Cord string branch dome

A chord-supported dome and cable-rod technology, used in roofs, building components, buildings, etc., can solve the problems of increasing the burden of supporting structures, increasing the stress of compression rods and edge ring beams, and being unable to self-adjust, so as to improve stability and performance. Effect of ultimate bearing capacity, roof stiffness improvement and restraint enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

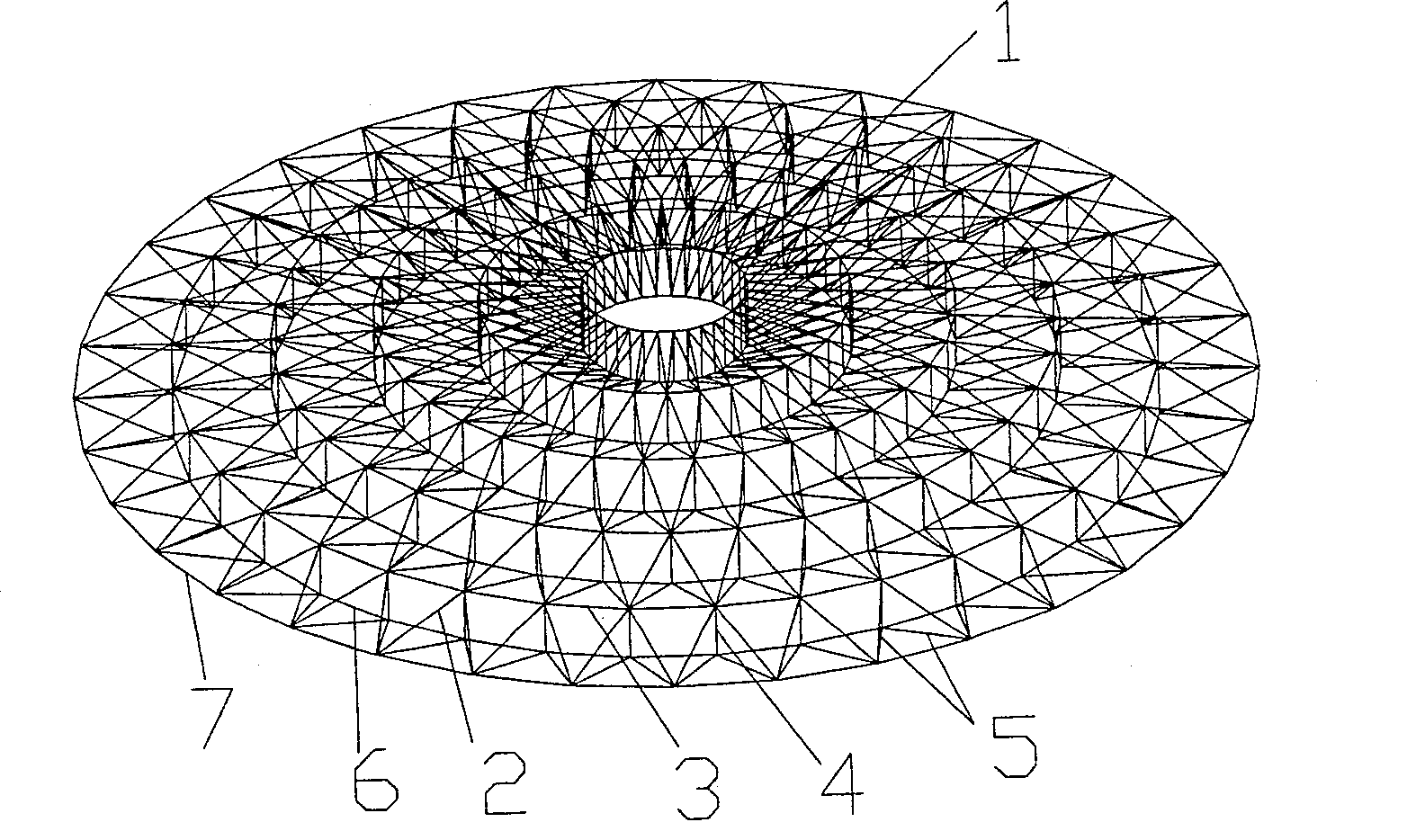

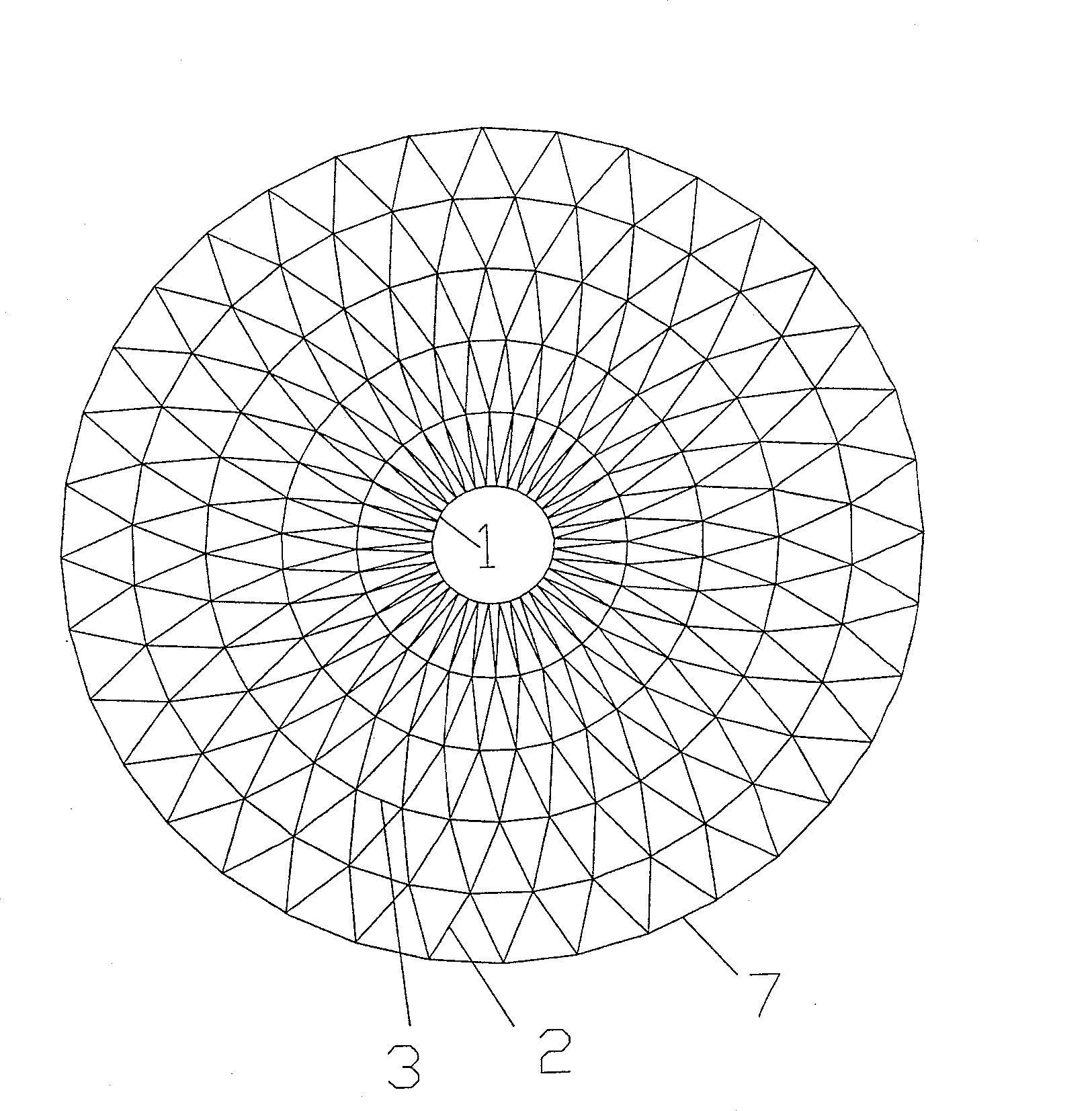

[0035] Such as figure 1 , figure 2 , Figure 4 , Image 6 As shown, this embodiment mainly includes upper and lower parts. The upper layer is composed of a central pressure ring 1, an upper radial rod 2, an upper ring cable 3 and a side ring beam 7. The upper radial rod 2 is connected with the central ring beam at the center of the dome. 1 is hinged, hinged with the side ring beam 7 at the periphery, and hinged with the upper ring cable 3 in the middle, arranged in a joint square grid, and the outline shape of the grid is circular. The lower layer is composed of the lower radial cable 5, the lower ring cable 6 and the strut 4. The upper end of the strut 4 is connected to the node of the upper layer, and the lower end is connected to the node of the lower layer; Its cross end is connected with the lower end of the strut 4, and the other two ends are respectively connected with different nodes of the upper layer. The lower hoop cable 6 is closed and arranged along the hoop ...

Embodiment 2

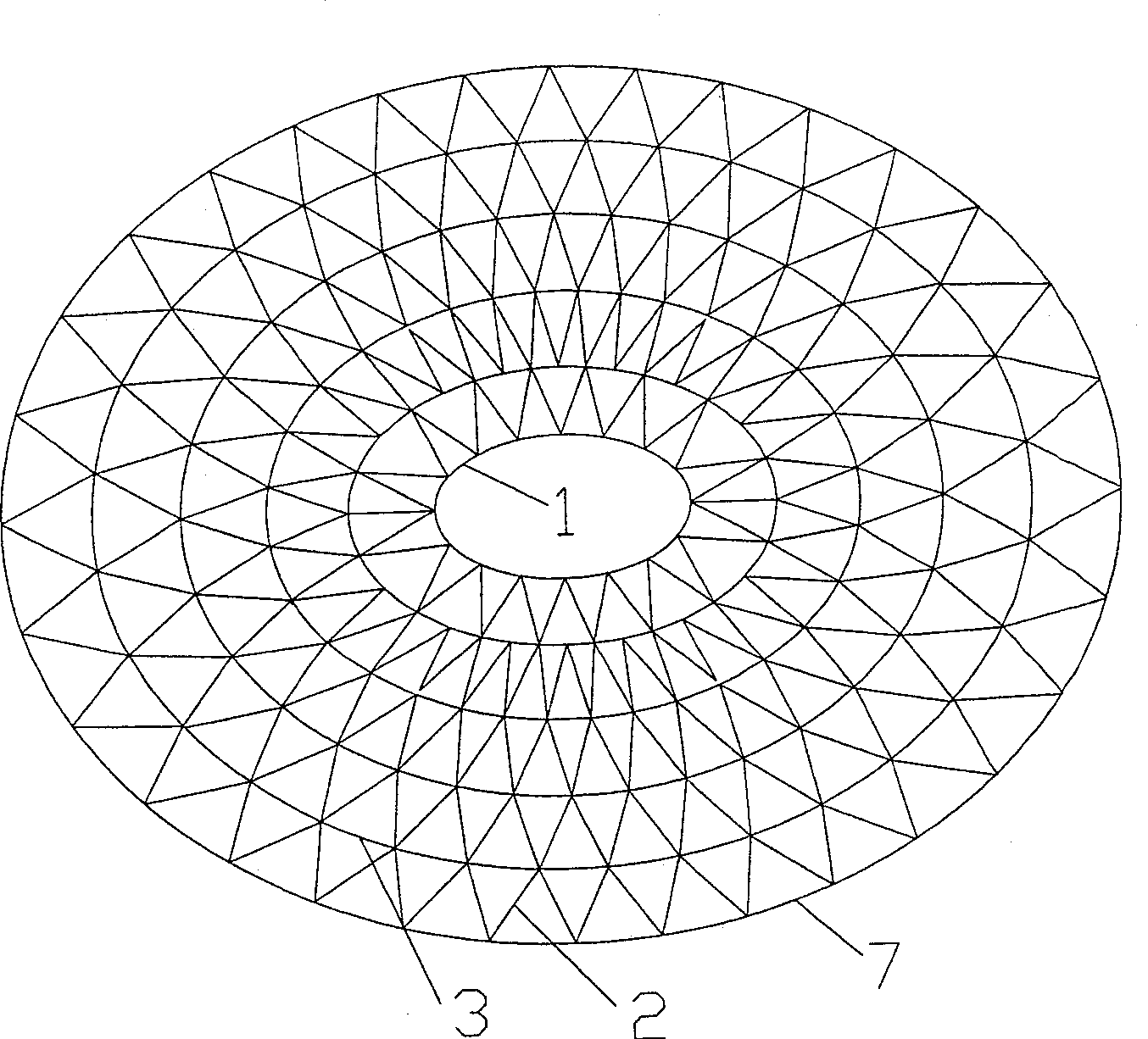

[0038] Such as image 3 , Figure 5 As shown, the structure of this embodiment is the same as that of Embodiment 1, the only difference is that the shape of the grid formed by the upper central pressure ring 1, the upper radial rod 2, the upper ring cable 3 and the side ring beam 7 is Oval. The length of strut 4 should guarantee that the angle of intersection between lower radial cable 5 and strut 4 is 70 degrees. The upper ring cable 3, the lower radial cable 5, and the lower ring cable 6 are selected as steel hinge lines, and the upper radial rod 2 is selected as a square steel pipe.

Embodiment 3

[0040] The structure of this embodiment is the same as that of Embodiment 1, the only difference is that the outline shape of the mesh composed of the upper central pressure ring 1, upper radial rod 2, upper ring cable 3 and side ring beam 7 is polygonal. The length of strut 4 should guarantee that the angle of intersection between lower radial cable 5 and strut 4 is 55 degrees. The upper ring cable 3, the lower radial cable 5, and the lower ring cable 6 are selected as cables, and the upper radial rod 2 is selected as section steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com