High inclination-angle undulating flange belt conveyor capable of conveying roller compacted concrete

A technology of roller compacted concrete and large inclination angle, which is applied in the direction of conveyor objects, transportation and packaging, cleaning devices, etc., and can solve the problems of low frequency and small amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

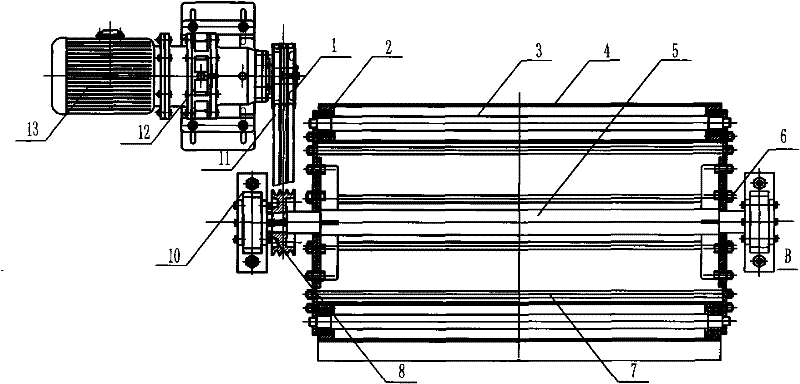

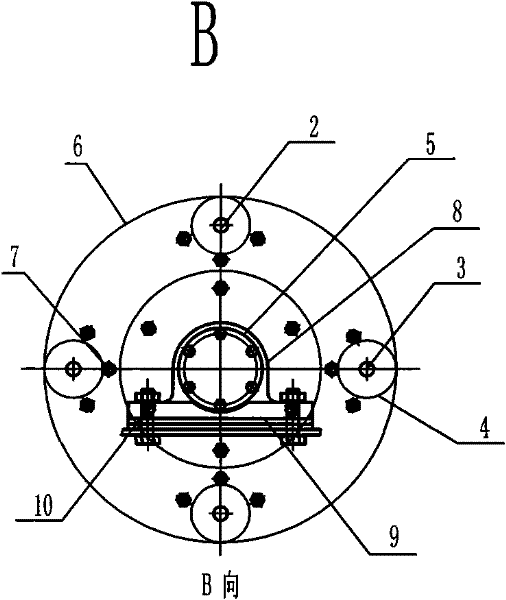

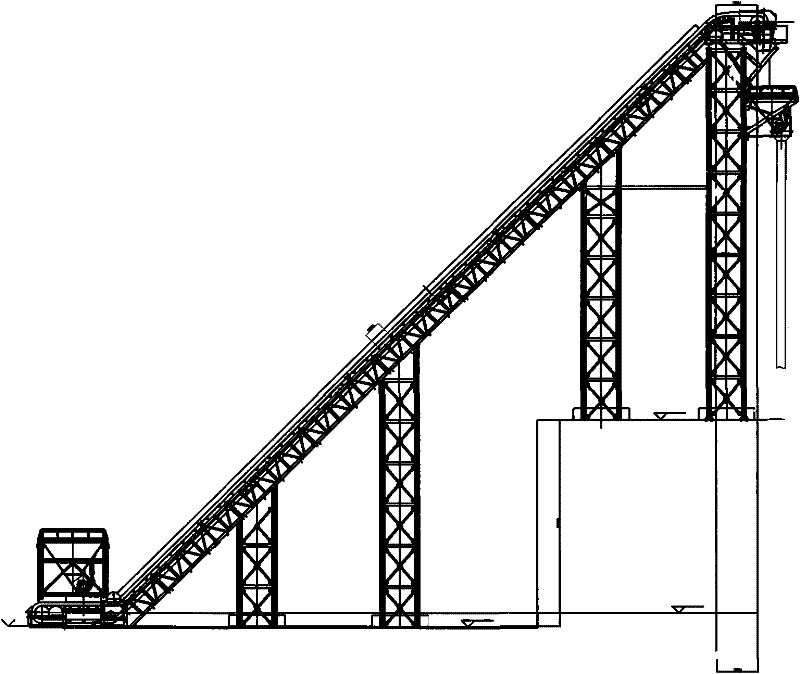

Embodiment 1

[0114] The large-inclination corrugated sidewall belt conveyor capable of transporting roller compacted concrete in this embodiment, such as image 3 As shown, it includes the upper horizontal section, the lower horizontal section and the inclined section. The upper horizontal section and the inclined section are connected by a convex arc section frame, and the lower horizontal section and the inclined section are connected by a concave arc section frame; Figure 4 As shown, the lower horizontal section includes the middle frame 11 of the material receiving section, the buffer support roller 14, the deviation switch 15, the material guide trough 16, the concave arc section frame 17, the pressing wheel device 18, the reversing roller 19 and the pull rope switch 20 , the connection relationship between the components is the same as that of the corresponding components of the existing large-inclination wave-shaped sidewall belt conveyor. The position of the inclined section of th...

Embodiment 2

[0126]The large-inclination corrugated sidewall belt conveyor capable of transporting roller compacted concrete in this embodiment, such as image 3 As shown, it includes the upper horizontal section, the lower horizontal section and the inclined section. The upper horizontal section and the inclined section are connected by a convex arc section frame, and the lower horizontal section and the inclined section are connected by a concave arc section frame; Figure 4 As shown, the lower horizontal section includes the middle frame 11 of the material receiving section, the buffer support roller 14, the deviation switch 15, the material guide trough 16, the concave arc section frame 17, the pressing wheel device 18, the reversing roller 19 and the pull rope switch 20 , the connection relationship between the components is the same as that of the corresponding components of the existing large-inclination wave-shaped sidewall belt conveyor. The position of the inclined section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com