A method for testing and controlling process parameters of robot resistance spot welding

A process parameter, resistance spot welding technology, applied in resistance welding equipment, welding monitoring devices, manufacturing tools, etc., can solve the problems of little reference, low work efficiency, poor safety performance, etc., to improve operational safety performance, reduce Human participation and the effect of reducing human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

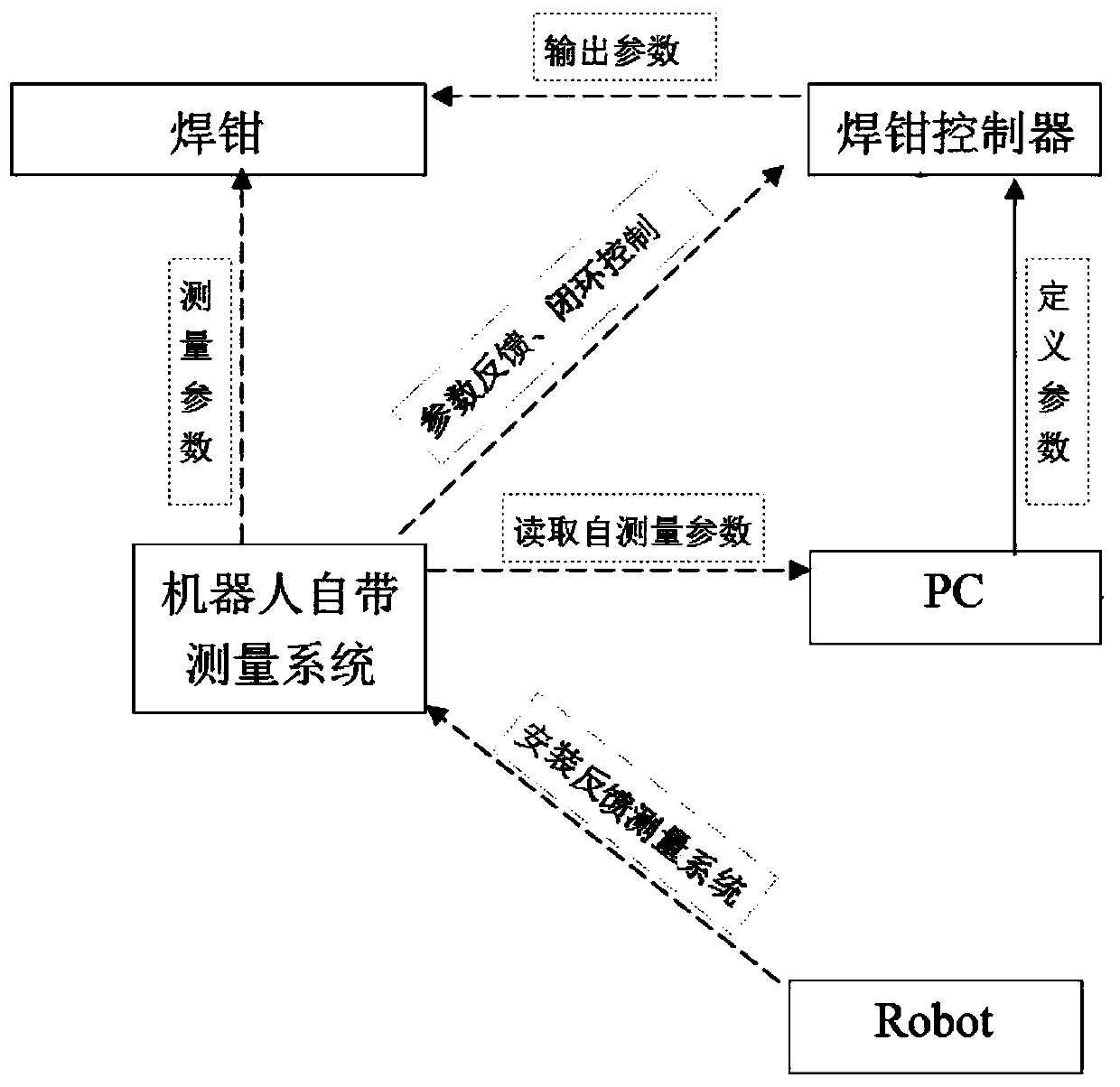

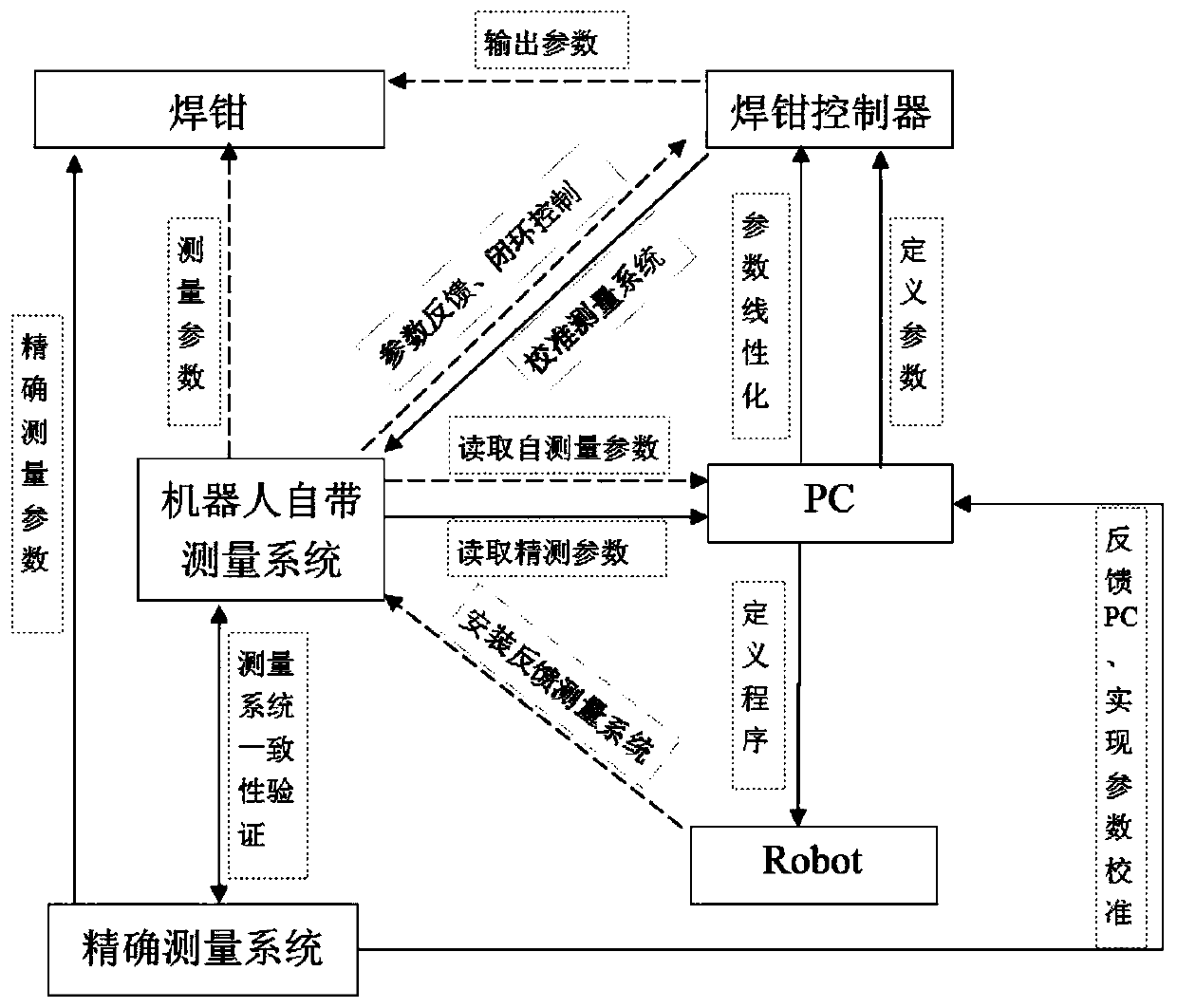

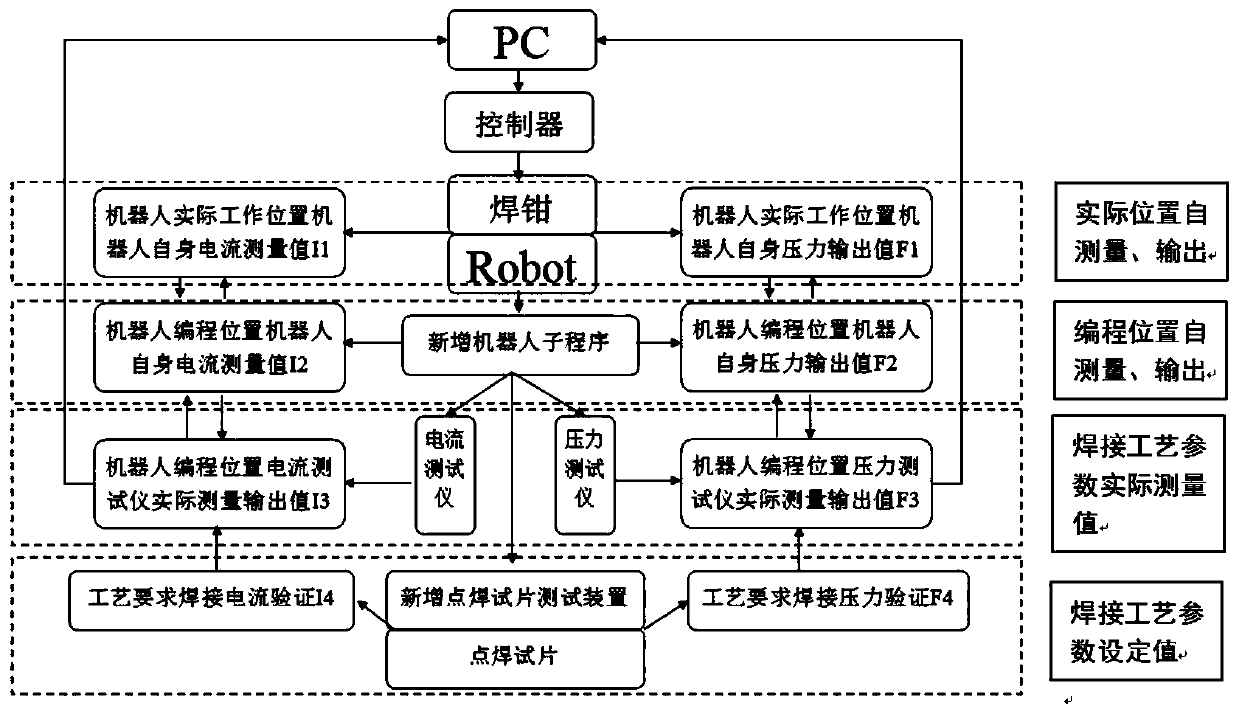

[0042] see figure 2 and image 3 , the present invention provides a kind of robot resistance spot welding process parameter testing and control method, comprises the following steps:

[0043] Step 1. Measurement position transfer verification. It is very cumbersome to measure the welding current and welding pressure at the actual welding position. Through robot programming, the welding position is transferred to a position that is convenient for operation, and the welding trajectory programming is realized;

[0044] The measurement of the welding current should be measured at the actual spot welding position of the workpiece. For robot welding, the welding tongs cannot be moved to the position we think is convenient for measurement without programming.

[0045] Step 2. Verify that the position transfer does not change the parameter output. Through the measurement of the empty spot (no weldment) and the actual spot welding, there is no change in the welding current change, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com