Efficient pulse biological reaction device

A biological reaction device and pulse technology, which is applied in the field of high-efficiency pulse biological reaction devices, can solve the problems of high energy consumption in sludge digestion tanks, poor digestion effect of residual sludge, high operating costs, etc., and increase the gas production rate per unit of sludge , increase volume gas production, and reduce site occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

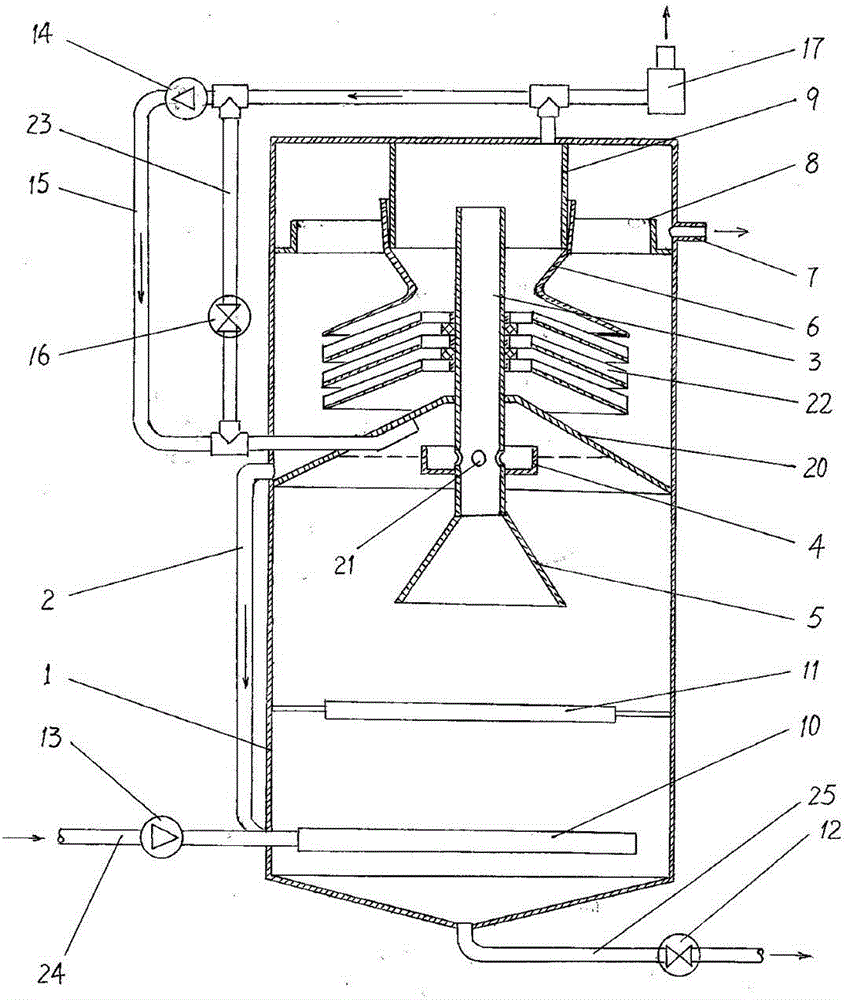

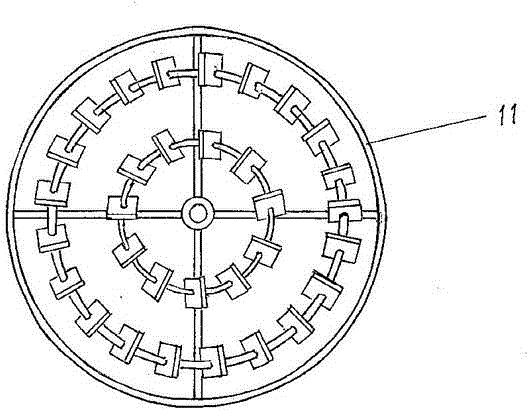

[0046] Embodiment 1: Anaerobic pulse bioreactor.

[0047] Such as figure 1 As shown, the high-efficiency pulse bioreactor of the present invention includes a closed tank body 1, which can be cylindrical, egg-shaped or square column-shaped, and the diameter-to-height ratio of the tank body can be between 0.5-8. In the middle of the tank body 1 is provided with a cone-shaped intermediate partition 20 with the conical top upward, which divides the inner cavity of the tank body 1 into an upper cavity and a lower cavity, and a connecting link is connected and fixed at the central cone top of the intermediate partition 20 . The air lift tubes 3 in the upper and lower chambers, the air lift tubes 3 can be round tubes, square tubes, elliptical tubes or polygonal tubes. On the outer wall of the airlift pipe 3 in the tank body lower cavity, a water blocking plate 4 is connected, and the water blocking plate 4 has an upward opening, and its shape can be circular, square or its shape. T...

Embodiment 2

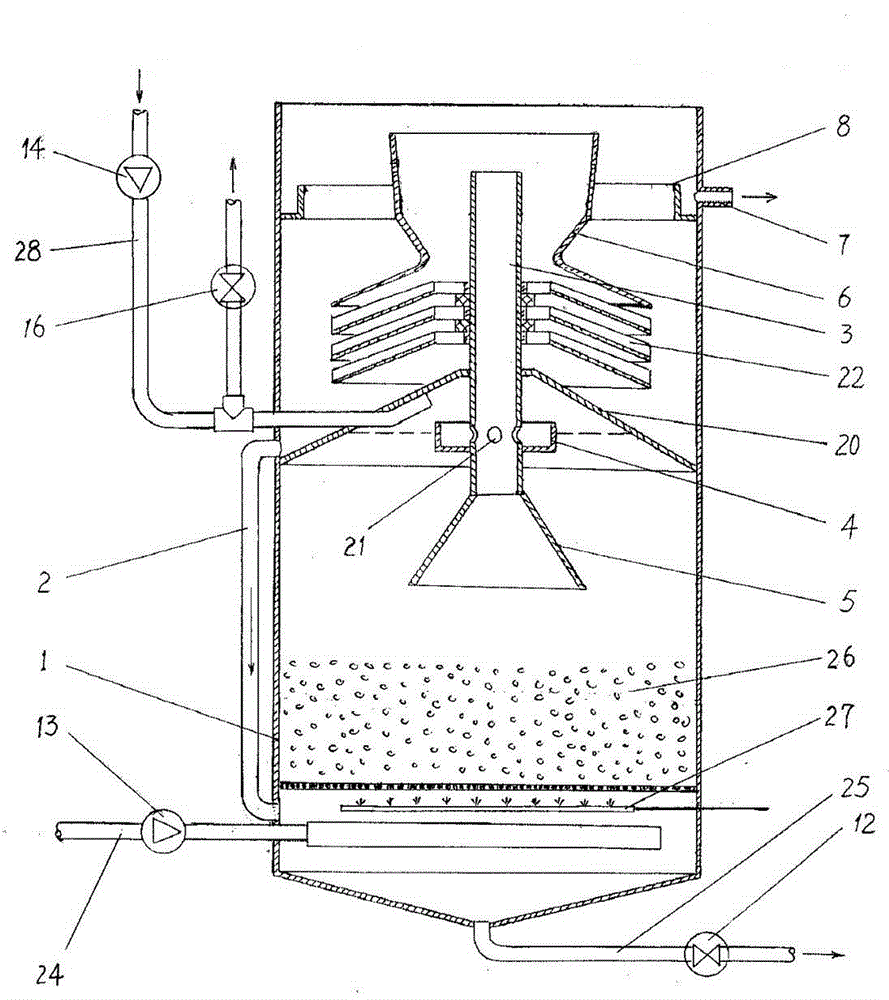

[0056] Example 2: Aerobic pulse bioreactor.

[0057] Such as image 3 As shown, the high-efficiency pulse bioreactor includes an open tank body 1, and a conical middle partition 20 is arranged in the middle of the tank body 1 to divide the tank cavity into an upper chamber and a lower chamber, and the middle partition 20 The center conical top of the center cone is pierced and fixed with the airlift tube 3 connected to the upper and lower chambers, and the lower port of the airlift pipe 9 is connected with an extension pipe extending to the lower chamber, and the lower port of the extension pipe is a straight cylinder mouth, a cone mouth or trumpet. A water blocking plate 4 is connected to the outer wall of the air lifting pipe 3 located in the lower cavity of the tank body, and an air hole 21 is opened on the air lifting pipe 3 in the water blocking plate.

[0058] A ventilation pipe 28 is plugged into the tank body 1, and the insertion end of the ventilation pipe 28 extend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com