Device for cleaning and recycling oil stains on water surface

A recovery device and oil pollution technology on the water surface, which is applied in the cleaning of open water surfaces, water conservancy projects, general water supply conservation, etc., can solve the problems of large water content, low efficiency, and difficult treatment in the recovery of oil pollution, and achieve automatic separation and pollution Effect of risk reduction, process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

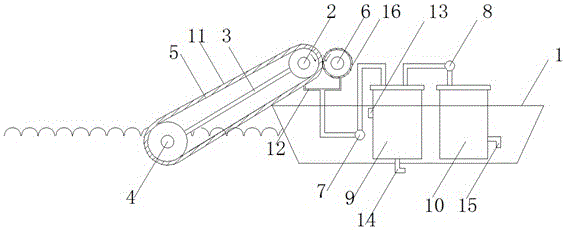

[0019] Such as figure 1 As shown, a water surface oil pollution removal and recovery device includes a hull 1, an upper transmission wheel 2 fixed on the hull 1, a cardan shaft 3, a lower transmission wheel 4, a conveyor belt 5, and a squeeze roller 6 in contact with the upper transmission wheel 2. , the first oil pump 7, the second oil pump 8 and the oil-water separation tank 9 and the oil storage tank 10 arranged on the hull 1, the upper transmission wheel 2 is powered by the engine, and the upper transmission wheel 2 is connected to the lower transmission wheel through the cardan shaft 3 4. The transmission belt is respectively surrounded with the upper transmission wheel 2 and the lower transmission wheel 4 to form a closed ring, the transmission belt 5 is equipped with a wool oil-absorbing felt 11, and the extrusion roller 6 contains a cylindrical cylinder and a shaft. It is fixedly connected with the cylinder body, the inside of the cylinder body is a hollow structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com