PC component production system

A production system and component technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve the problems of road prefabricated components that cannot be transported, the impact of production scale transportation distance, and narrow factory coverage, etc., to shorten the intermediate transportation Links, convenient transition production, avoiding the effect of equipment relocation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

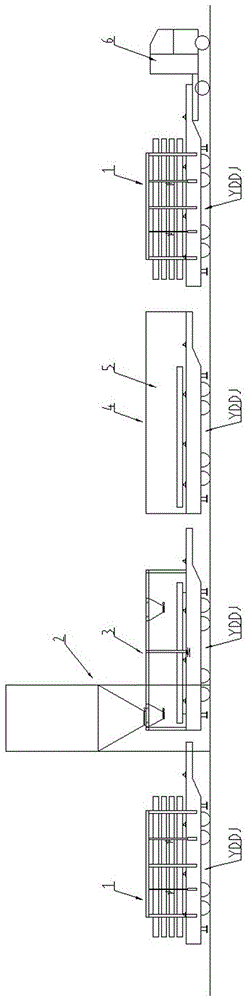

[0019] Such as figure 1 As shown, the PC component production system disclosed in this embodiment includes a mold station 1 , a mortar storage tank 2 , a cloth vibrating station 3 and a maintenance station 4 . The mold platform station 1, cloth vibrating station 3 and maintenance station 4 of this embodiment all adopt the mobile base YDDJ designed with reference to the semi-trailer. In order to ensure the stability of the mobile support on the ground during production, the mobile In addition to the wheels, there are telescopic outriggers ZT.

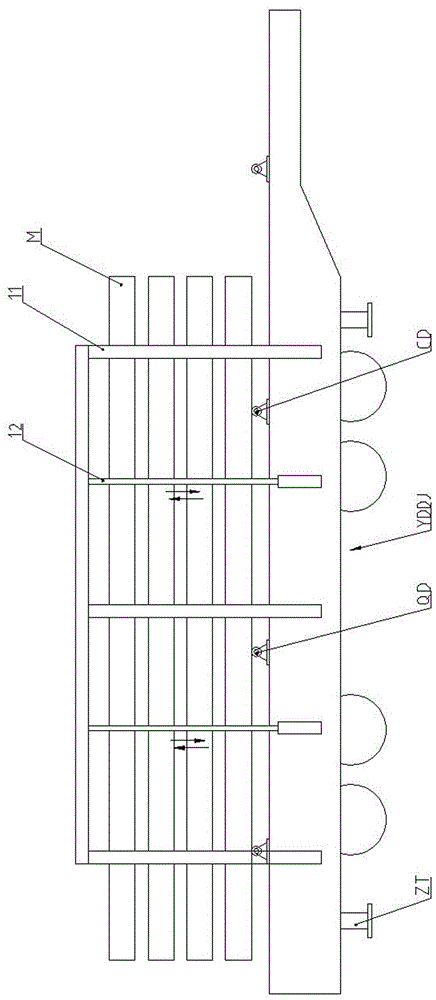

[0020] Such as figure 2 As shown, the movable underframe of the mold platform station 1 is arranged with a liftable movable support 11 and an oil cylinder 12 along the length direction of the vehicle frame. A driving roller QD and a driven roller CD are arranged on the upper side of the vehicle frame along the width direction as conveying means.

[0021] The mold table station 1 is mainly used for storing the mold table M, which is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com