car connector

A technology for vehicle connectors and docking parts, which is applied in the direction of vehicle connectors, connections, parts of connection devices, etc., can solve problems such as difficult to realize, impact displacement of terminals, and low yield rate, so as to reduce production costs and ensure Accurate position, the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

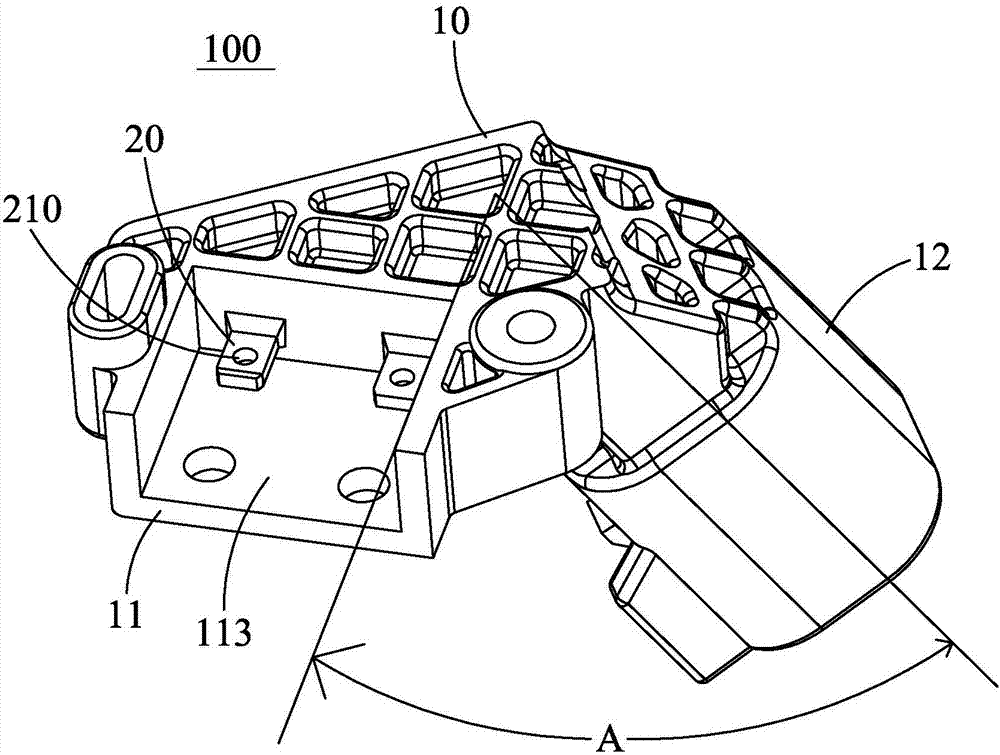

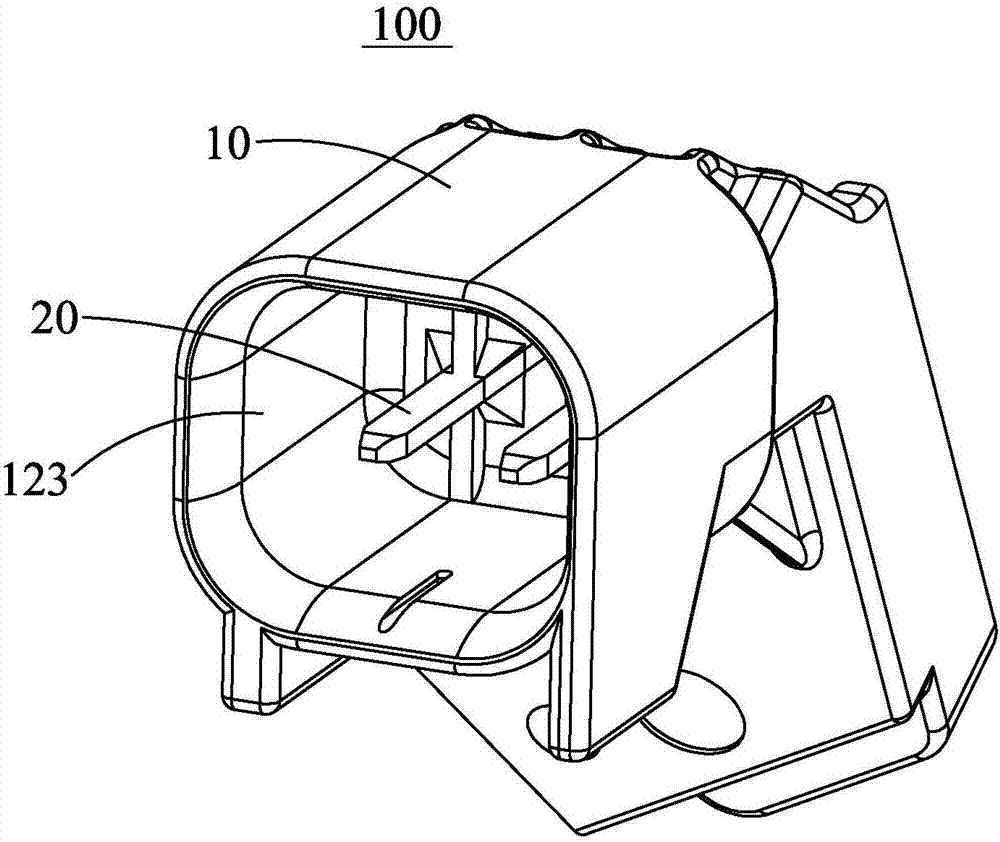

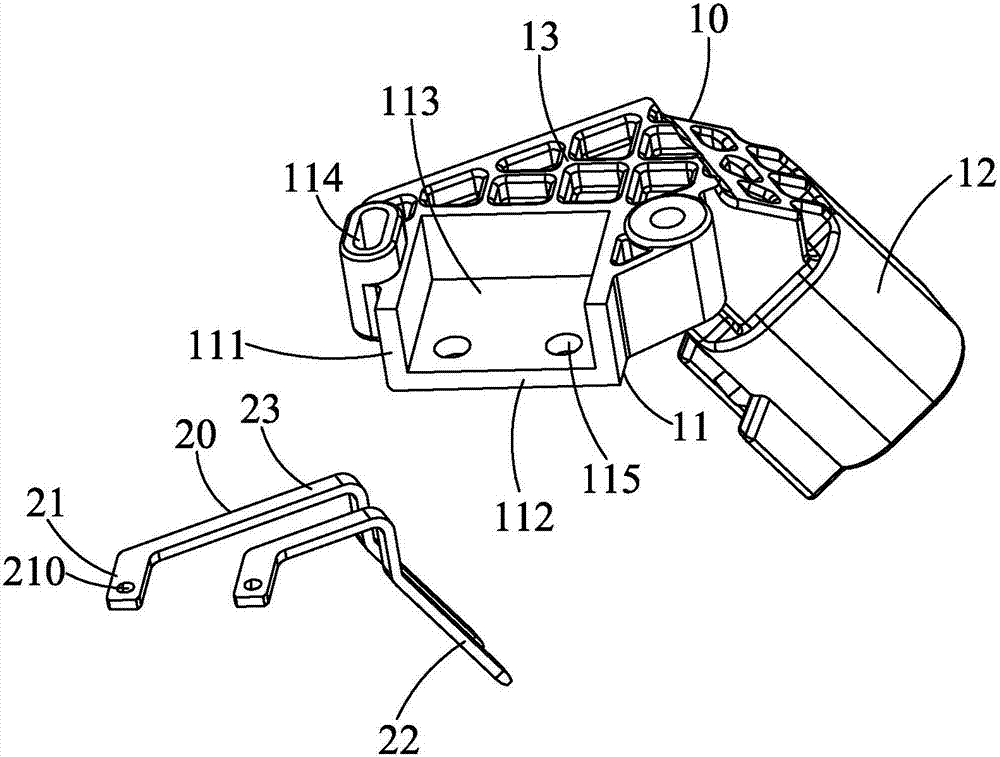

[0010] see Figure 1 to Figure 4 As shown, the vehicle connector 100 of the present invention includes an insulating shell 10 and a plurality of conductive terminals 20 inserted into the insulating shell 10 .

[0011] The insulating housing 10 includes a first docking portion 11 , a second docking portion 12 and a main body 13 connecting the first docking portion 11 and the second docking portion 12 , the first docking portion 11 is horizontally forward from the main body 13 The second butt joint portion 12 protrudes obliquely and downward from the rear end of the main body portion 13 . The angle A between the butting directions of the first abutting portion 11 and the second abutting portion 12 is less than 90 degrees.

[0012] The first docking portion 11 is U-shaped in the front-to-back direction, and includes left and right opposite side walls 111 and a bottom wall 112 connecting the two sides 111, the side walls 111 and the bottom wall 112 form a pair of docking recesses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com