Metal sheet separation device based on magnetic field

A metal sheet and separation device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easily damaged metal sheets, large volume, and high energy consumption, and achieves less error-prone, small size, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

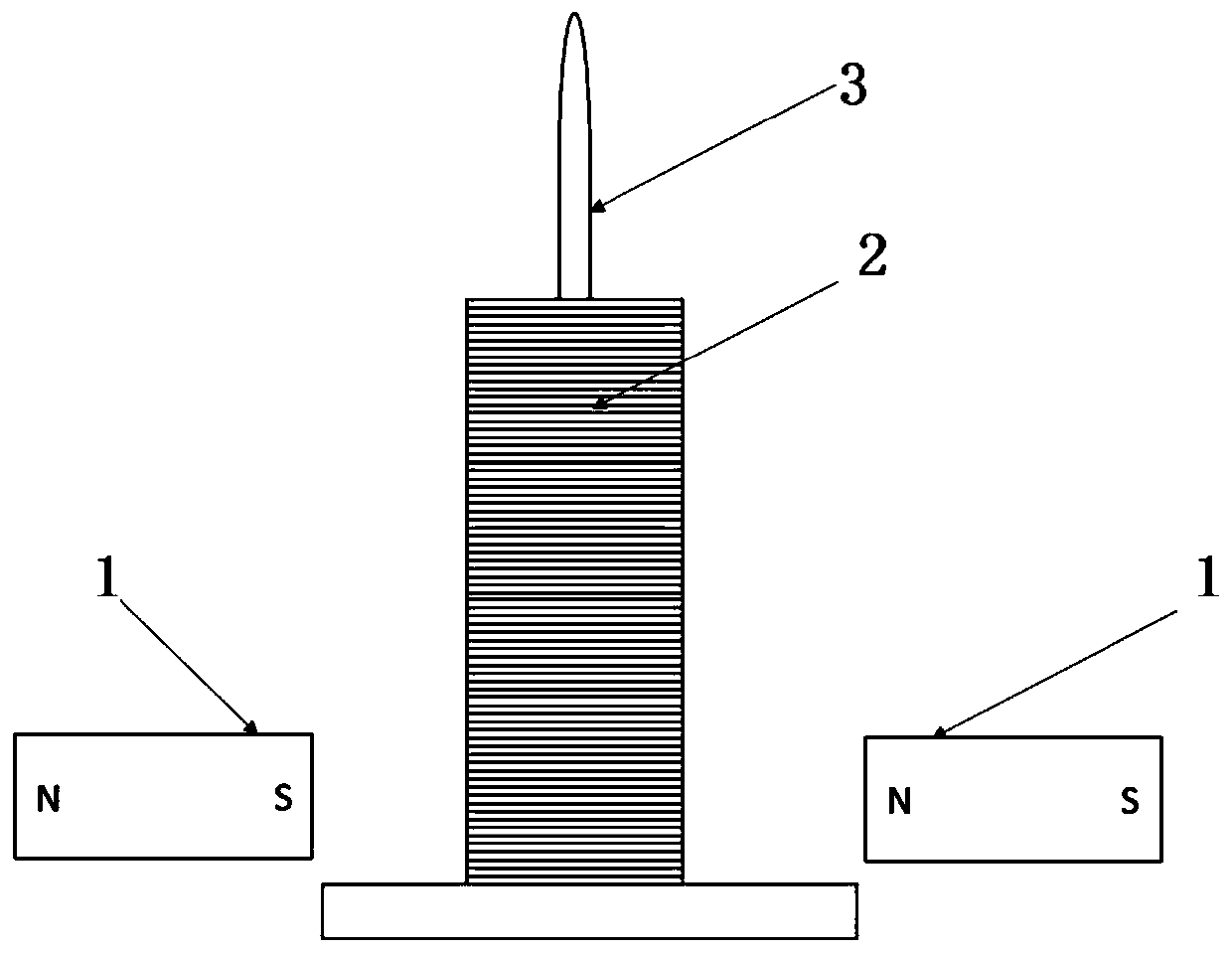

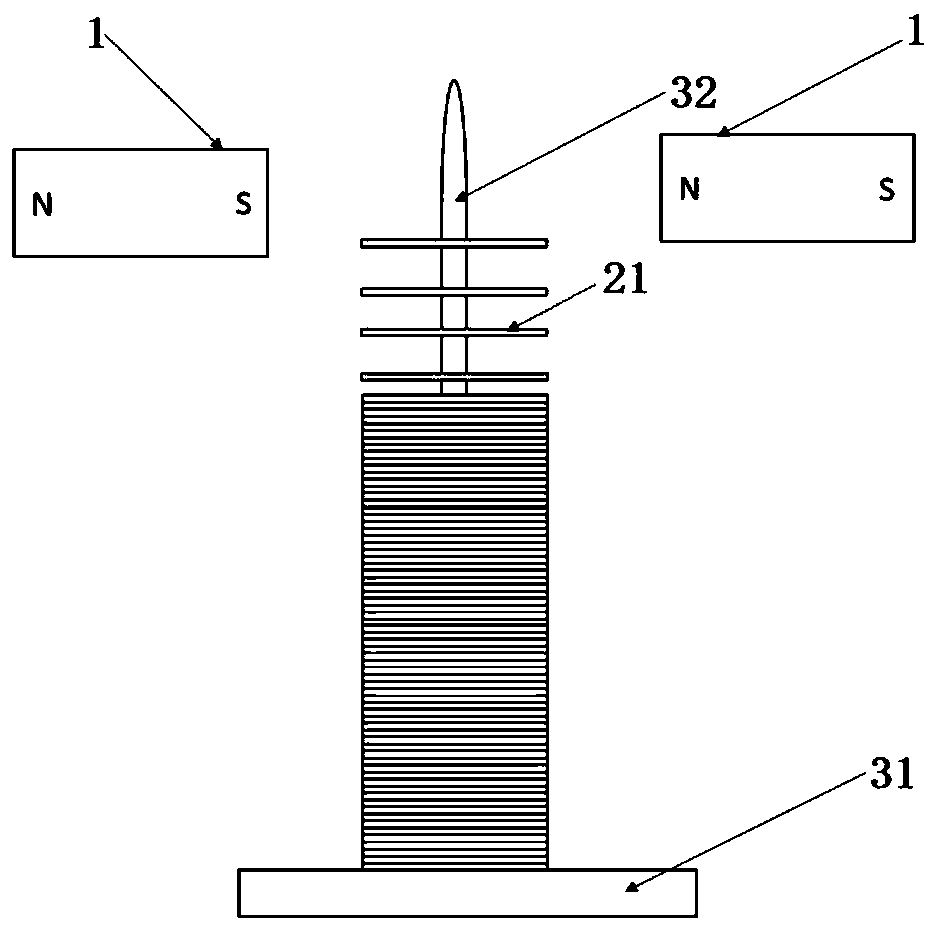

[0043] In this embodiment, a metal flake separation device based on a magnetic field, such as figure 1 As shown, it includes a sheet stacking support 3 and two magnetic field generating units 1; the sheet stacking support 3 includes a stacking platform 31 and a stacking mandrel 32; the stacking mandrel 32 is vertically installed on the stacking platform 31, and a plurality of metal sheets 21 to be separated The superimposed set is placed on the stacking mandrel 32 to form a sheet stack 2; two magnetic field generating units 1 are respectively located on both sides of the sheet stack 2, and each generates a magnetic field; the magnetic poles of the two magnetic fields near the end of the sheet stack 2 are opposite; The magnetic field generating unit 1 is any device that can generate a magnetic field. In this embodiment, it is a permanent magnet. The permanent magnet is the simplest and most convenient, and it can also be an electromagnet.

[0044] When the two magnetic field ge...

Embodiment 2

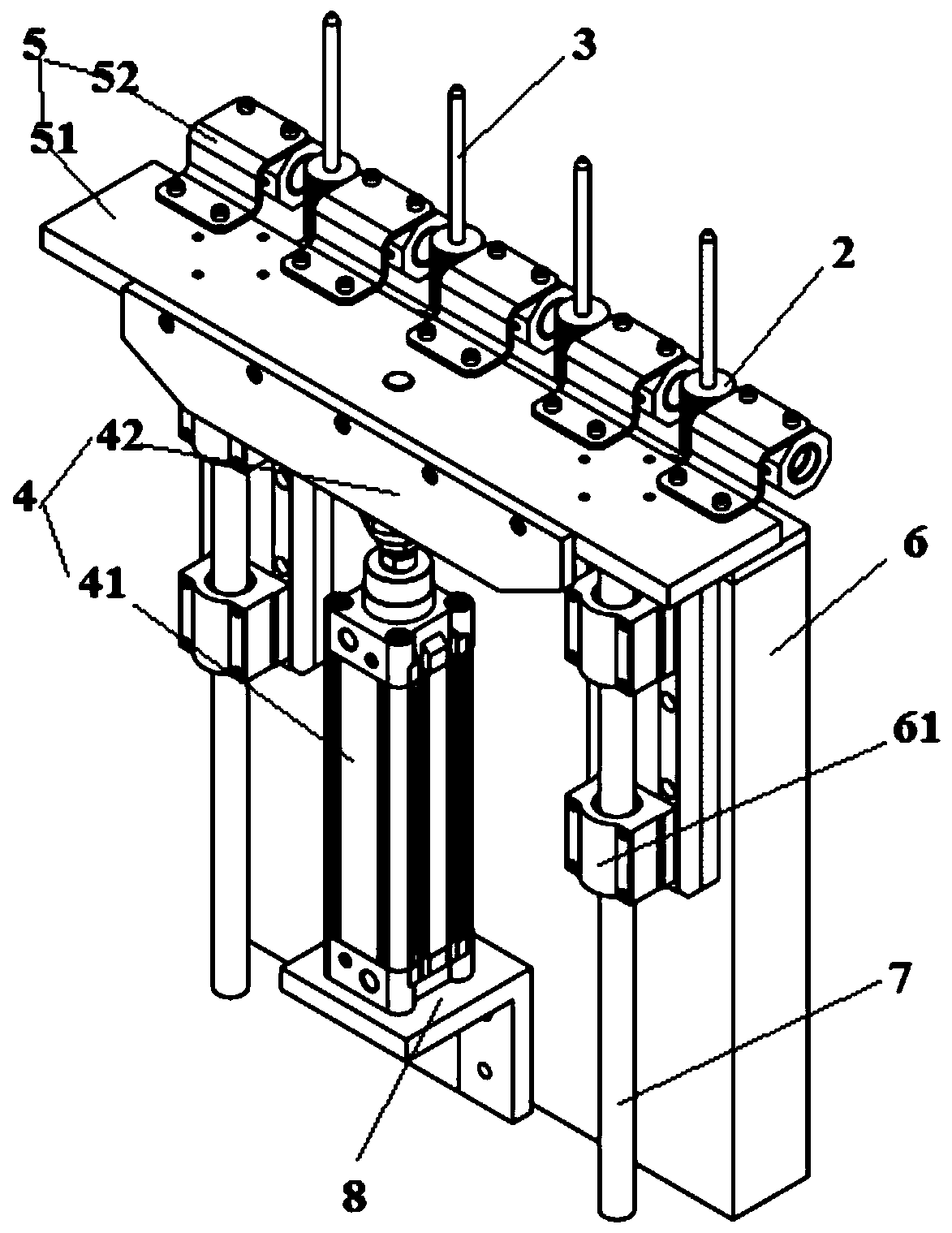

[0046] This example image 3 As shown, several metal flake separating devices as in embodiment 1 are included;

[0047] Also includes a lift unit 4 and a magnet connection assembly 5; the lift unit 4 includes a drive cylinder 41 and a mounting base 42; the drive cylinder 41 is vertically installed on the drive cylinder mounting base 8, and its output end is vertically upward; the mounting base 42 is installed on the drive The top of the output end of the cylinder 41; the magnet connection assembly 5 includes a connecting plate 51 and a plurality of connecting pieces 52; one side of the connecting plate 51 is fixedly installed on the mounting base 42, and a plurality of connecting pieces 52 are evenly arranged along its length direction on the other side The connecting piece 52 is a Z-shaped connecting piece, and can also be an S-shaped connecting piece or an L-shaped connecting piece; one end of the connecting piece 52 is fixedly connected with the connecting plate 51, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com