Yarn production device for textiles

A production device and yarn technology, applied in the field of textile yarn production, can solve the problems of low degree of automation, time-consuming and laborious, cumbersome operation, etc., and achieve the effects of reducing labor costs, wide application range, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

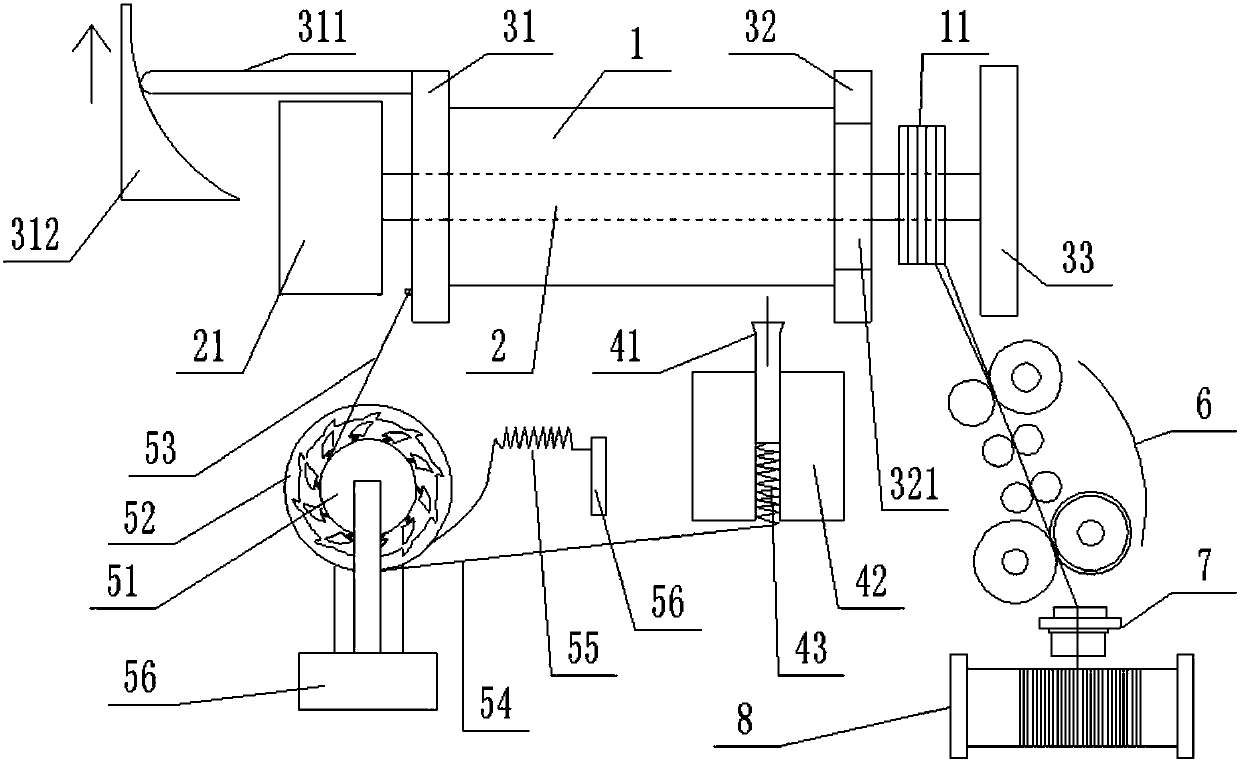

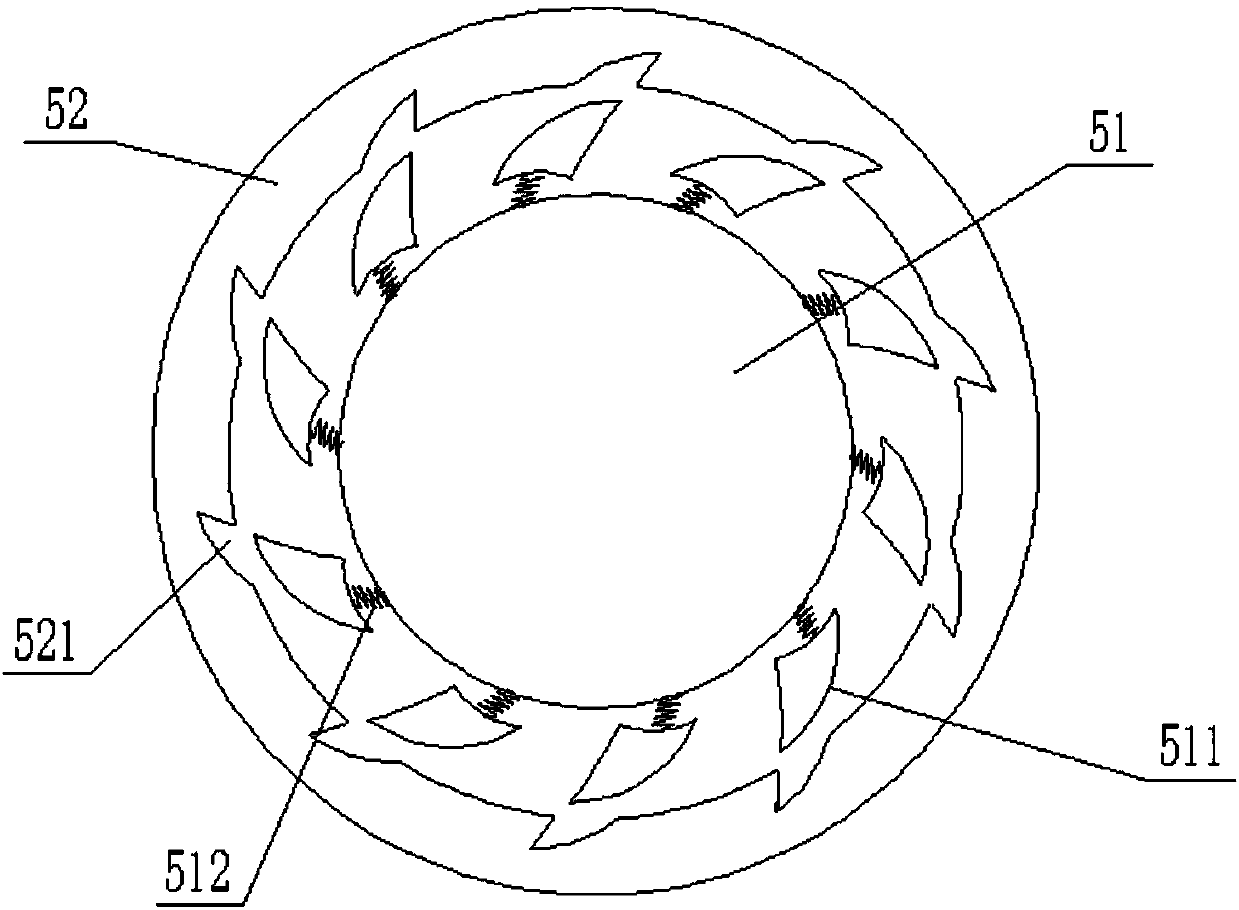

[0018] The reference signs in the drawings of the description include: surface cloth roll 1, small cloth strip roll 11, rotating shaft 2, motor 21, moving bracket 31, connecting rod 311, concave block 312, static bracket 32, through hole 321, limit Support 33, cutting knife 41, knife holder 42, first spring 43, inner wheel 51, protrusion 511, second spring 512, outer wheel 52, concave hole 521, first pulling wire 53, second pulling wire 54, extension spring 55, fixed seat 56, drafting unit 6, flyer 7, yarn roller 8.

[0019] The embodiment is basically as attached figure 1 , attached figure 2Shown: a yarn production device for weaving, including a cloth roll cutting mechanism and a yarn making mechanism, the cloth roll cutting mechanism includes a motor 21, a cloth roll fixing unit and a rotating shaft 2 for socketing a surface cloth roll 1, The cloth roll fixing unit includes a moving suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com