Automatic green brick cutting device and cutting method thereof

An automatic cutting device and adobe technology, applied in the field of adobe cutting, can solve the problems of many structural links, reduced efficiency, and uneven shape of adobe, and achieve the effect of compact mechanism and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

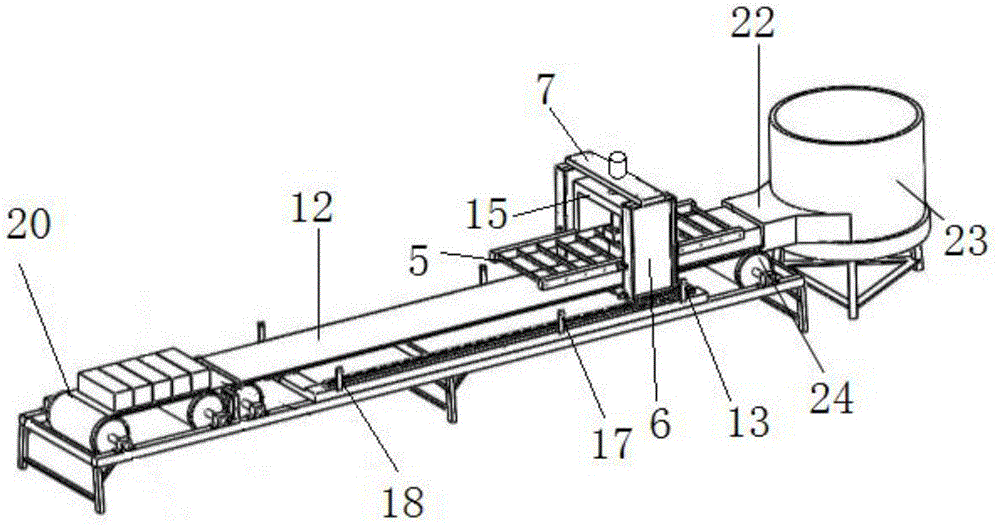

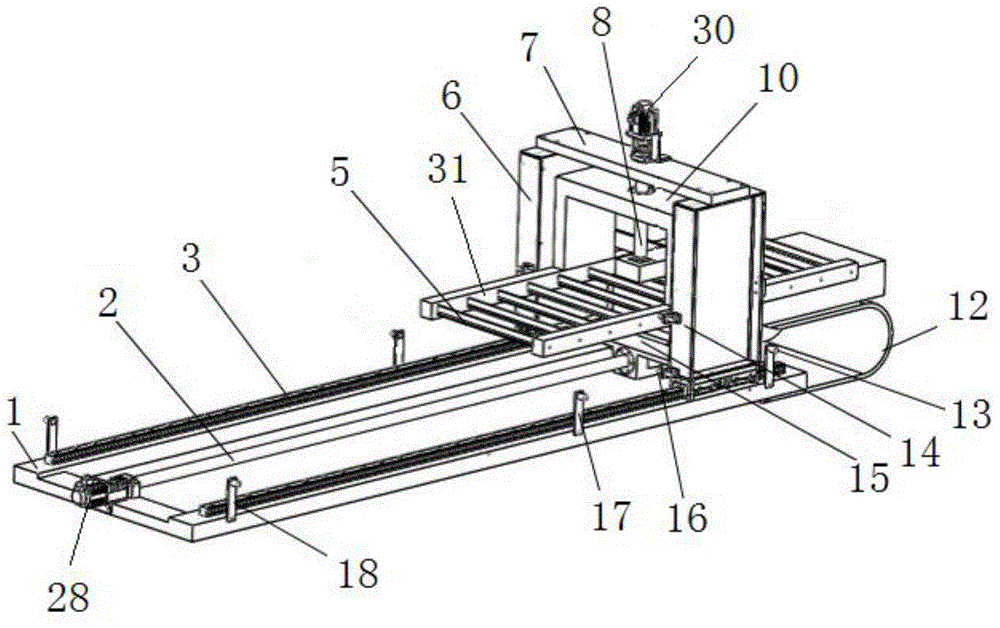

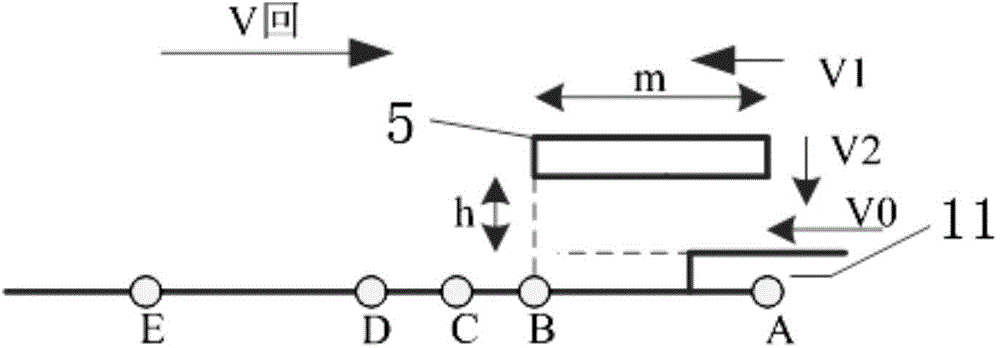

[0024] like Figure 1 ~ Figure 2 An automatic cutting device for adobe is shown, including a mud strip conveying mechanism, a moving mechanism, and a cutting mechanism arranged on the moving mechanism. When the relative speed of the moving mechanism and the mud stick conveying mechanism is zero, the cutting mechanism cuts the mud stick and pushes the cut mud stick away.

[0025] The moving mechanism includes a base 1, guide rails 3 arranged on both side arms of the base 1, sliders sliding on the two guide rails 3, support arms 6 respectively connected to the two sliders, and fixedly connected to the two support arms 6 respectively. The connection plate 15, the screw drive mechanism 2 that drives the connection plate 15 and the support arm 6 to slide through the conveying motor 28, and the tops of the two support arms 6 are connected by a crossbeam 7. The screw drive mechanism 2 is provided with a speed sensor for collecting the moving speed of the cutting mechanism.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com