Production line and method for manufacturing building decorative sheet

A technology for building decoration and production line, which is applied to roofs using tiles/slate tiles, roofs using flat/curved panels, buildings, etc., and can solve problems such as high cost, difficult industrial production, and complex manufacturing process for building decorative panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

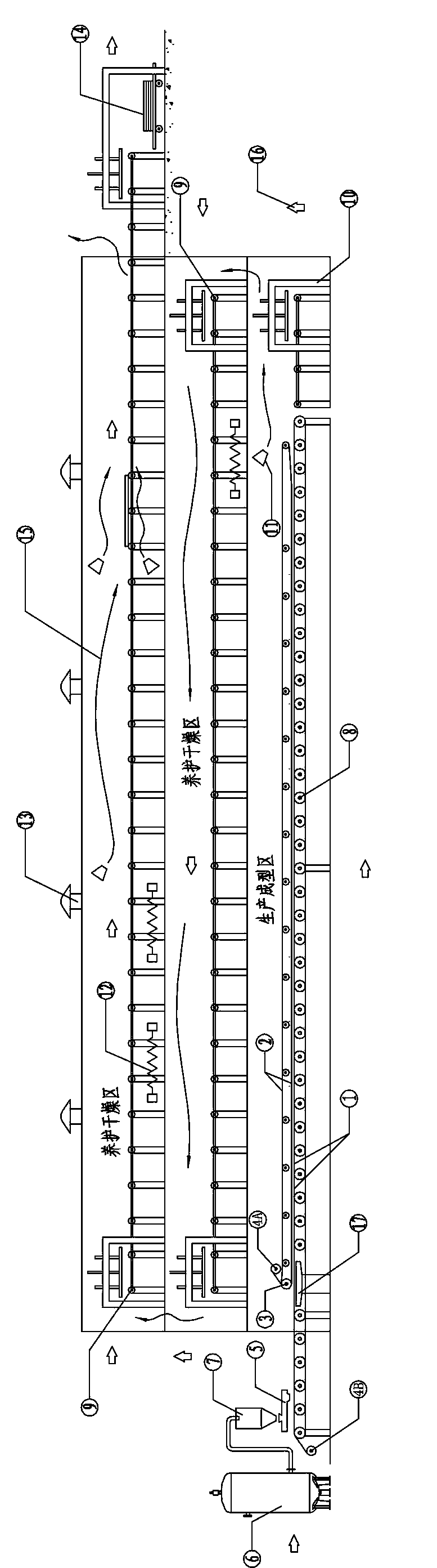

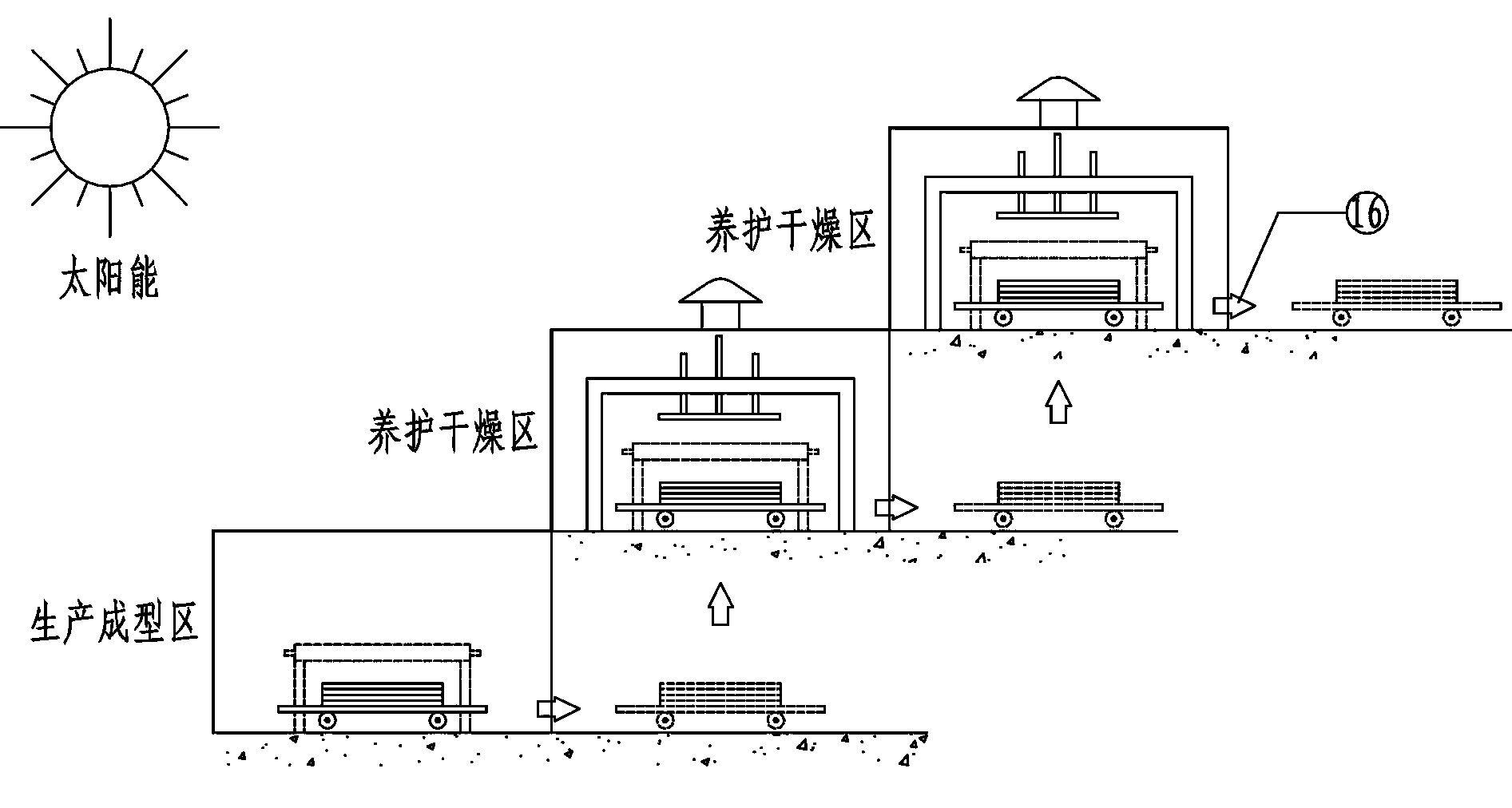

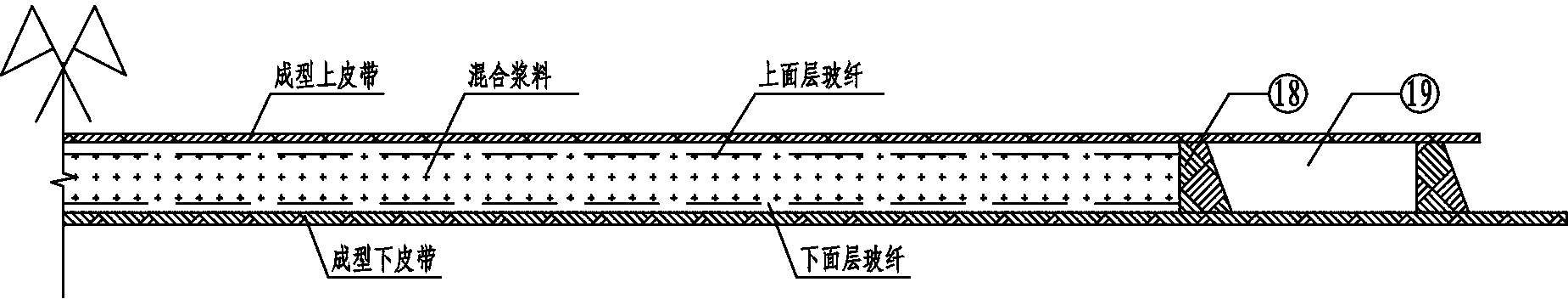

[0093] The following will refer to the attached Figure 5 The manufacturing process of the water-resistant board as the building decoration board is described in detail. figure 1 The direction of the process flow of the present invention is shown with reference numeral 16 .

[0094] The main raw material powder ash for making water-resistant board is composed of desulfurized gypsum, slag powder and cement. The filling amount of gypsum is relatively large, mainly because of the quick-setting characteristics of gypsum and the low drying shrinkage value of the finished product. The drying shrinkage value is The most critical technical data index required by the prefabricated building structure determines the main factor of whether the appearance of the prefabricated building structure is cracked. At present, only gypsum has a low dry shrinkage value among the known building cementitious materials, so the main The material is gypsum, and in order to maintain a low dry shrinkage v...

Embodiment 2

[0182] The difference from Example 1 is that the raw material additives for making water-resistant boards also include PVA (polyvinyl alcohol). After a large number of experiments, the comparison results of water-resistant board experiments shown in Table 1 are obtained.

[0183] Comparison results of water-resistant board experiments

[0184] Table 1. Test sample block: 250×250×17

[0185]

[0186] Note: the powder ash in the table is 1 part

[0187] According to the above table 1, the optimal ratio of raw materials for water-resistant boards is: fly ash + 70% water + 5% saw foam + 1.4% PVA + upper and lower glass fibers, flexural strength 10-12, bulk density 1050-1100, initial setting time 8-10min, high flexural strength, short initial setting time, and less cost increase.

Embodiment 3

[0189] The difference from Example 1 is that the additives used in making the water-resistant board include PVA (polyvinyl alcohol) and waterproofing agent. After a large number of experiments, the comparison results of the water-resistant board experiments shown in Table 2 are obtained.

[0190] Table 2. Comparison of water absorption in different proportions

[0191]

[0192] Note: the powder ash in the table is 1 part

[0193] It can be known from the above table 2 that in terms of the water resistance of the water-resistant board, the best ratio of raw materials for the water-resistant board is: powder ash + 70% water + 5% saw foam + 1.4% PVA + 3% waterproofing agent, after soaking in water for 1 Hours, the water absorption rate is only 10-15%, and it will not have a good decorative effect of efflorescence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com