Drilling pressure pushing pressurizer

A pressure-on-drilling and pressure-relief hole technology, which is applied to drill pipes, drill pipes, earthwork drilling, etc., can solve the problems of difficult to control the drilling pressure, drill bit chipping, small drilling pressure, etc., and achieves convenient maintenance and installation, and reliable Effect of torque transmission and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

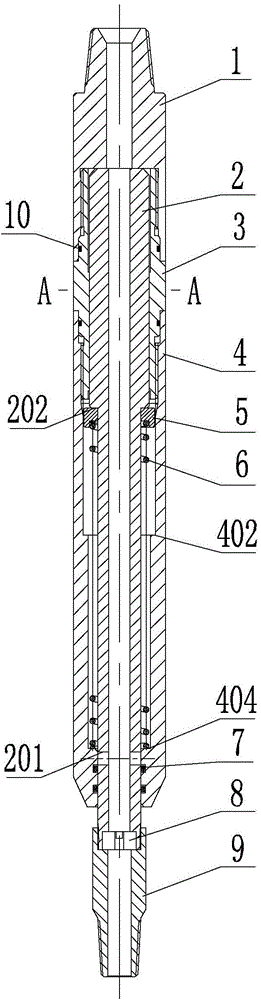

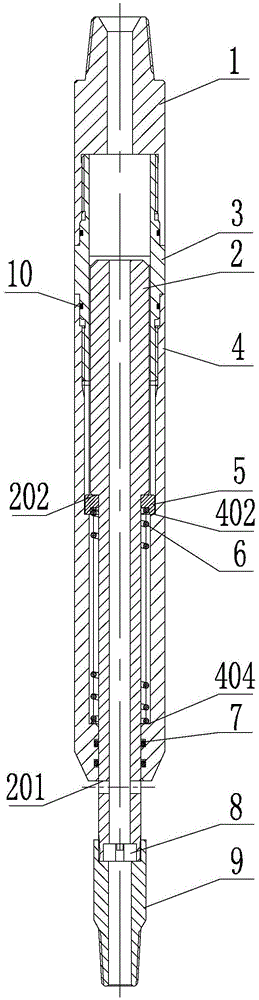

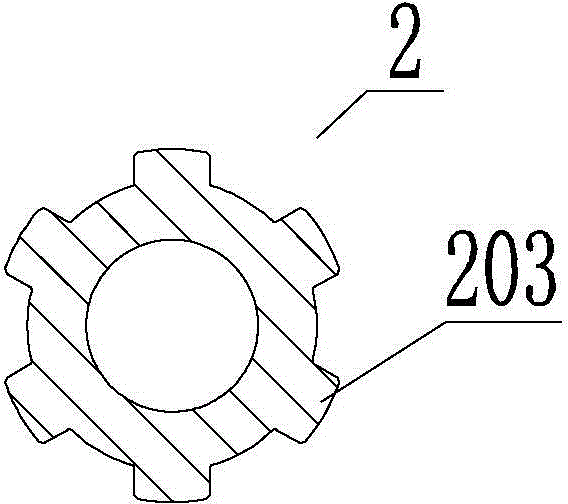

[0032] see figure 1 As shown, the drilling weight pusher of the present invention includes an upper joint 1, a piston 2, a housing 4, a throttle ring 8 and a lower joint 9. The shell 4 is a hollow cylinder, and one end of the shell 4 is connected with one end of the upper joint 1; The end of the piston 2 away from the upper joint 1 slides downwards out of the housing 4 , the protruding end of the piston 2 and the housing 4 are in sliding and sealing fit, and the protruding end of the piston 2 is connected with one end of the lower joint 9 .

[0033] The throttling ring 8 is connected with the protruding end of the piston 2 to generate throttling pressure difference. The upper joint 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com