Curve staring method of concrete curve jacking pipe

A concrete and curve technology, applied in the direction of earthwork drilling, pipes, rigid pipes, etc., can solve the problems of difficulty in opening and bending correction of curved pipe jacking, and the inability of correction cylinder to complete the correction operation, saving construction time, achieving significant economic benefits and reducing The effect of space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

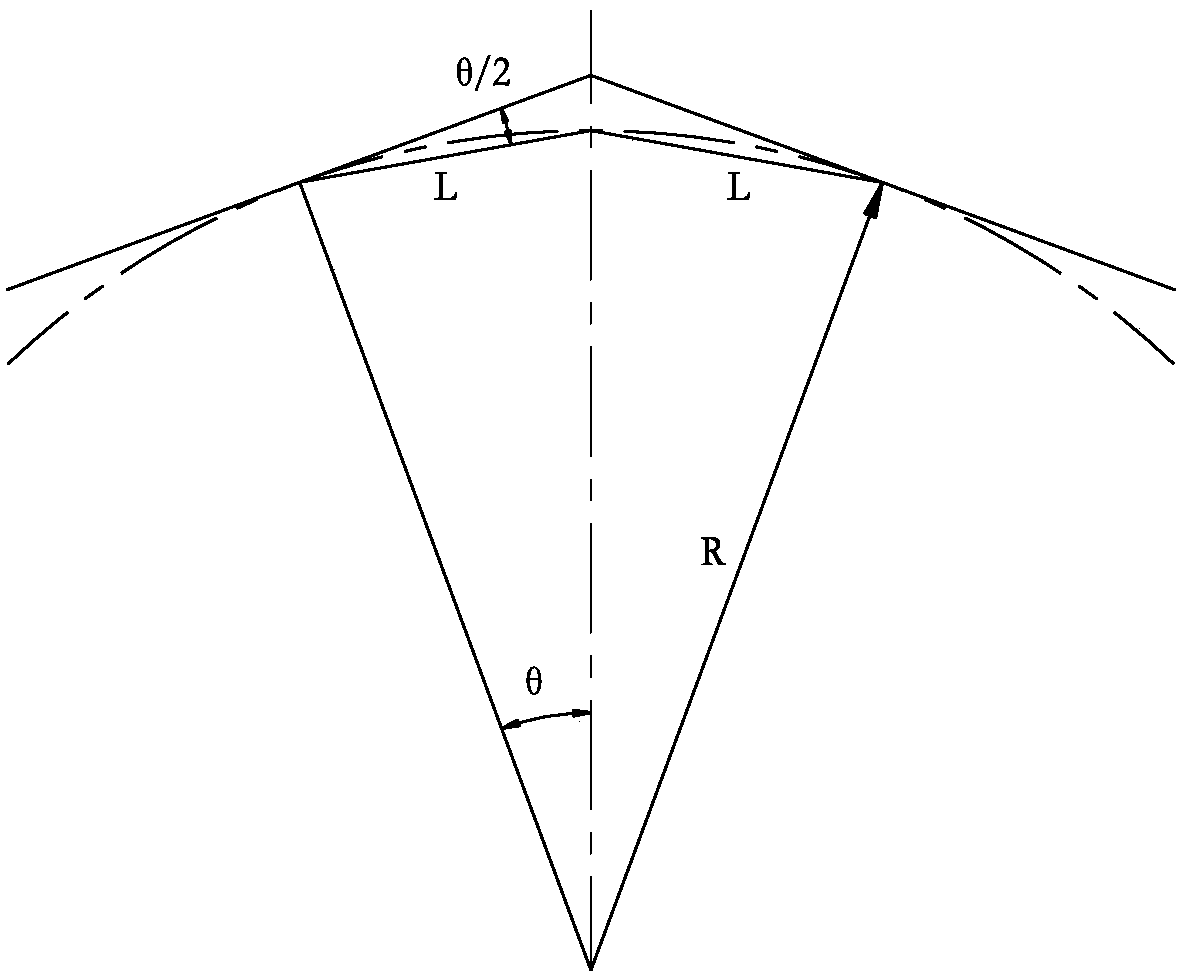

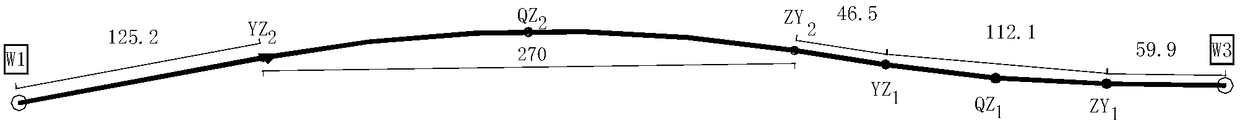

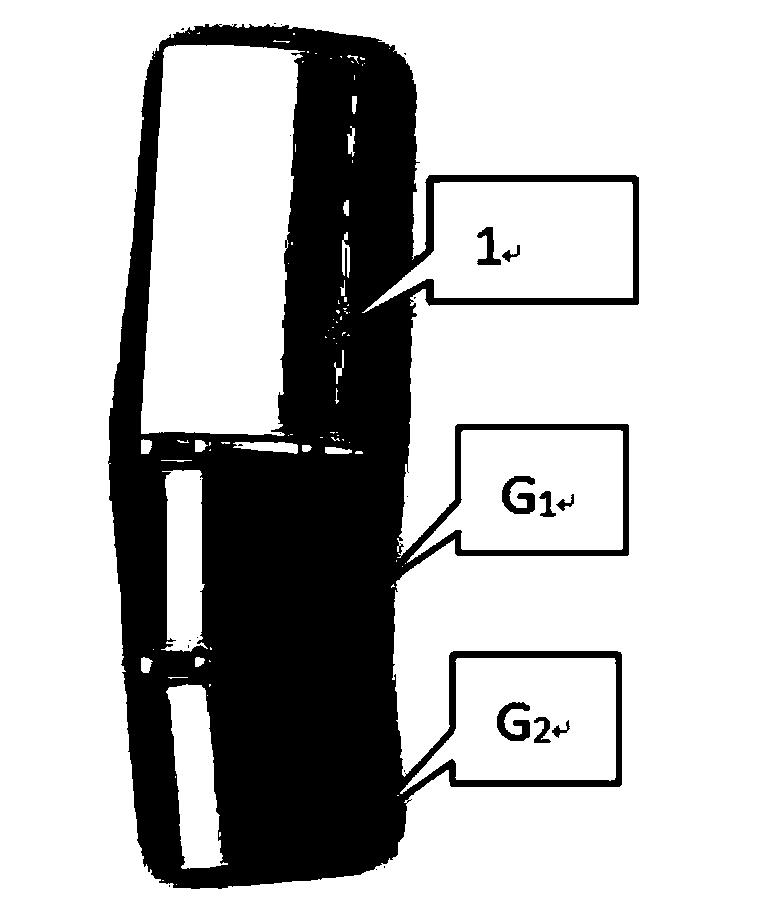

[0030] Such as figure 1 As shown, concrete curved pipe jacking construction usually includes curved section jacking construction and straight line section jacking construction. Concrete curved pipe jacking concrete curved pipe jacking includes pipe jacking machines 1, A section of open pipe G 1 And the second section of Kaiqu pipe G 2 . During the concrete pipe jacking construction, the socket of the concrete F pipe is mainly relied on for turning, so that during the construction process of the curved section, the concrete pipe jacking construction is carried out with a stable radius of curvature. Concrete curved pipe jacking Specifically, multiple concrete pipe jacking pipe joints form a curved pipe joint, and the axis of the curved pipe joint is a circular arc curve from a macroscopic point of view. In fact, it is a broken line formed by multiple concrete pipe joints. A portion of a polygon, the sides of which are the pipe lengths. Before construction, the central angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com