Lightweight high-strength composite material and preparation method thereof

A technology of high-strength composite materials and reinforcing materials, which is applied in the field of lightweight and high-strength composite materials and their preparation, can solve problems such as the decline in impact resistance, and achieve the effects of reducing emissions, stable performance and small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

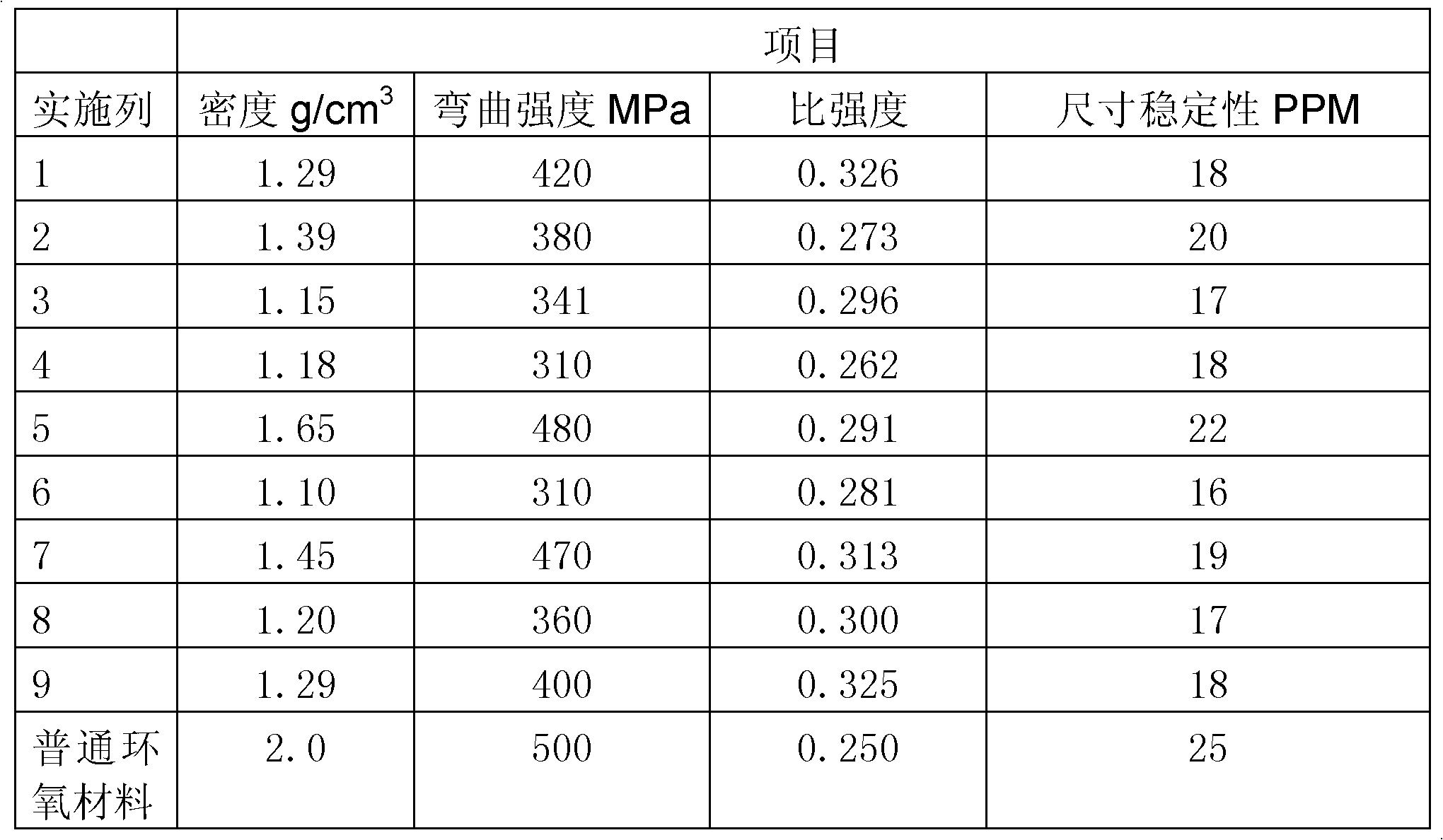

Examples

Embodiment 1

[0029] A lightweight high-strength composite material prepared by the following method:

[0030] 1) Add 23kg of hollow glass microspheres with a particle size of 900 mesh, 20kg of dimethylformamide, 0.5kg of silane coupling agent, and 0.05kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0031] 2) Prepare 125kg of bisphenol A epoxy resin, 3.2kg of electronic grade dicyandiamide, 0.09kg of dimethylimidazole, and 28kg of dimethylformamide to form a glue solution with a gel time of 220 to 225 seconds;

[0032] 3) adding the glue solution in step 2) to the hollow glass microsphere solution stirred at high speed in step 1) and stirring at high speed to form a mixed solution;

[0033] 4) Immerse 2116 cloth in the mixed solution pumped into the rubber basin, put it into an oven at a temperature of 180°C to 220°C, bake it, and then cool it to obtain a resin fluidity of 20% to 21%, and a content of 45.1 %~45.4% 2116 cloth prepreg, cut the 2116 cloth p...

Embodiment 2

[0039] A lightweight high-strength composite material prepared by the following method:

[0040] 1) Add 23kg of hollow glass microspheres with a particle size of 300 mesh, 22kg of dimethylformamide, 0.6kg of silane coupling agent, and 0.05kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0041] 2) Mix 125kg of bisphenol A epoxy resin, 2.8kg of electronic grade dicyandiamide, 0.055kg of dimethylimidazole, and 27kg of dimethylformamide into a glue solution with a gel time of 245-250 seconds;

[0042] 3) adding the glue solution in step 2) to the hollow glass microsphere solution stirred at high speed in step 1) and stirring at high speed to form a mixed solution;

[0043] 4) Immerse 1506 cloth in the mixed solution pumped into the rubber basin, put it into an oven at a temperature of 180°C to 220°C, bake it, and then cool it to obtain a resin fluidity of 18% to 19%, and a content of 40.3 %~40.7% 1506 cloth prepreg, cut the 1506 cloth prepreg in...

Embodiment 3

[0049] A lightweight high-strength composite material prepared by the following method:

[0050] 1) Add 40kg of hollow glass microspheres with a particle size of 1200 mesh, 30kg of dimethylformamide, 1kg of silane coupling agent, and 0.08kg of fluorocarbon surfactant into a high-speed disperser and stir at high speed;

[0051] 2) Mix 125kg of bisphenol A epoxy resin, 2.5kg of electronic grade dicyandiamide, 0.060kg of dimethylimidazole, and 29kg of dimethylformamide into a glue solution with a gel time of 260-270 seconds;

[0052] 3) adding the glue solution in step 2) to the hollow glass microsphere solution stirred at high speed in step 1) and stirring at high speed to form a mixed solution;

[0053] 4) Immerse 2116 cloth in the mixed solution pumped into the rubber basin, put it into an oven at a temperature of 180°C to 220°C, bake it, and then cool it to obtain a resin fluidity of 21% to 22%, and a content of 41.2 %~41.5% 2116 cloth prepreg, cut the 2116 cloth prepreg int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com