Static indentation damage prefabrication testing machine for composite material structures

A composite material and static indentation technology, which is applied in the direction of testing the strength of materials by applying repetitive force/pulsation force, and testing the strength of materials by applying stable tension/pressure, which can solve problems such as large structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

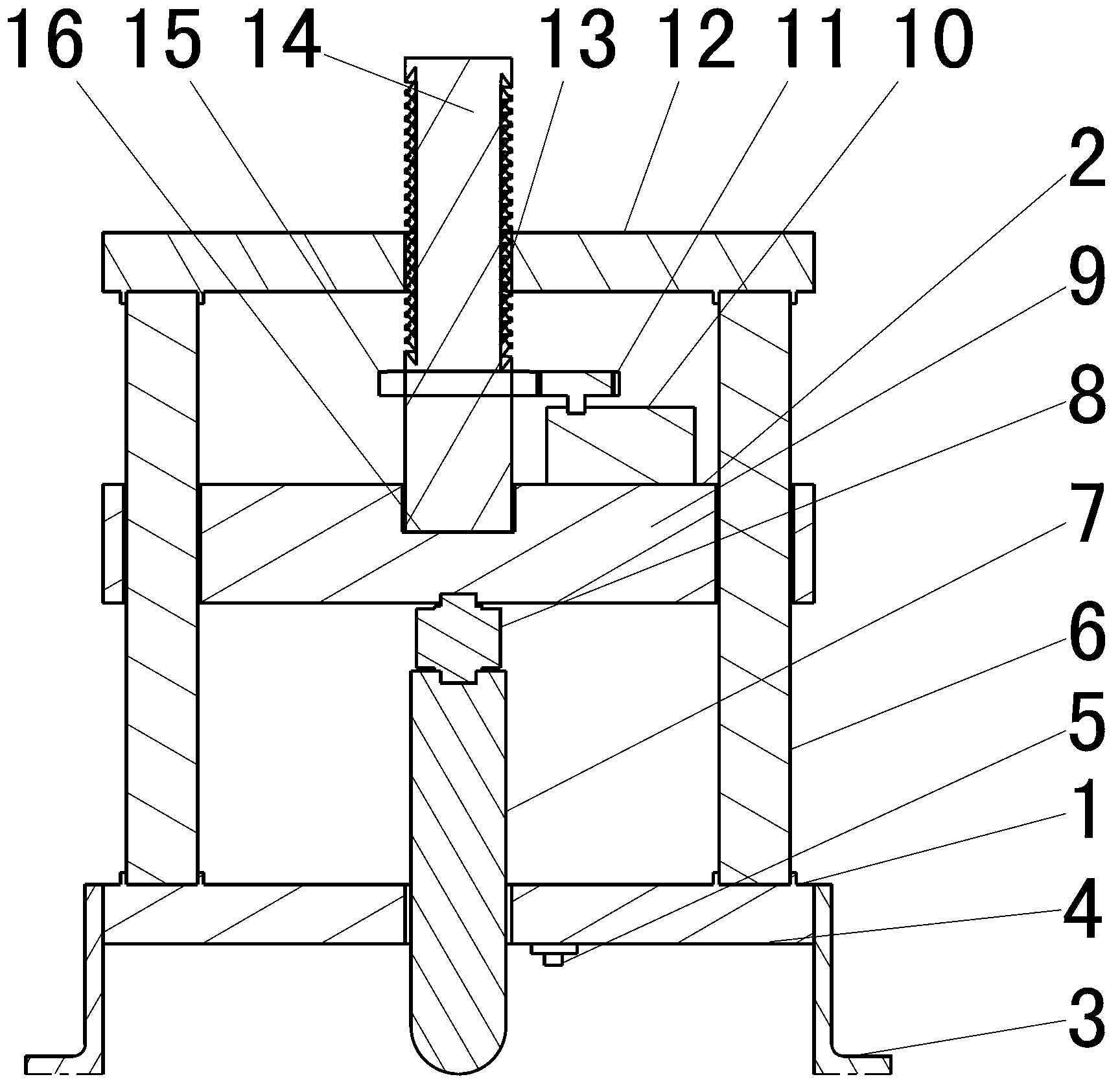

[0030] Such as figure 1 As shown, a composite material structure static indentation damage prefabrication test machine includes a support assembly 1, an indenter 7, an indenter feed assembly 2 and a measurement and control assembly, the indenter feed assembly 2 is connected to the support assembly 1, And it is connected with the indenter 7 in transmission, the measurement and control assembly is connected with the indenter feeding assembly 2, and the indenter 7 is aimed at the test piece.

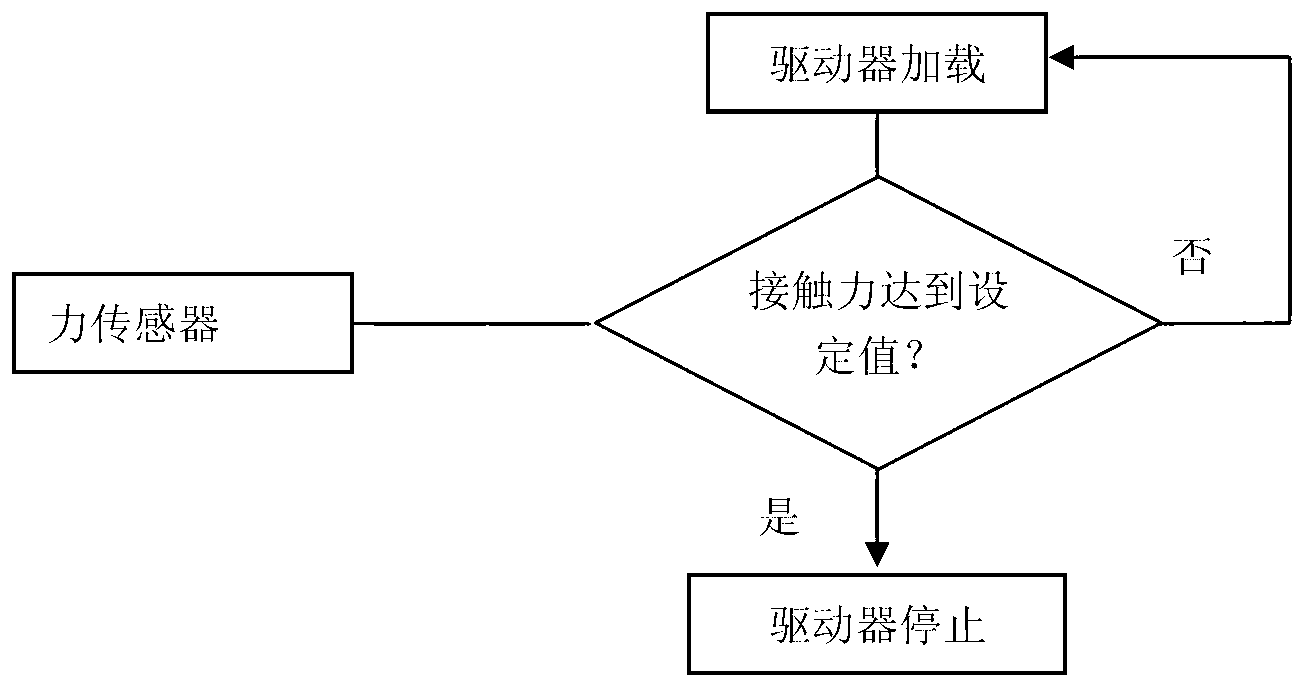

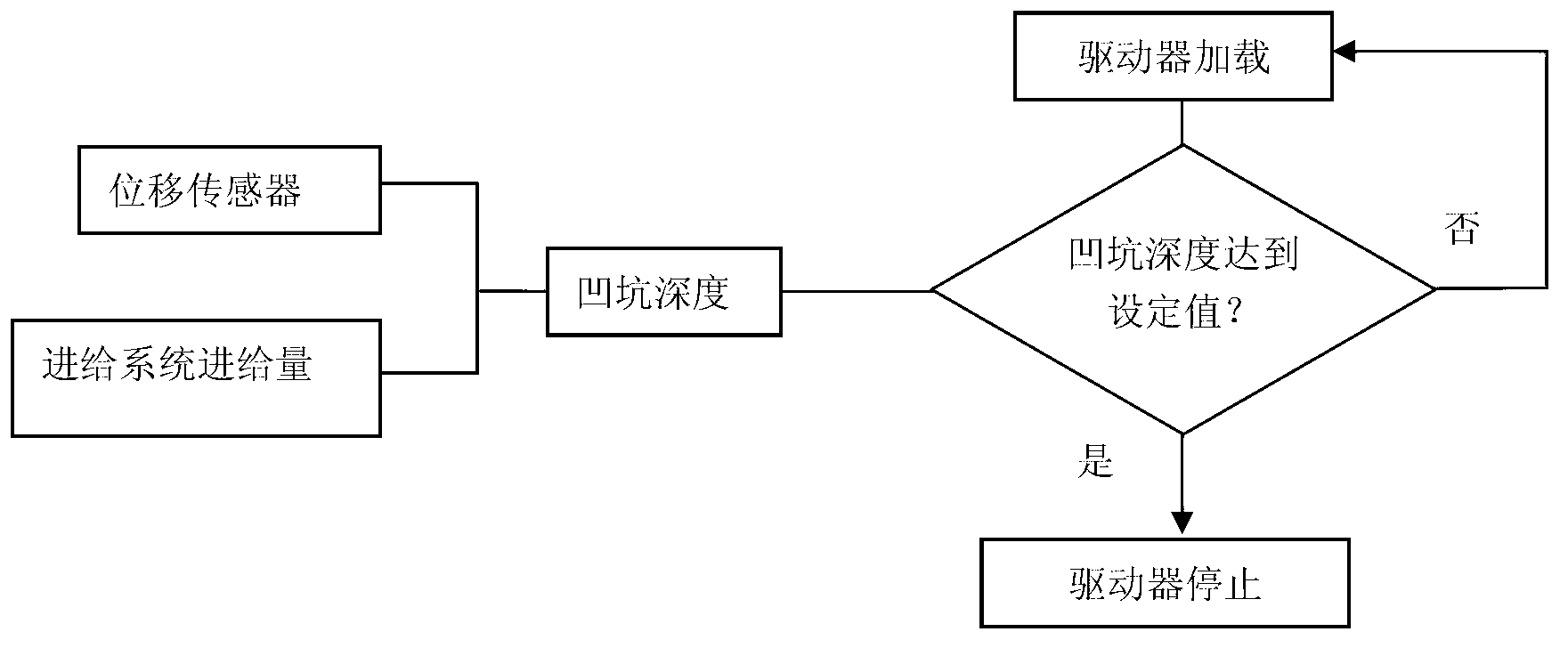

[0031] The support assembly 1 includes a foot 3 , a lower beam 4 , a column 6 and an upper beam 12 , and the lower beam 4 is fixed on the foot 3 and connected to the upper beam 12 through a column 6 . The indenter feeding assembly 2 includes a displacement sensor 5, a force sensor 8, a lifting beam 9, a driver 10 and a screw 14. The displacement sensor 5 is fixed on the lower beam 4, and is used to measure the surface of the test piece relative to the lower beam. 4, the force sensor 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com