Electric safety test follower device for air conditioner sub-machine

A technology of follow-up device and safety test, applied in the direction of measuring device, measuring electricity, analyzing materials, etc., can solve problems such as affecting production efficiency, worker safety hazards, low work efficiency, etc., to avoid residual current, maintain continuous operation, maintain a lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

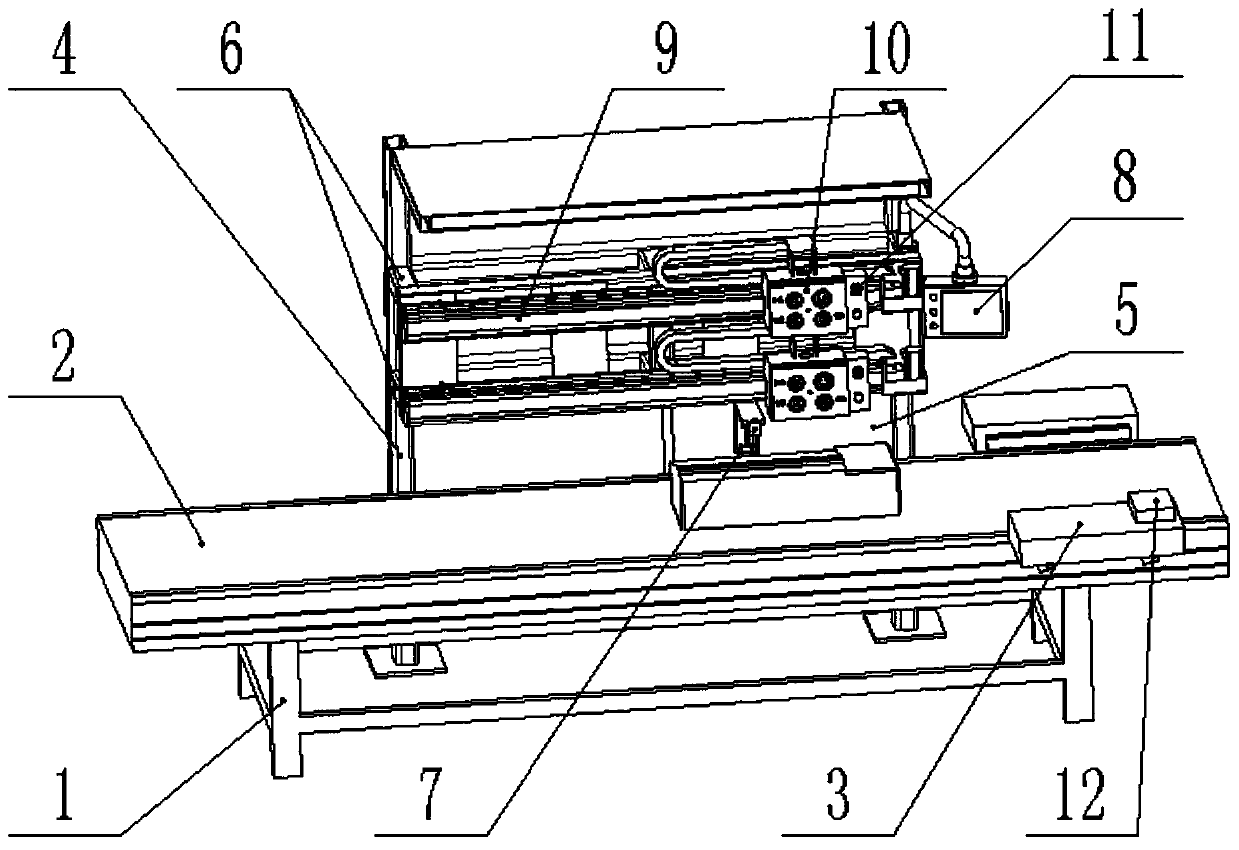

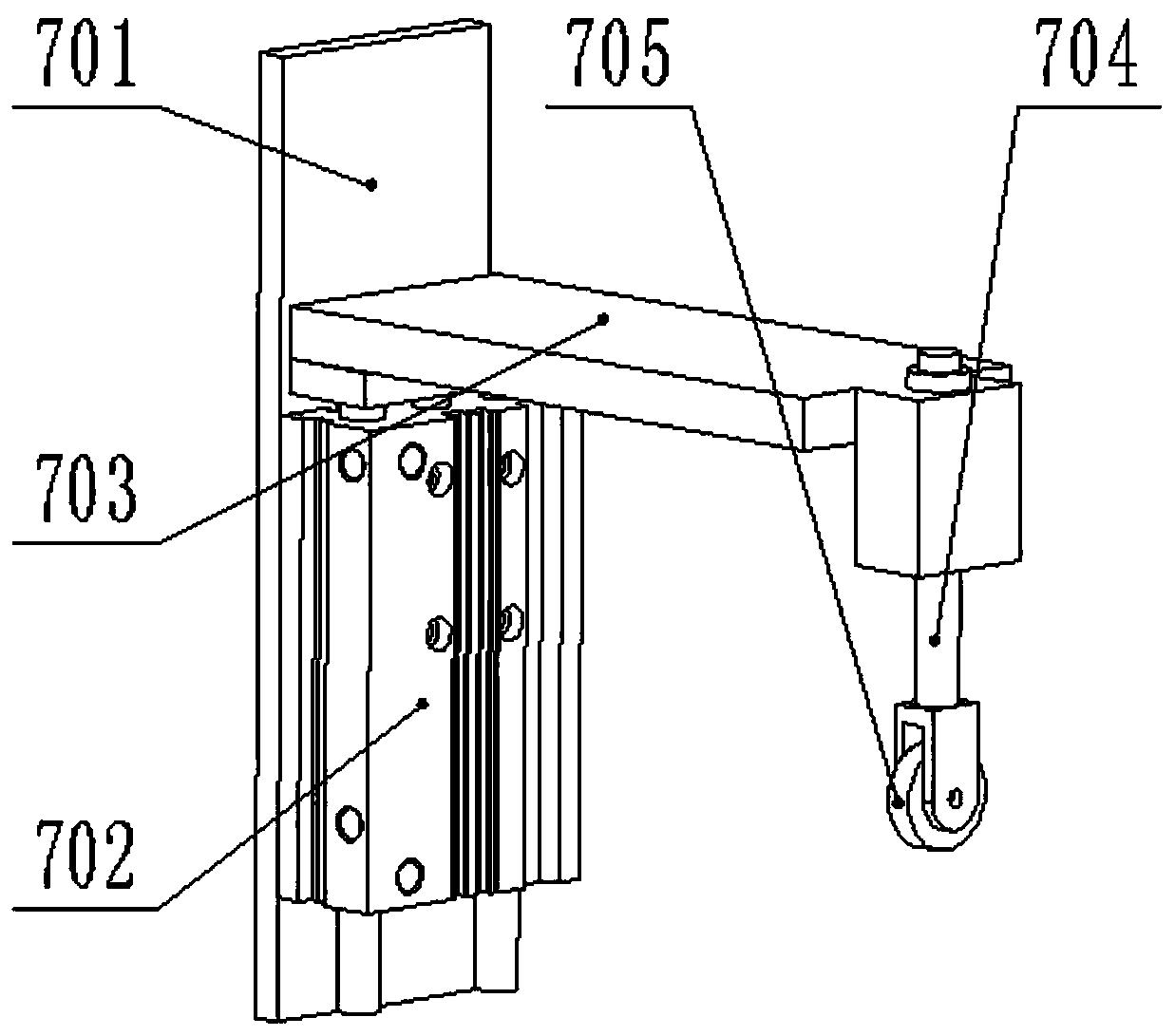

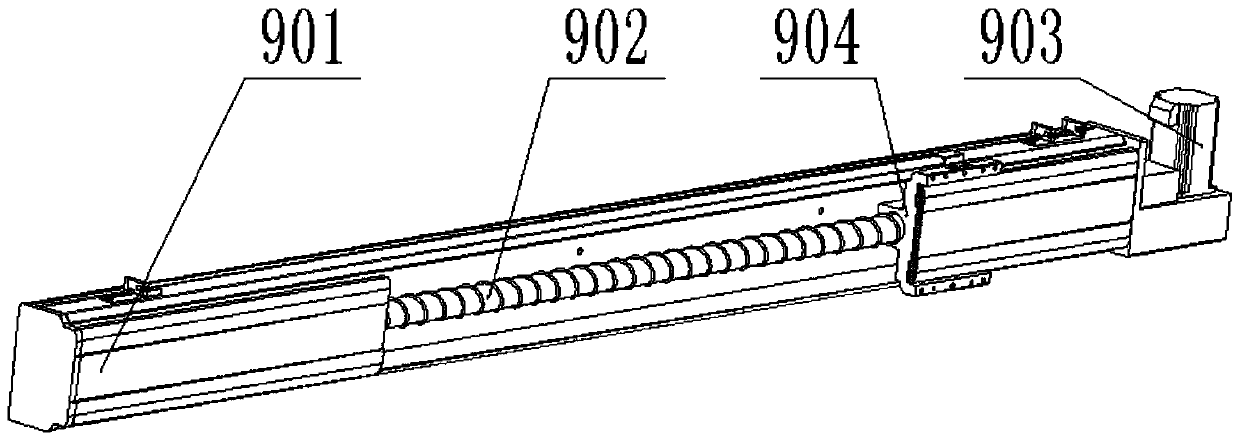

[0024] Such as Figure 1-4 The electrical safety test follow-up device for an air conditioner split internal unit as shown includes a workbench 1 on which a conveying path 2 is provided, and two sides of the conveying path 2 at one end of the workbench 1 are provided with mutual Cooperating centering device 3, through the centering device 3, the air conditioner split internal unit is positioned, and the side of the conveying path 2 is provided with a detection follow-up device, and the detection follow-up device is matched with the conveying path 2 The detection follow-up device includes a fixed bracket 4 located on the upper side of the workbench 1, and the side of the fixed bracket 4 away from the conveying path 2 is fixedly installed with a control box 5, and the fixed bracket 4 is close to the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com