Interference fit part assembling and disassembling device applying ultrasonic vibration and using method

An interference fit and parts assembly technology, applied in the field of disassembly devices and interference fit parts assembly, can solve problems such as difficulty in disassembly of interference fit parts, scratches on the surface of parts mating, affecting assembly quality, etc. The effect of reducing injury and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

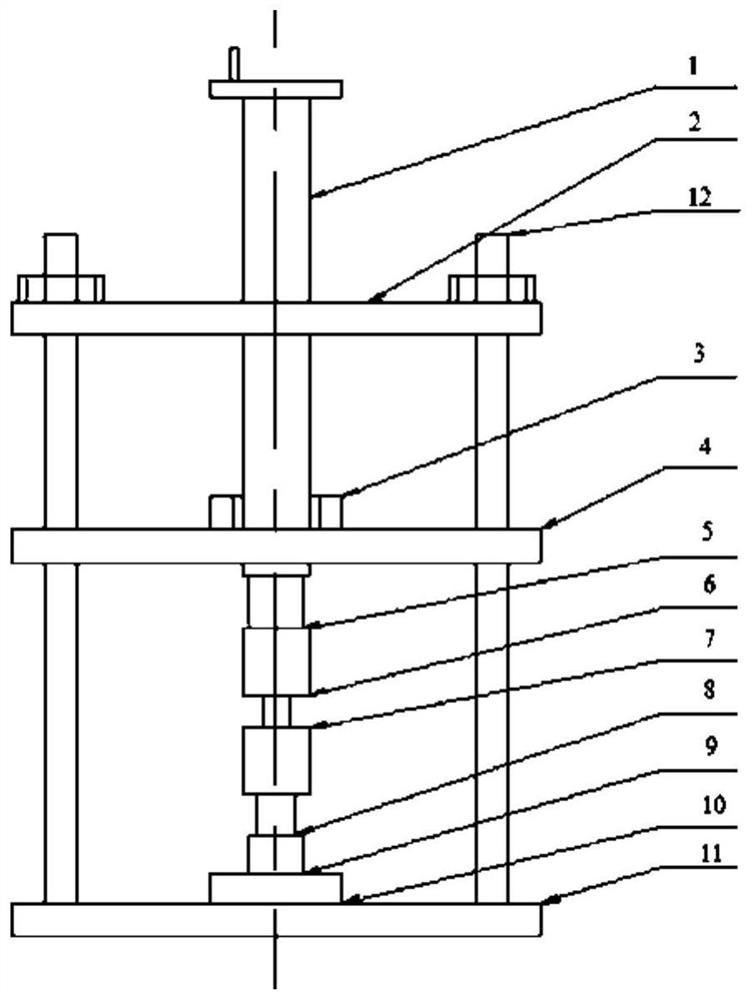

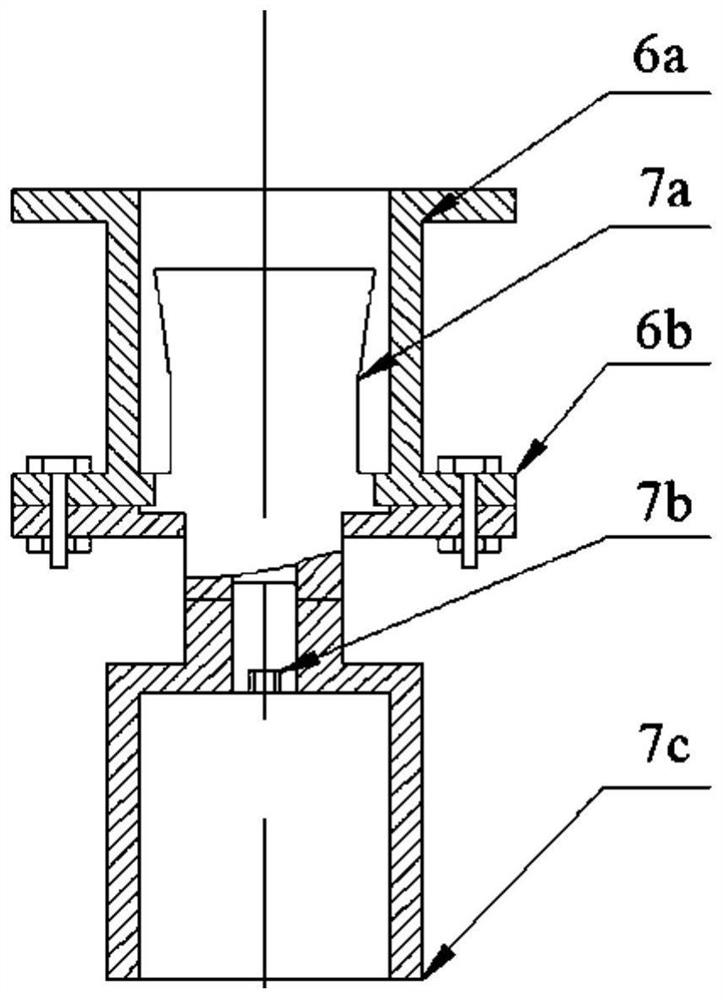

[0021] An interference fit parts assembly and disassembly device using ultrasonic vibration; such as Figure 1-4 Shown; comprise press 1, ultrasonic generating device 5, sleeve mechanism 6, vibrating mechanism 7; Described press 1 is the mechanical press 1 with lifting thread, and described press 1 comprises shaft, press The axis of 1 is a threaded shaft; the threaded shaft runs through the threaded hole in the center of the top beam 2 and the middle beam 4; the threaded shaft is connected through the threaded holes provided on the top beam 2 and the middle beam 4; the middle beam 4 is arranged on the top beam 2 Below; the ultrasonic generating device 5 is arranged below the middle beam 4, the ultrasonic generating device 5 and the sleeve mechanism 6 are connected by bolts through a flange, and the sleeve mechanism 6 is composed of a sleeve 6a, a lower end cover 6b and connecting bolts The casing 6a is a cylinder with an upper flange on the upper end and a lower flange on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com