Stone brick cutting equipment

A cutting equipment, stone brick technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of high cutting risk, low efficiency, easy fatigue, etc., and achieve the effect of improving work efficiency and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

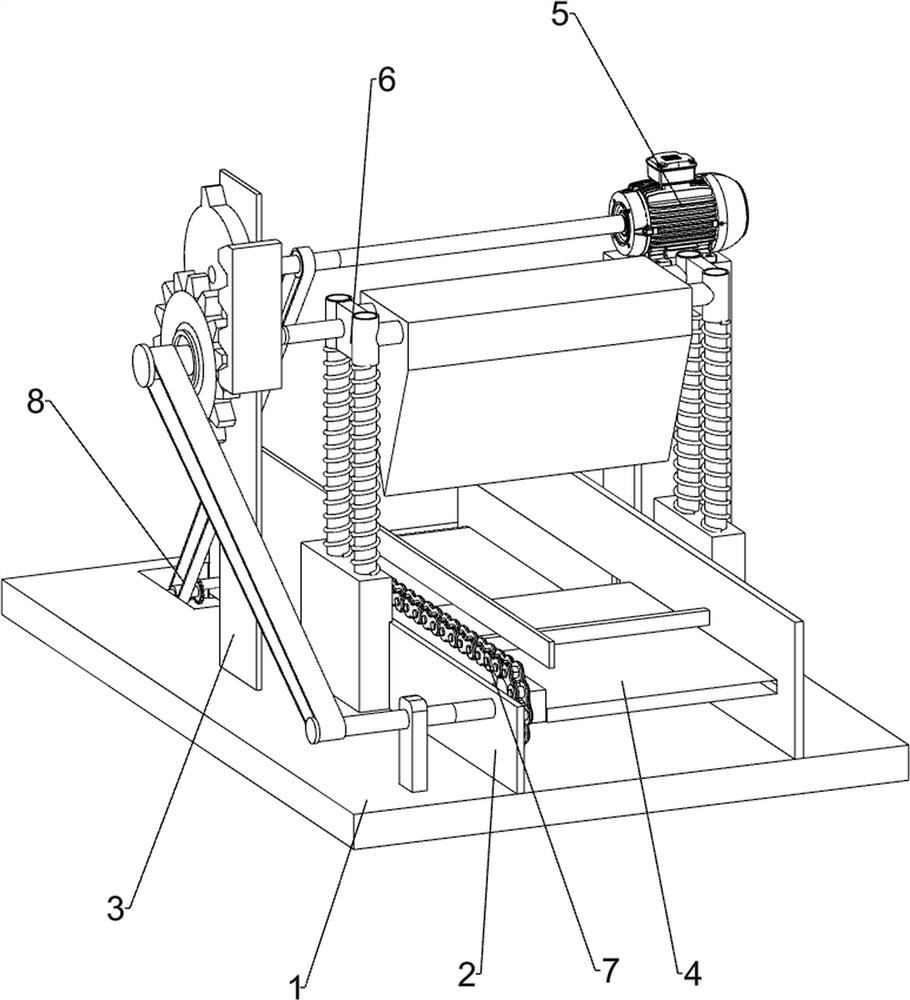

[0024] A stone brick cutting equipment such as figure 1 , 2 As shown, it includes a placement board 1, a side board 2, a bracket 3, a supporting board 4, a drive assembly 5 and a cutting assembly 6. The inner side of the middle part of the plate 2 is connected with a supporting plate 4 , the rear side of the top of the placing plate 1 is provided with a drive assembly 5 , and the middle of the top of the placing plate 1 is connected with a cutting assembly 6 .

[0025] The driving assembly 5 includes a motor 51 and a first rotating shaft 52 , the top right side of the placing plate 1 is provided with a motor 51 , the output shaft of the motor 51 is connected with a first rotating shaft 52 , and the first rotating shaft 52 is rotationally connected with the upper side of the support 3 .

[0026] The cutting assembly 6 includes a slide bar 61, a slide block 62, a return spring 63, a cutting tool 64, a rack 65 and a three-toothed gear 66, and two slide bars 61 are slidably conne...

Embodiment 2

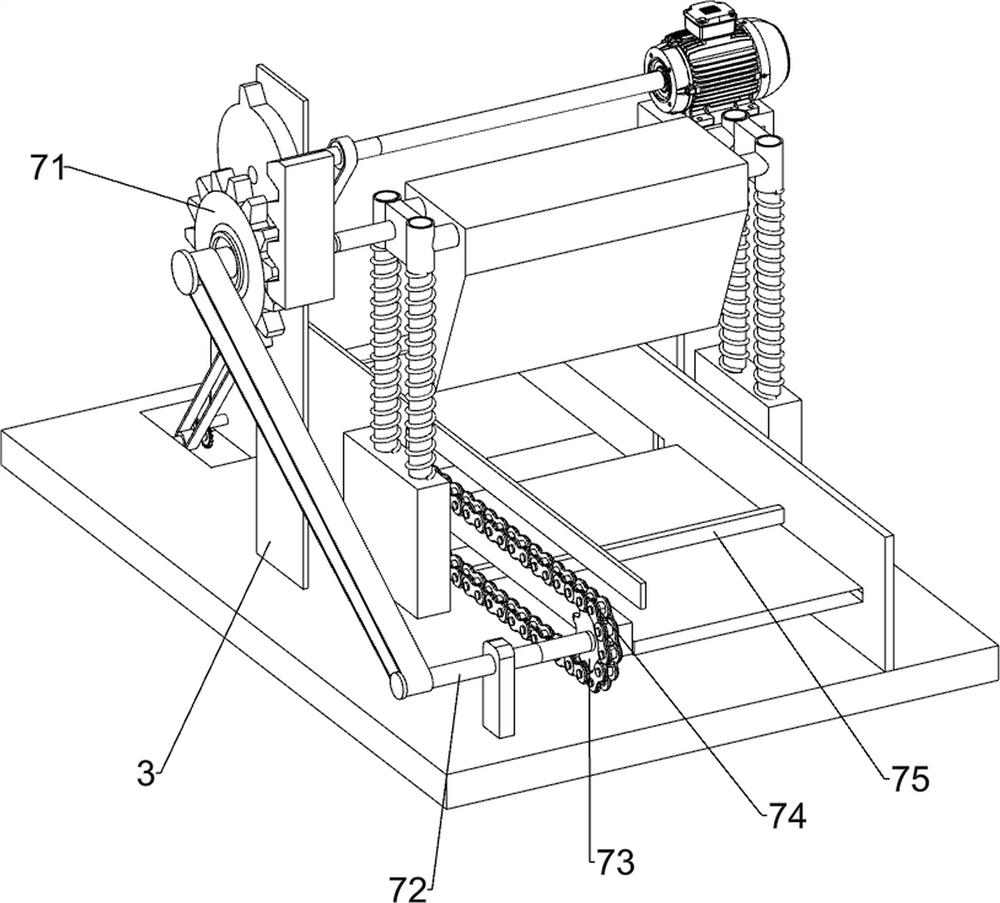

[0029] On the basis of Example 1, such as image 3 As shown, a push assembly 7 is also included, and the push assembly 7 includes a one-way gear 71, a second rotating shaft 72, a sprocket 73, a chain 74 and a push rod 75, and the left side of the bracket 3 is connected with a one-way gear 71 in a rotational manner, The one-way gear 71 meshes with the rack 65, the top front end of the placement plate 1 is rotatably connected with a second rotating shaft 72, and the second rotating shaft 72 is transmission-connected with the one-way gear 71, and the front and rear sides of the left end of the side plate 2 are rotatably connected with sprockets 73. The right end of the second rotating shaft 72 is connected with the front sprocket 73, and a chain 74 is wound between the sprockets 73 on both sides. The right end of the chain 74 is diagonally connected with two push rods 75.

[0030] When the tooth bar 65 moves upwards through the return spring 63, it drives the one-way gear 71 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com