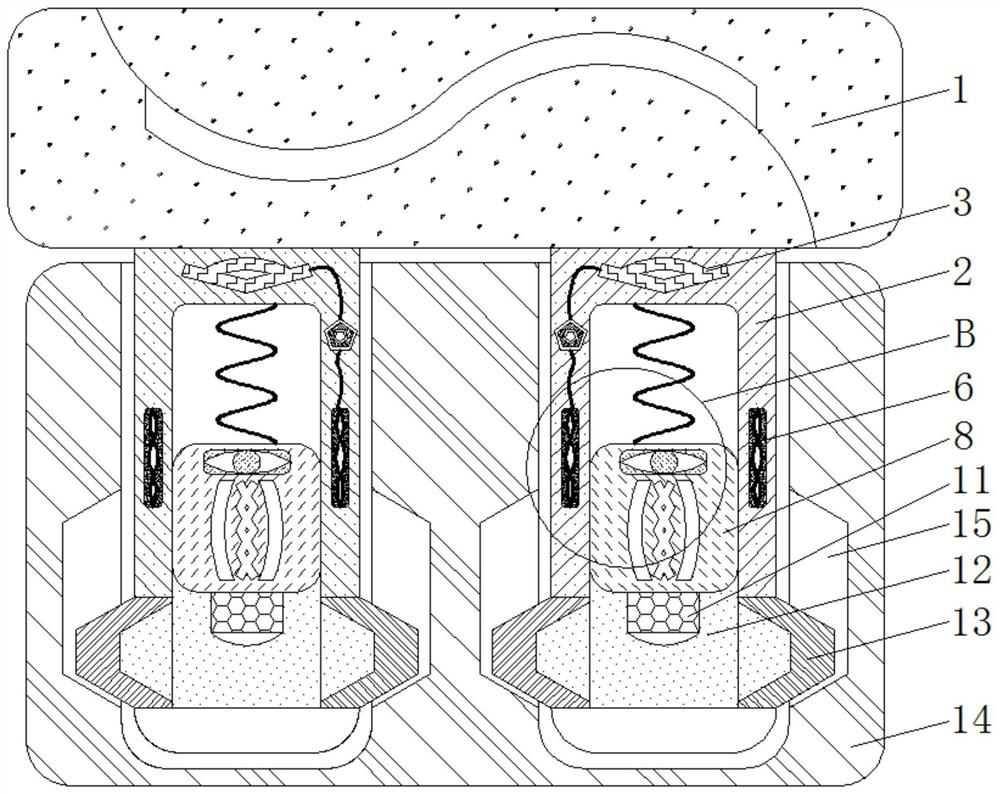

[0020] See Figure 1-4 A koji machine off-proof power plug and socket, comprising a plug material, the plug 1 is a hard and high strength material having a magnetic permeability not the plug 1 and the conductive plug 1 functions as the parts of the Insert 2 is made of copper material and material of tab 2 is rectangular parallelepiped shape, inserts 2 functions as a power transmission member and the fixing of each action, the bottom of the plug 1 is fixedly connected with two mut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com