Zero-expansion material

A zero-expansion, bi2o3 technology, applied in the field of zero-expansion materials, can solve problems such as narrow temperature range, complex manufacturing process, and low mechanical strength, and achieve the effect of simple preparation and no need for large-scale equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Using this invention to synthesize 0.7PbTiO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 . Weigh 7.6532 grams of PbO, 3.3250 grams of TiO 2 , 3.4237 g Bi 2 o 3 , and 0.5980 g of ZnO, after ball milling in ethanol solution for 1 hour, the obtained powder was dried and pressed into tablets and calcined at 700°C for 5 hours, and the calcined product was again ball milled in ethanol solution for 10 hours, and the obtained powder was dried again After pressing into sheets, and then sintering at 1200°C for 24 hours, the product obtained after cooling is the zero expansion material 0.7PbTiO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 .

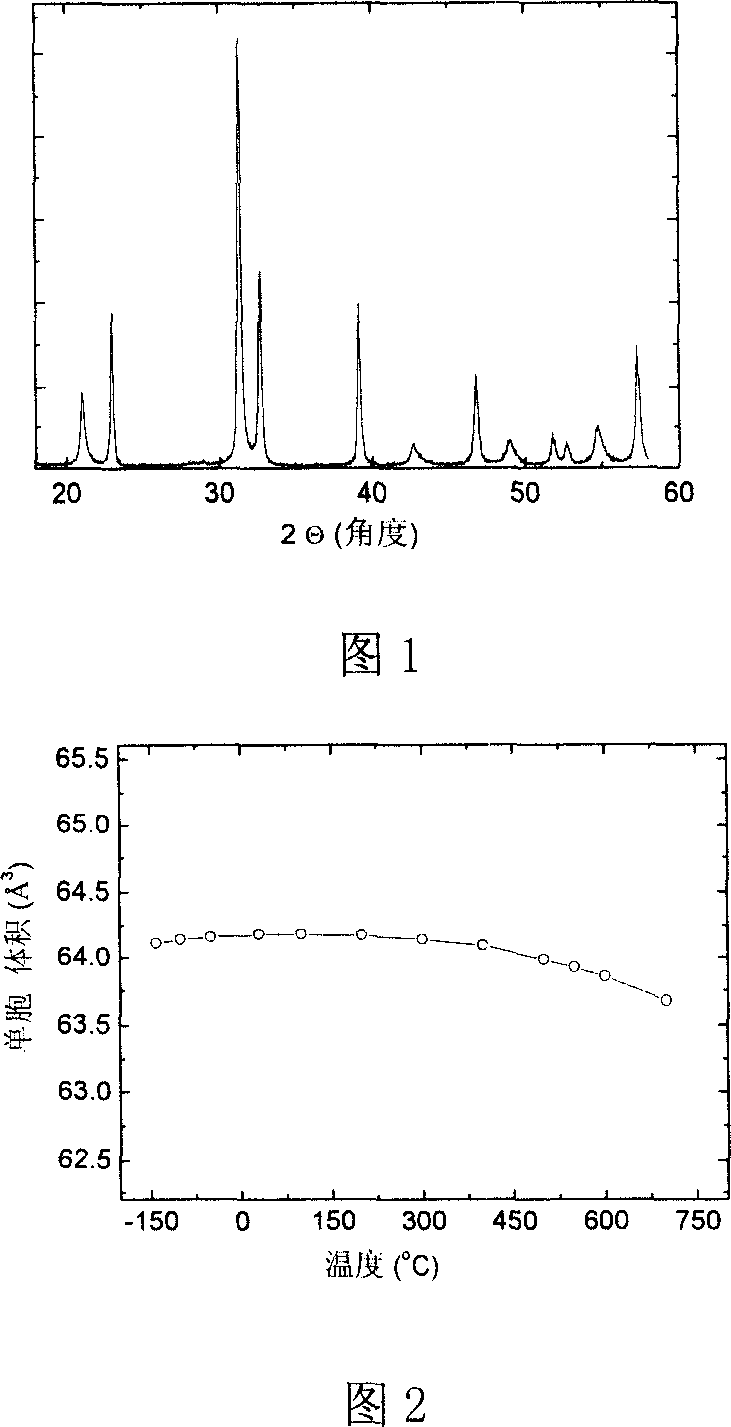

[0012] Figure 1 illustrates the 0.7PbTiO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 The compound is a single phase. Figure 2 shows the relationship between the unit cell volume and temperature of the compound. From this figure, it can be seen that the unit cell volume is basically not affected by temperature changes and has the characteristics of a zero-expansion material.

Embodiment 2

[0014] Using this invention to synthesize 0.6PbTiO 3 -0.1BiFeO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 . Weigh 5 grams of PbO, 2.2362 grams of TiO 2 , 3.4794 g Bi 2 o 3 , 0.2981 g Fe 2 o 3 And 0.4558 grams of ZnO, ball milled and mixed in ethanol solution for 24 hours, the obtained powder was dried, pressed into tablets and calcined at 800°C for 5 hours, the obtained product was cooled and ball milled again in ethanol solution for 48 hours, the obtained powder After drying, it is pressed into sheets, and then sintered at 1000°C for 2 hours, and the finished product obtained after cooling is the zero expansion material 0.6PbTiO 3 -0.1BiFeO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 .

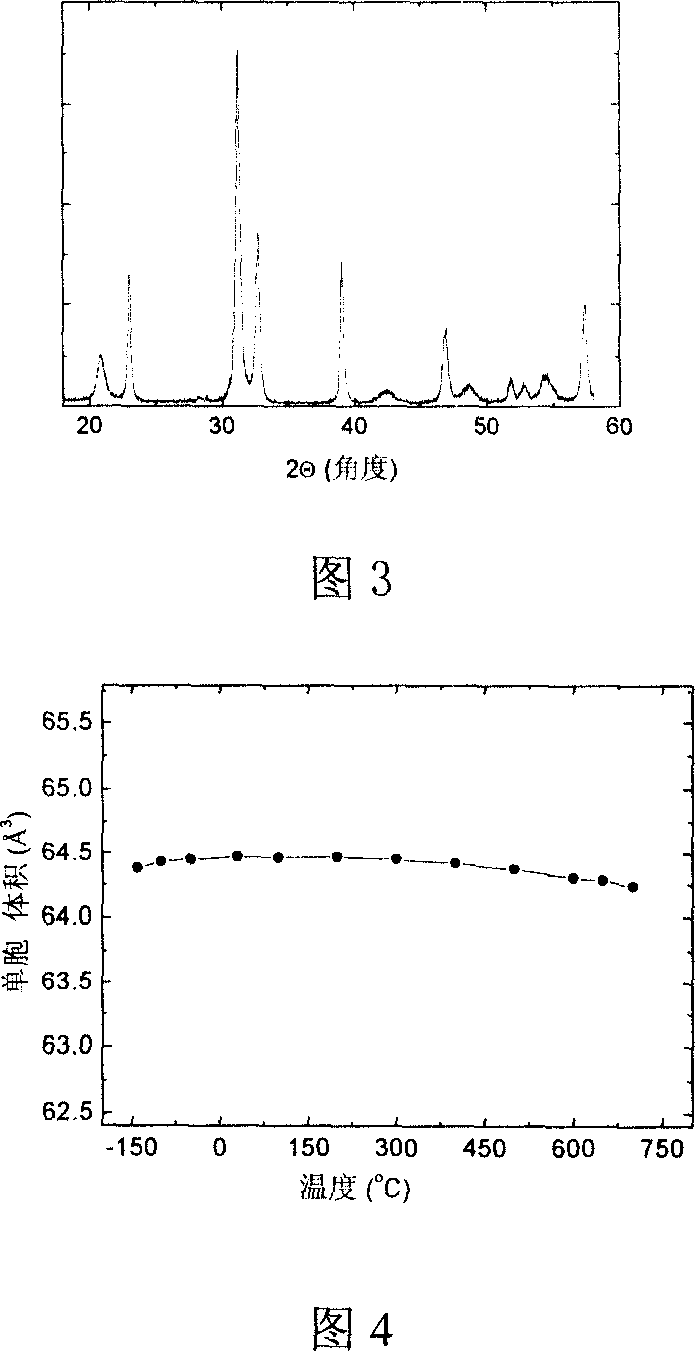

[0015] Figure 3 illustrates 0.6PbTiO 3 -0.1BiFeO 3 -0.3Bi(Zn 1 / 2 Ti 1 / 2 )O 3 The compound is a single phase. Figure 4 shows the relationship between the unit cell volume and temperature of the compound. From this figure, it can be seen that the unit cell volume is basically not affected by temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com