Ovality detection device and detection method

A detection device and ellipticity technology, which is applied in the field of mechanical processing, can solve problems such as affecting the light transmission effect, inaccurate detection results, and inability to work, and achieve the effects of controllable and adjustable accuracy, convenient operation, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]Embodiment 1. An ellipticity detection device

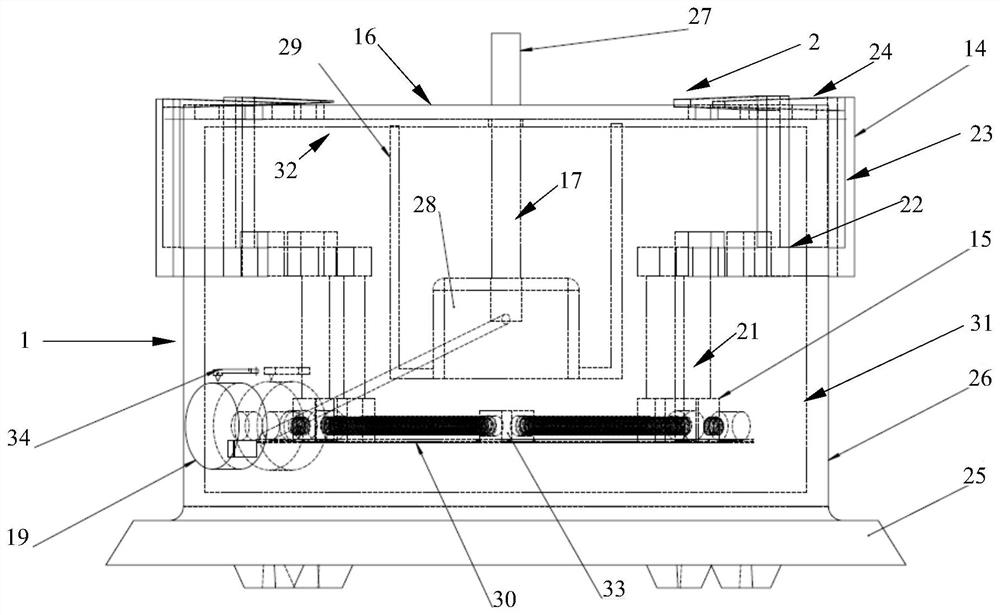

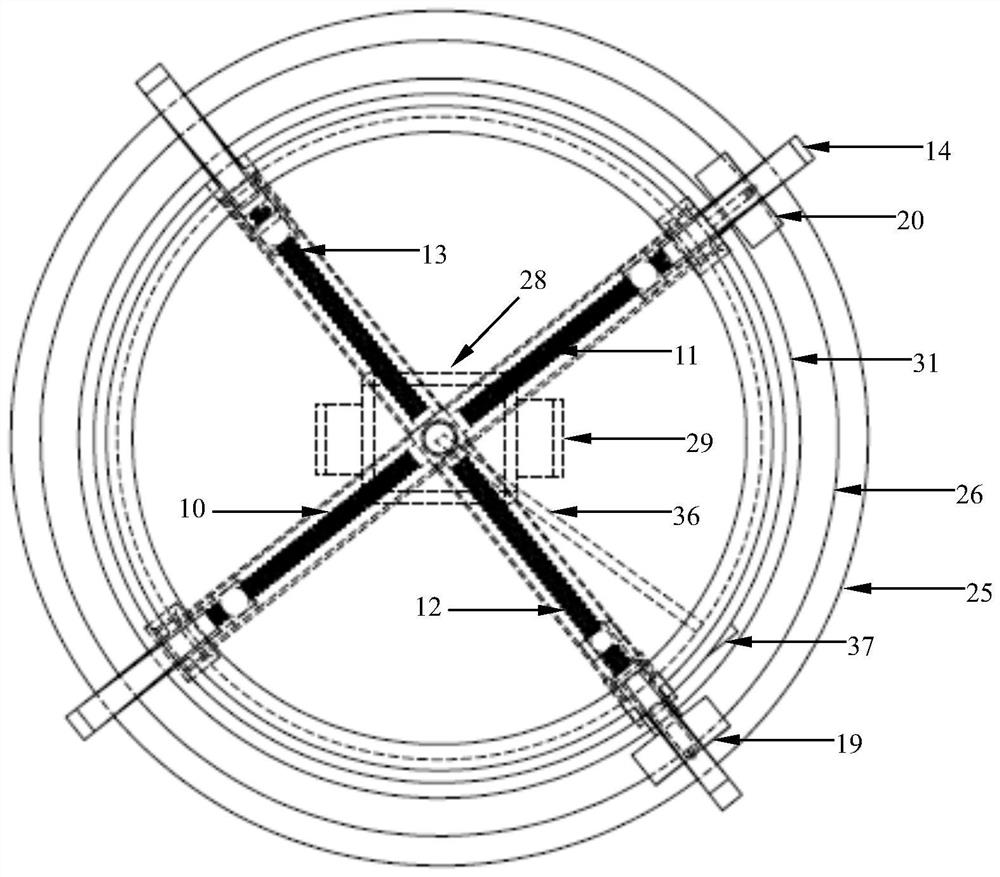

[0049]Such asfigure 1 withfigure 2 As shown, this embodiment provides an ellipticity detection device, including: a frame 1, a rotating platform 16, a probe assembly, and a control assembly,

[0050]The frame 1 includes a base 25 and a cylindrical shell fixed above the base 25. The shell includes two layers, an outer shell 26 and an inner shell 31. The top of the outer shell 26 has no bottom, and the top of the inner shell 31 is provided with Upper bottom 32,

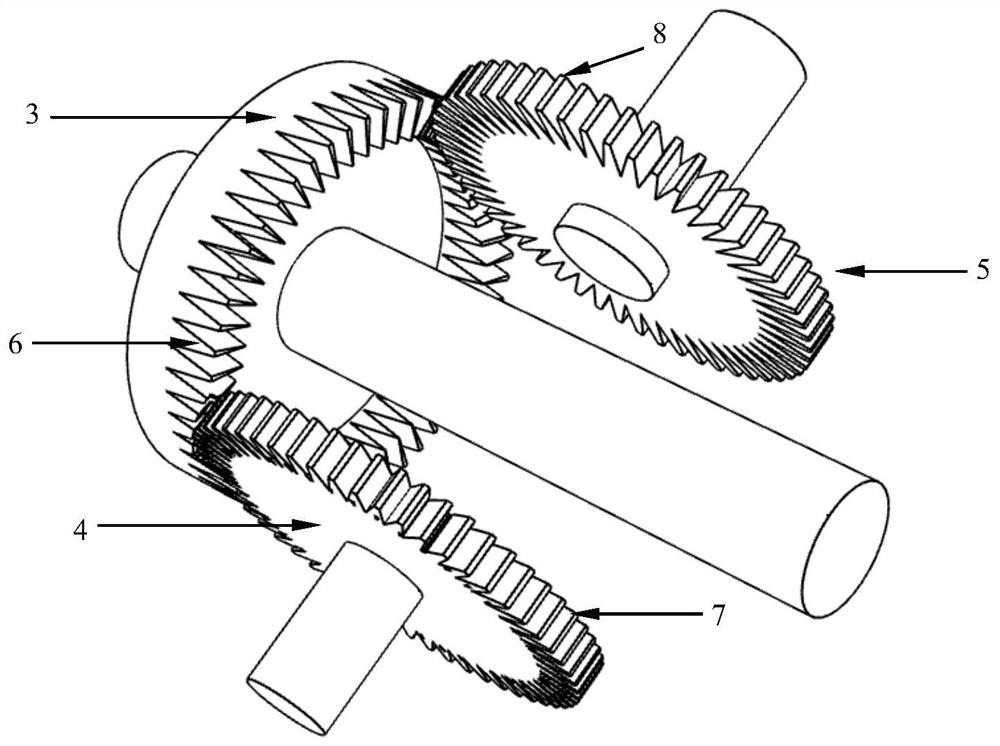

[0051]The rotating platform 16 is set above the frame 1 and can rotate in both directions, such asfigure 1 Shown is located directly above the upper base 32, close to each other in parallel but not in contact with the upper base 32. The rotating platform 16 is circular and horizontally arranged for placing the object to be tested. The lower center of the rotating platform 16 is connected to the upper end of the rotating shaft 17. It rotates smoothly with the axial rotation of the s...

Embodiment 2

[0069]Embodiment 2. A method for detecting ellipticity

[0070]Use the ellipticity detection device of embodiment 1, and the method includes:

[0071]S1. Use a fixed component (ie, probe assembly) to fix the object to be measured in a plane a (such as the surface where the upper surface of the rotating platform 16 is located), and the fixed position is located at the four points on the outer or inner edge of the object to be measured , The four points are located on a circle b of the plane a where the outer or inner edge of the object to be measured is located;

[0072]S2, at a fixed position, move the fixed part away from the outer edge or inner edge of the object to be measured by a certain distance c along the radial direction of the inner circle b of the plane a;

[0073]S3. Make the object to be measured make two mutually opposite axial rotations in plane a, and if the fixed part jams the outer or inner edge of the object to be measured during each axial rotation, record each time it is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com