Linear ball bearing

By adopting a basically sleeve-type cage and support plate structure in the linear ball bearing, the problems of high radial structural height and high insertion force in the existing technology are solved, and low cost, high precision and high load capacity are achieved. load direction characteristic curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

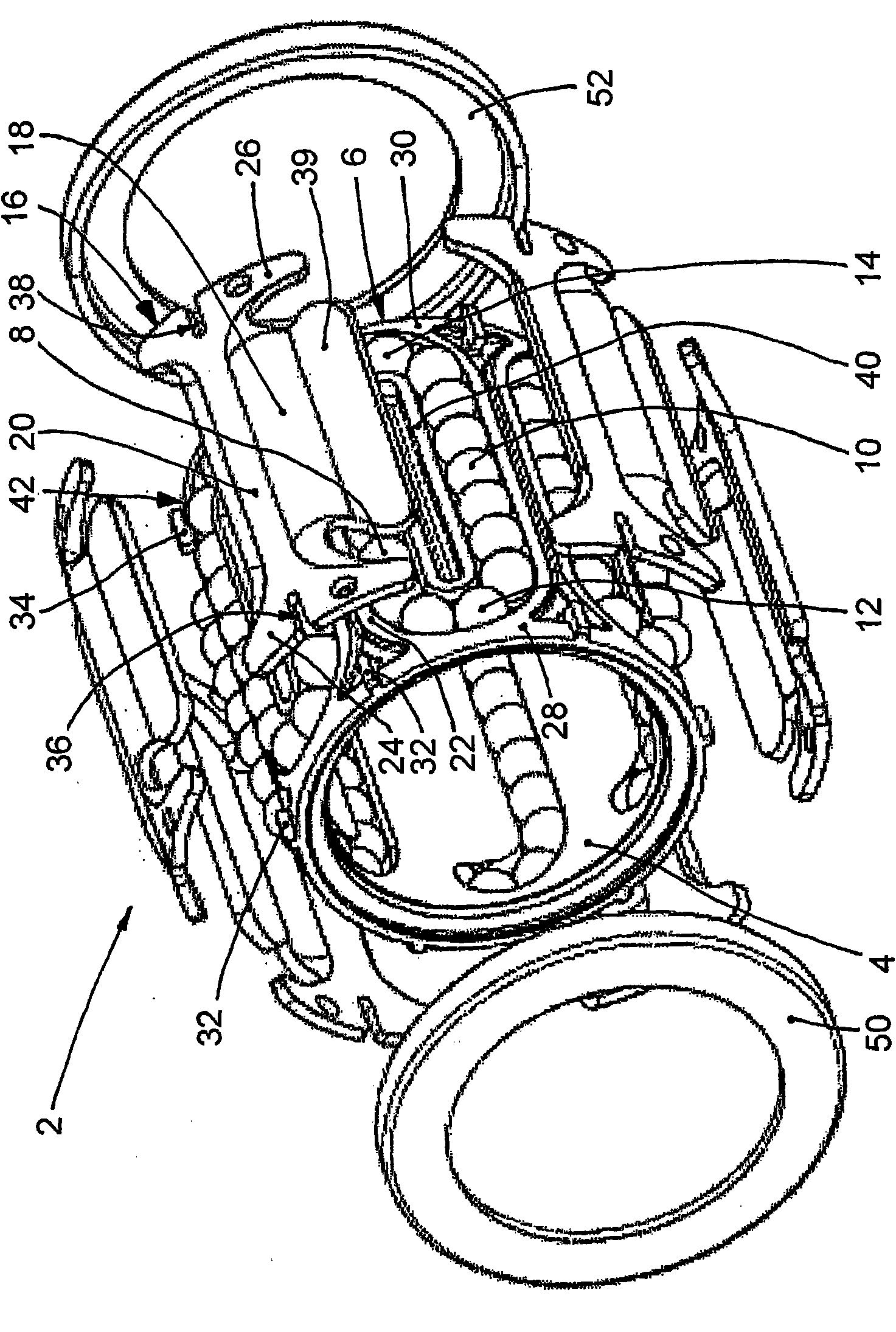

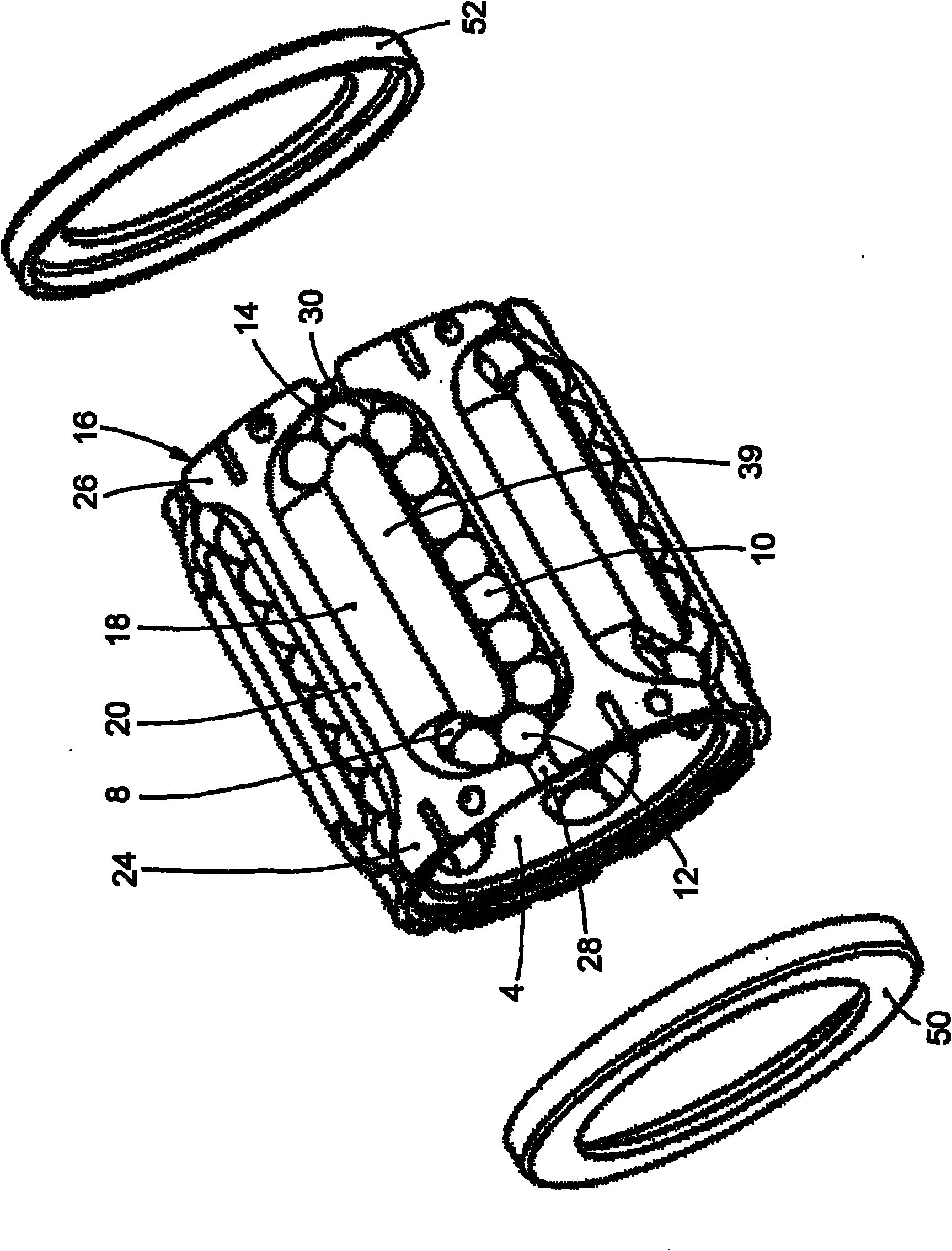

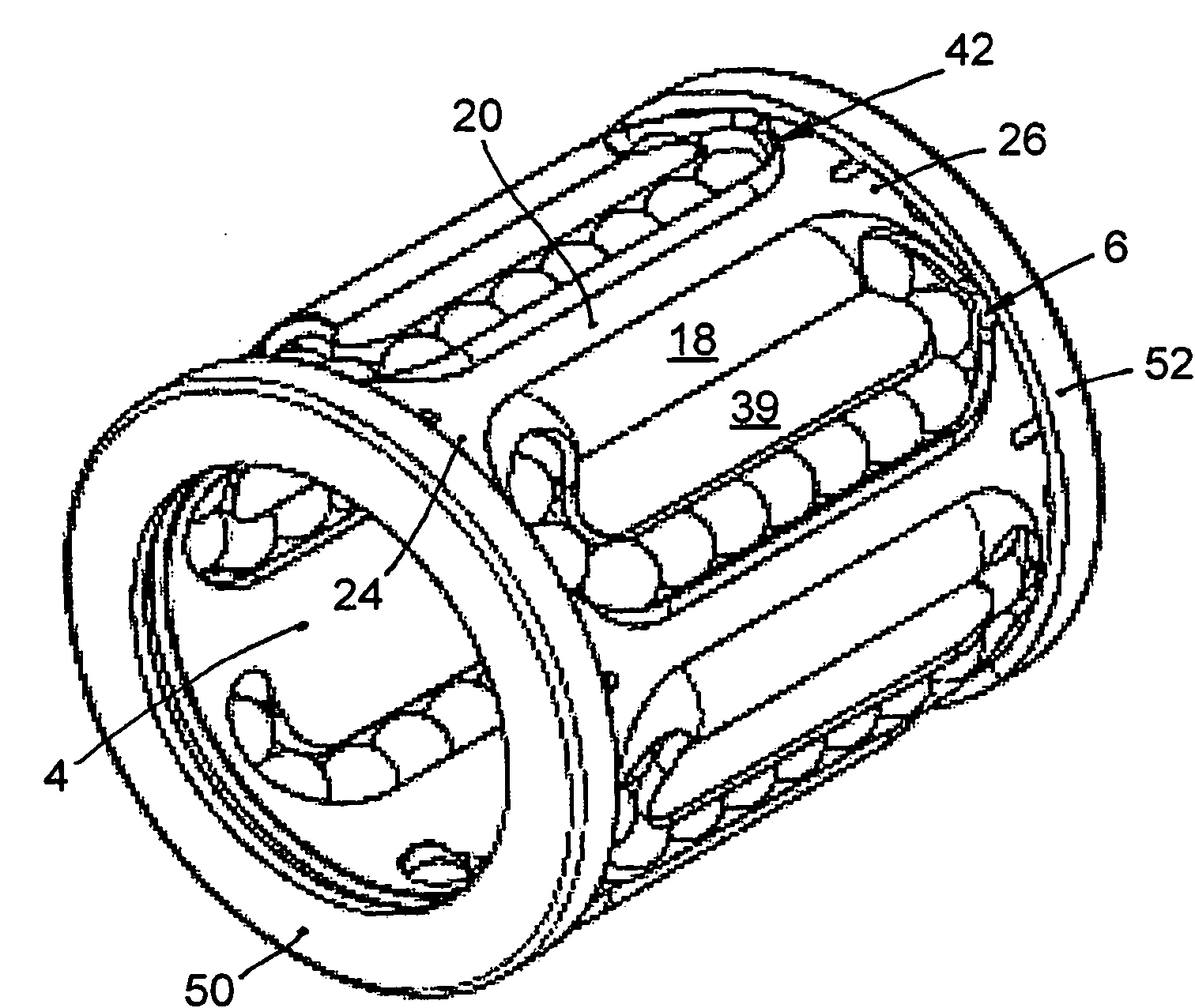

[0025] Figure 1-4 Different assembled states or views of preferred embodiments of the invention are shown.

[0026] The linear ball bearing 2 comprises a substantially sleeve-like cage 4 for accommodating a plurality (six in this embodiment) of axial ball races distributed over the circumference of the cage, wherein each ball race comprises a A first raceway open radially inwards and outwards for the bearing ball row and a radially outwardly opening second raceway for the unsupported ball row and a diversion way interconnecting the raceways of the ball rings. Such cages are known per se and therefore need not be described in detail here.

[0027] The individual ball races of the linear ball bearing 2 are constructed identically, so that the invention will be explained in more detail below with reference to a ball race 6 . The ball race 6 is formed by bearing balls 8 in a first raceway, unsupported balls 10 in a second raceway and balls 12 or 14 in a deflection track. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com