Full-automatic storage battery protective screen plate continuous installation and short circuit detection system

A technology for short-circuit detection and protection net, which is used in short-circuit testing, battery assembly, and secondary battery manufacturing. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

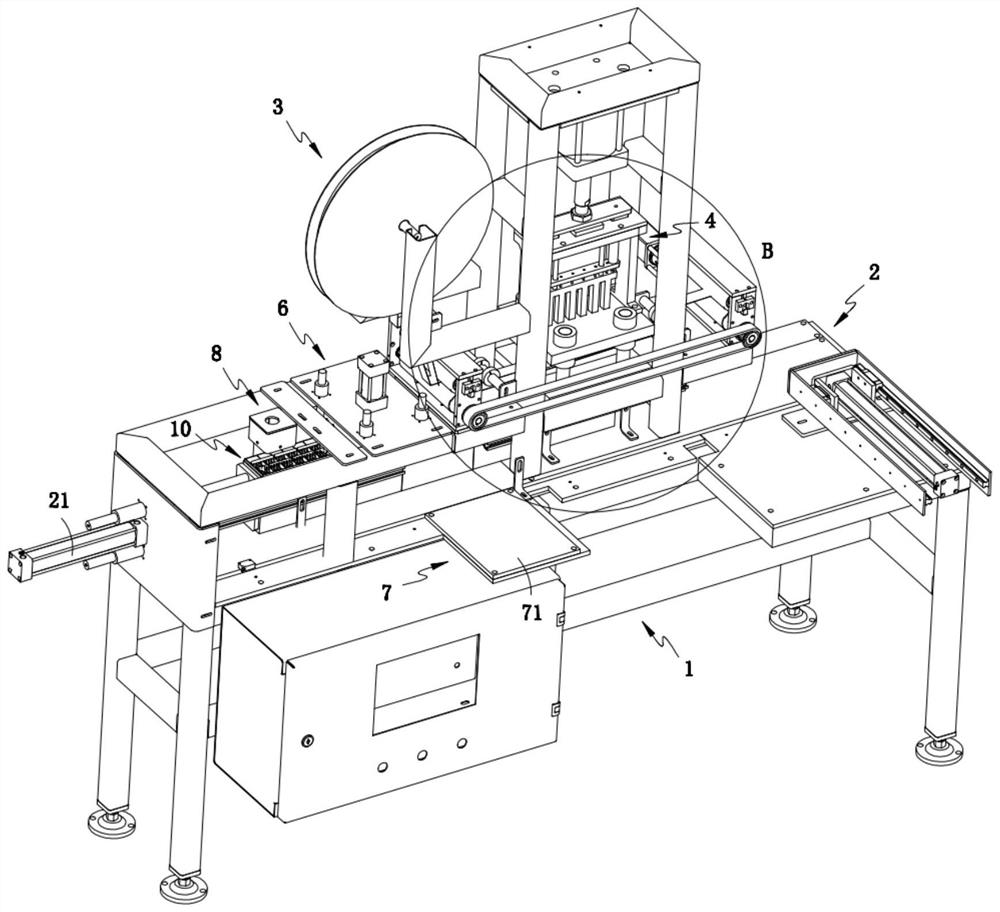

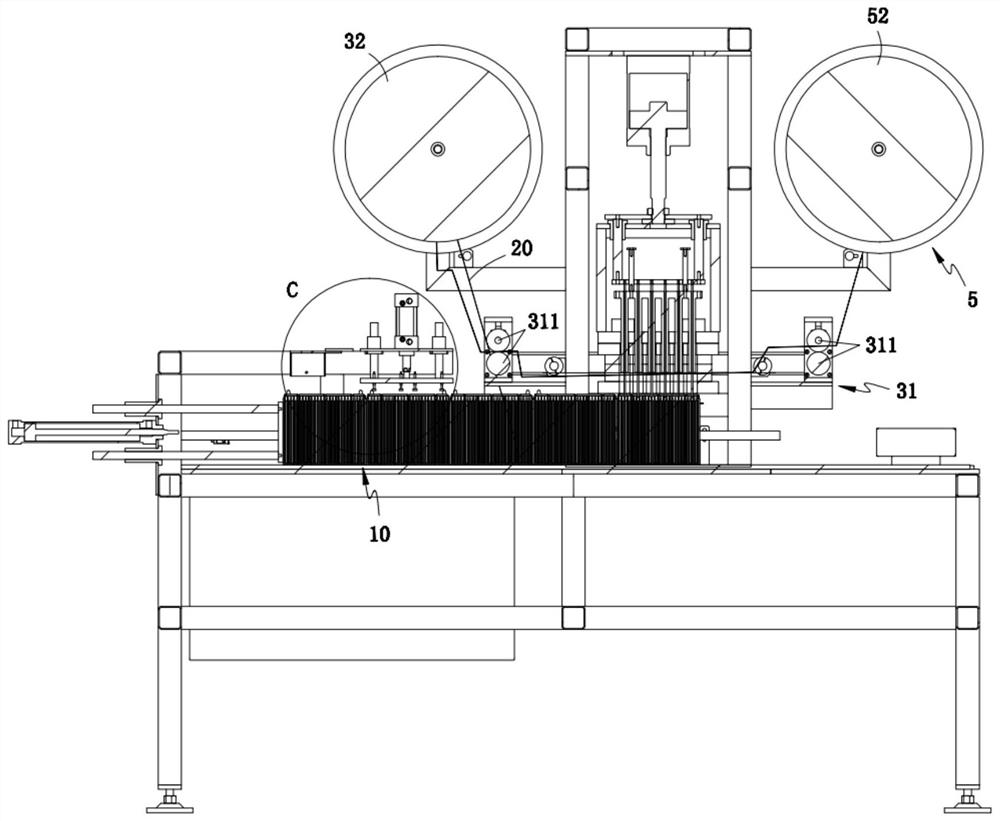

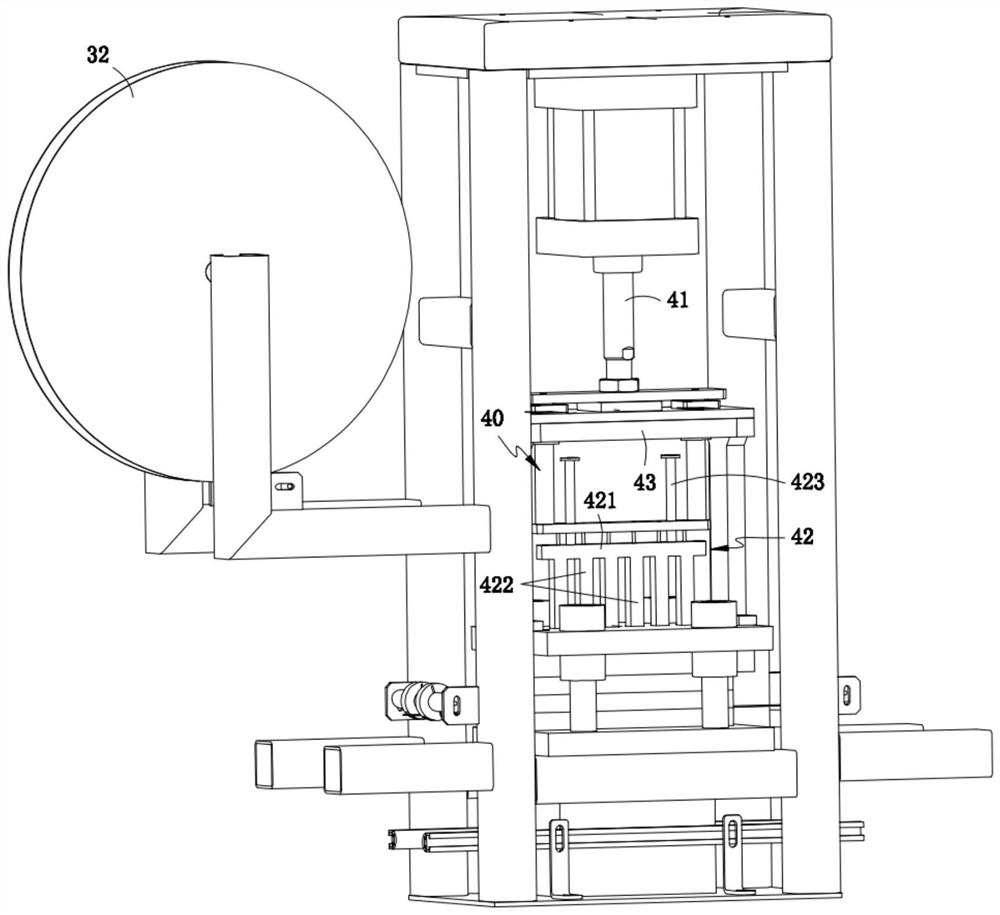

[0038] like Figure 1-2 As shown, the automatic continuous installation and short-circuit detection system for the battery protection screen includes a frame 1 and a transmission track 2 set on the frame 1 for continuous transmission of the battery 10, and also includes a transmission track 2 set on the transmission track 2. The protective net transmission mechanism 3 and the protective net panel installation mechanism 4 on the path, the protective net panel installation mechanism 4 includes a positioning unit and a cutting unit that is vertically slidably installed on the positioning unit, and the protective net transmission mechanism 3 The protective mesh belt 20 is continuously transported, and after the positioning unit moves down to position the protective mesh belt 20 through, the cutting unit moves down to cut out the protective mesh plate from the protective mesh belt 20 and position and install it on the battery 10 .

[0039] In this embodiment, the storage battery 10...

Embodiment 2

[0059] Components in this embodiment that are the same as or corresponding to those in Embodiment 1 use reference numerals corresponding to those in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0060] As preferred, such as figure 2 As shown, it also includes a protective net waste recovery mechanism 5 arranged at the waste material discharge end of the protective net belt 20, and the protective net waste recovery mechanism 5 includes a winding driving part installed on the frame 1 and is formed by the The winding drive part drives and rotates the winding roller 52 for waste winding.

[0061] In this embodiment, the cut protective net belt 20 is output from the transmission roller group 311 at the transmission end of the storage battery 10, and the waste belt can be automatically rewound by setting the protective net waste recovery mechanism 5 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com