Rotor iron core of motor and small motor

A technology of rotor iron core and small motor, applied in the direction of magnetic circuit rotating parts, winding insulation shape/style/structure, magnetic circuit shape/style/structure, etc. It can prevent bending and deformation of the core piece, suppress bending and damage, and increase the joint area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

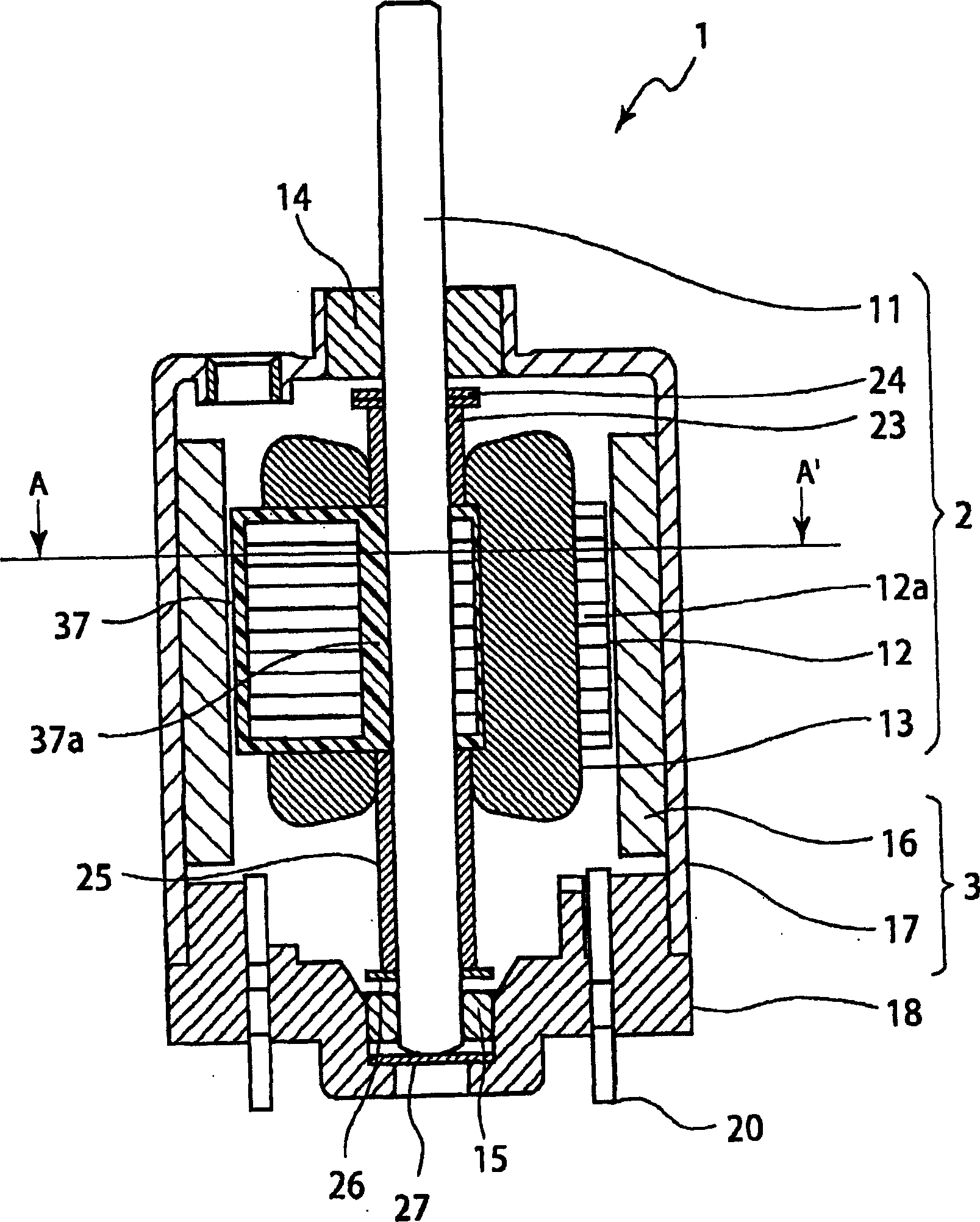

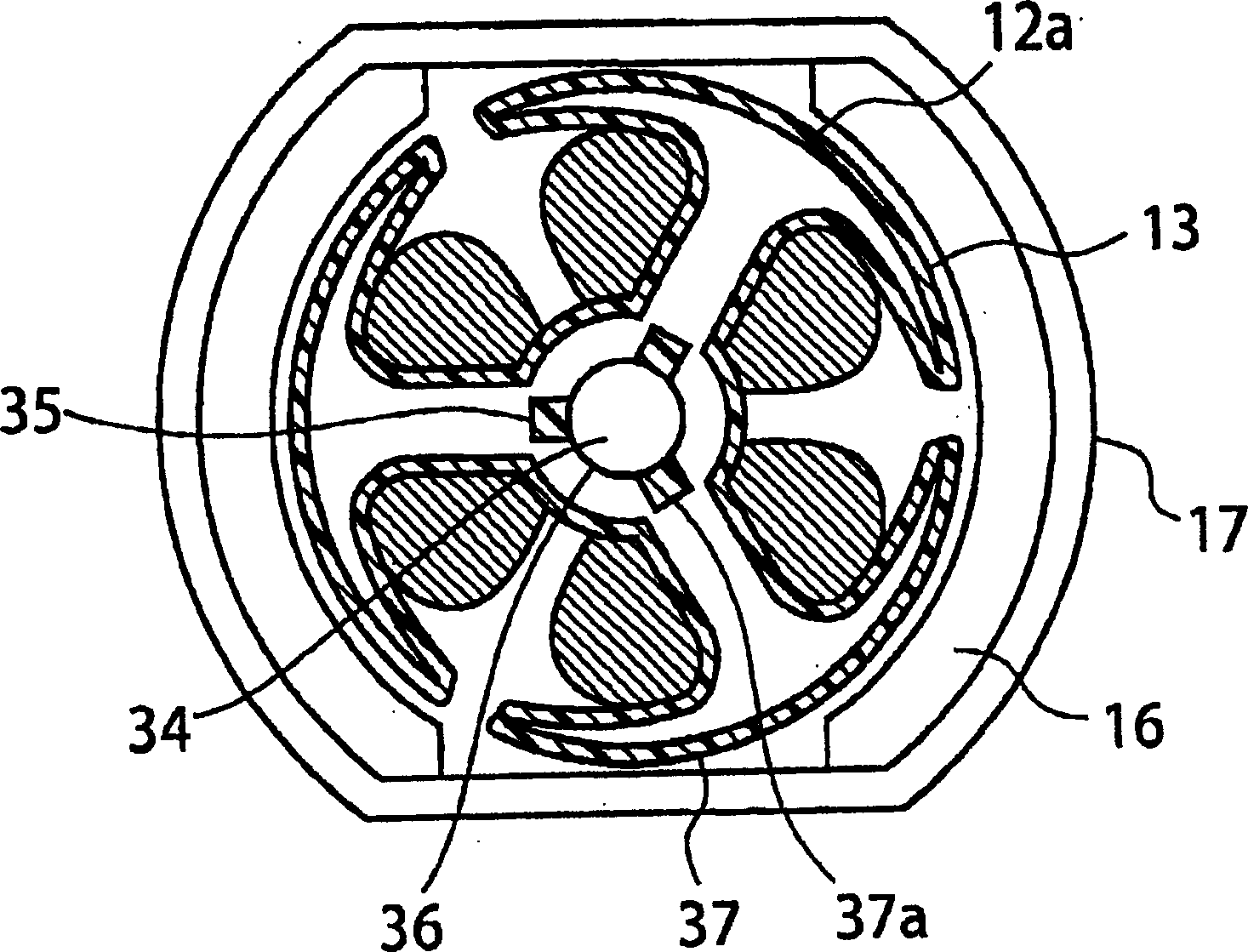

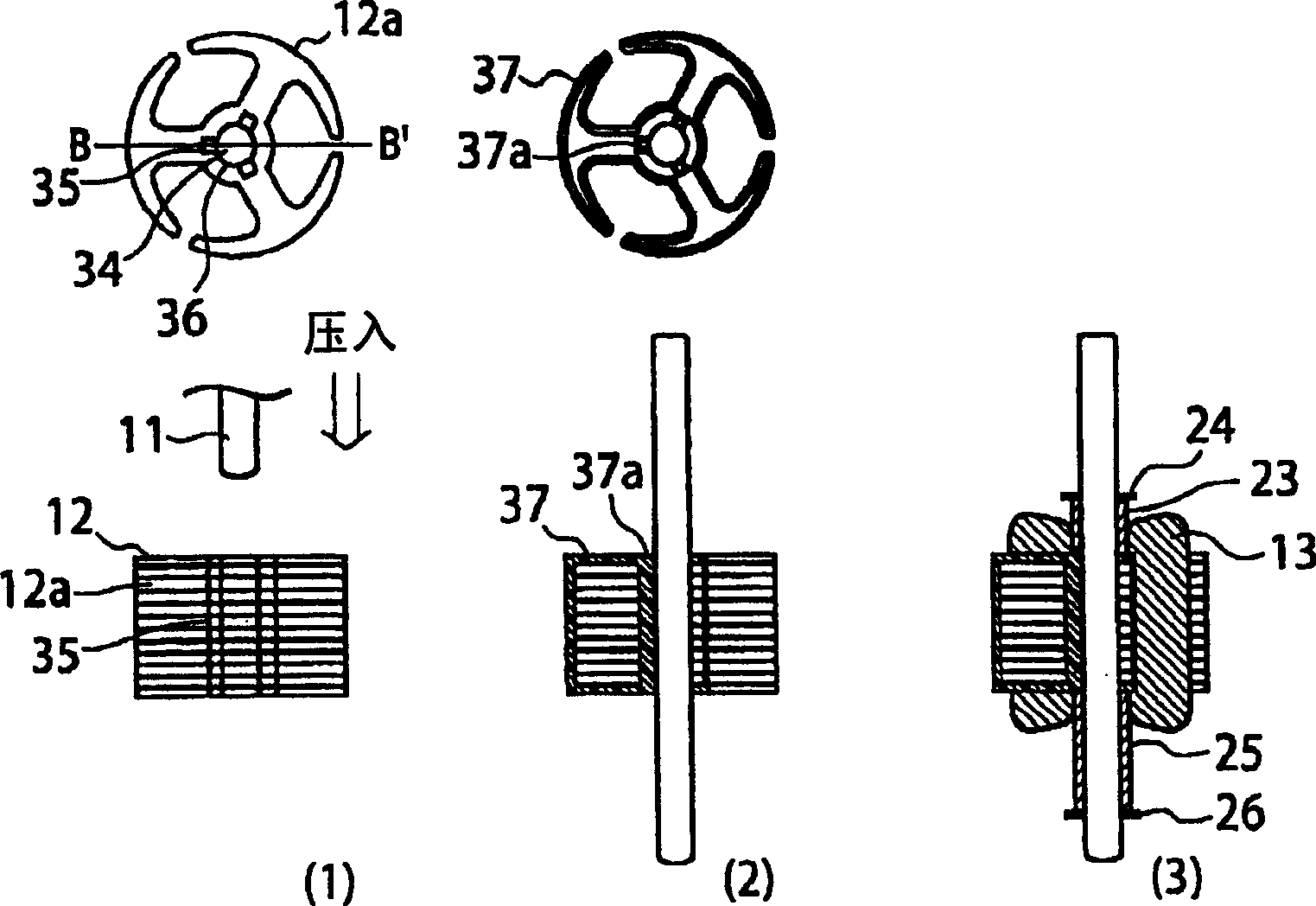

[0033] figure 1 It is a sectional view of main parts of the motor according to Embodiment 1 of the present invention. figure 2 It is seen from the vertical direction relative to the rotation axis of the motor of Example 1 figure 1 A cross-sectional view of part A-A' of . image 3 It is a diagram showing a process of forming the rotor part by pressing the cores stacked on the rotating shaft, forming a resin film on the gap between the core pieces, and winding a winding on the rotor core after joining the rotating shaft and the core. . In addition, the term "rotor core" refers to a member in which a rotating shaft is press-fitted into the core and joined with a resin film in the gap, and the term "rotor coil" refers to a member in which a winding is wound on the rotor core.

[0034] figure 1In the motor 1, a winding 13 is wound on a core 12 formed by laminated core pieces 12a, and a rotor core in which a rotating shaft 11 made of stainless steel is press-fitted, and a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com