Impact brick making method and device

A technology of equipment and brick boxes, which is applied in the field of impact brick making methods and equipment, can solve the problems of low strength, high energy consumption, and increased investment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

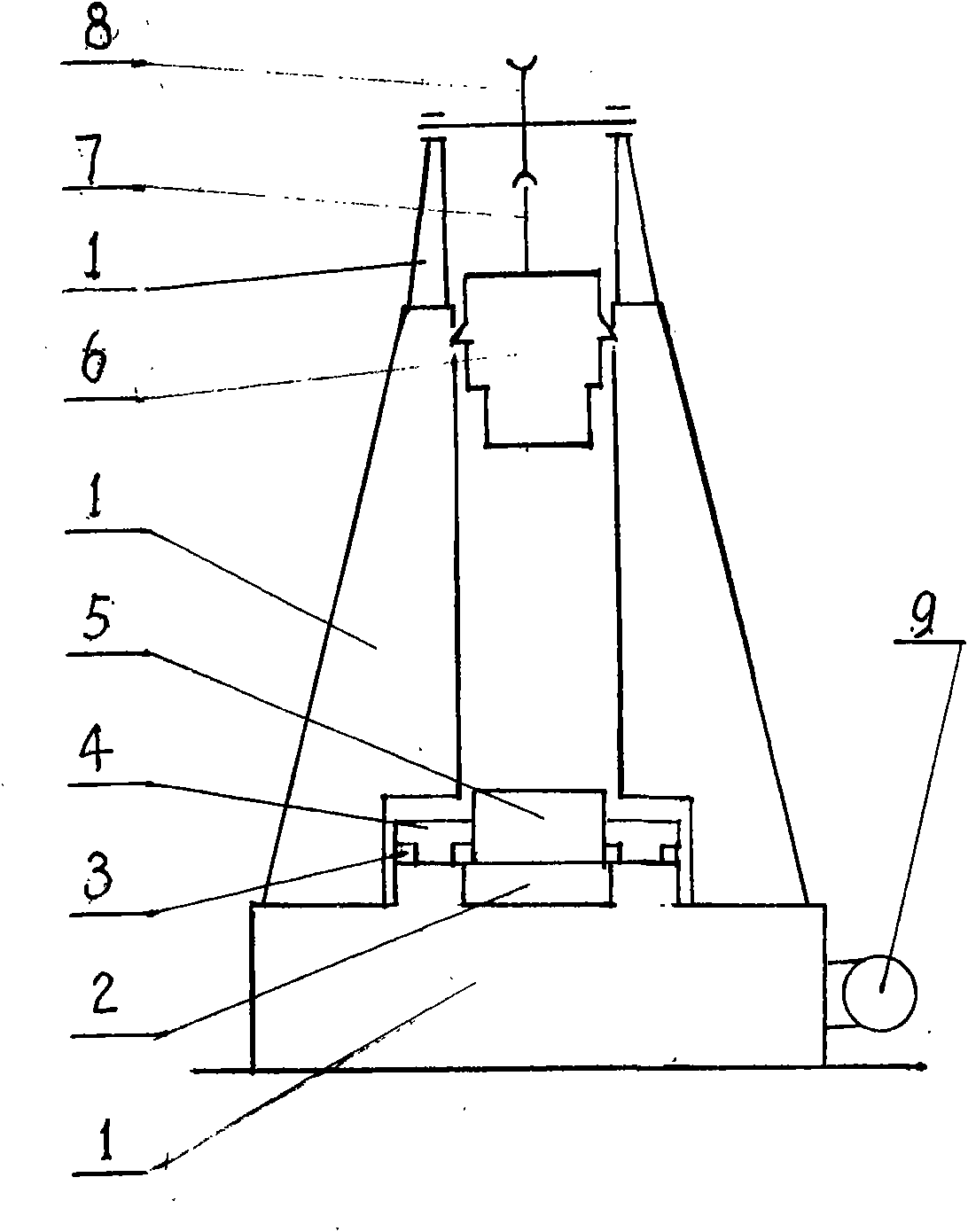

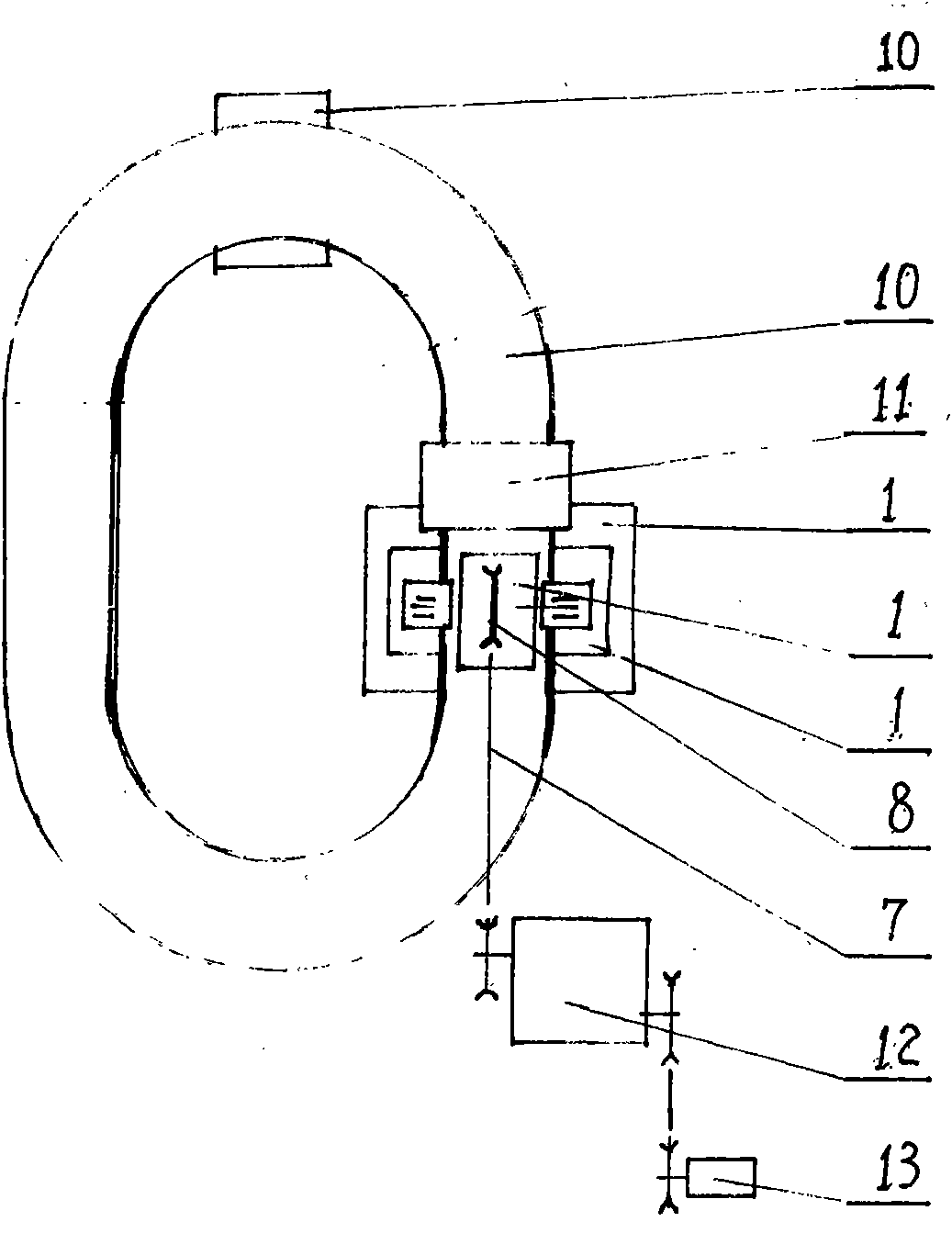

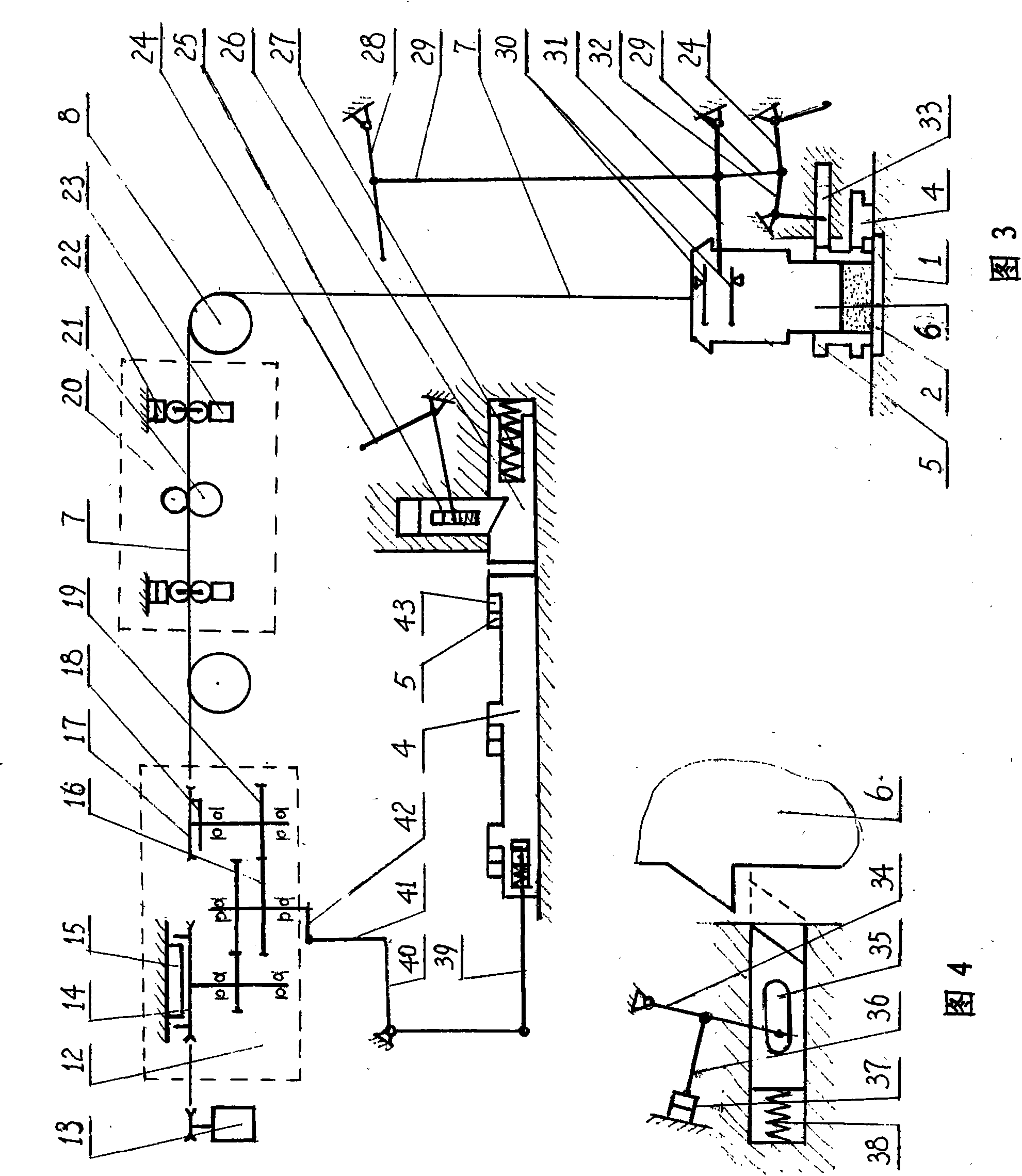

[0022] Embodiment 1, an impact brick-making method is as follows: the motor is transmitted to the lifting gear pair through variable speed, and the gear pair converts the continuous rotation transmission of the motor into intermittent rotation transmission, and lifts the gravity hammer to an appropriate level during the transmission period of the intermittent rotation transmission. At the same time, move the brick box containing the brick-making materials to the bottom of the gravity hammer. During the non-transmission period of the intermittent rotation transmission, let the gravity hammer fall freely and fix the exact position of the brick box at the same time, so that the kinetic energy impact of the fall has been placed on the brick. The brick-making materials in the box form bricks, and the driving gear attached to the lifting gear completes a working cycle every time it rotates, supplemented by other necessary mechanisms and facilities to ensure continuous brick-making.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com