Basic shaft type SLM metal printer

A printer and base shaft technology, which is applied in the field of base shaft SLM metal printers, can solve the problems of single powder feeding, uncontrolled temperature stress of the workpiece, and affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Such as Figures 1 to 11 As shown, a base shaft type SLM metal printer, including a printer body and a metering powder feeding device;

[0068] The powder inlet of the metering powder feeding device is connected with the powder replenishing mechanism of the printer body through the powder feeding pipe;

[0069] The printer body includes a frame;

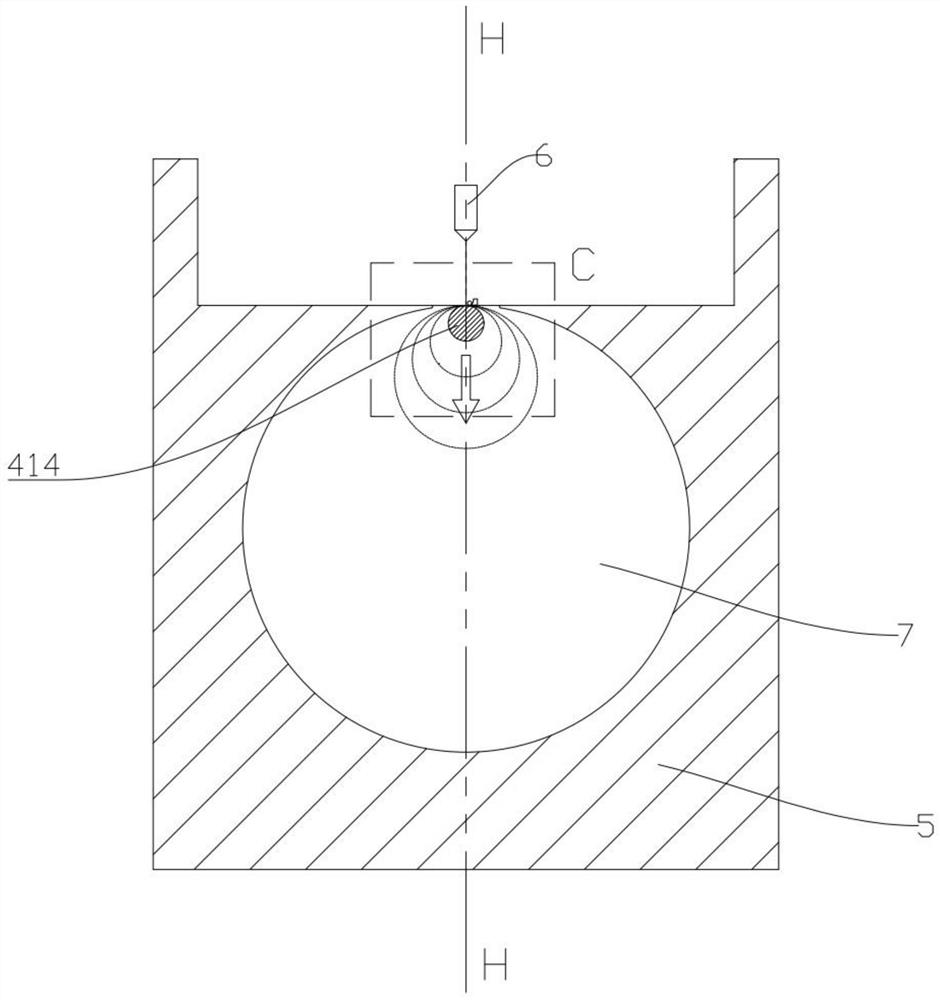

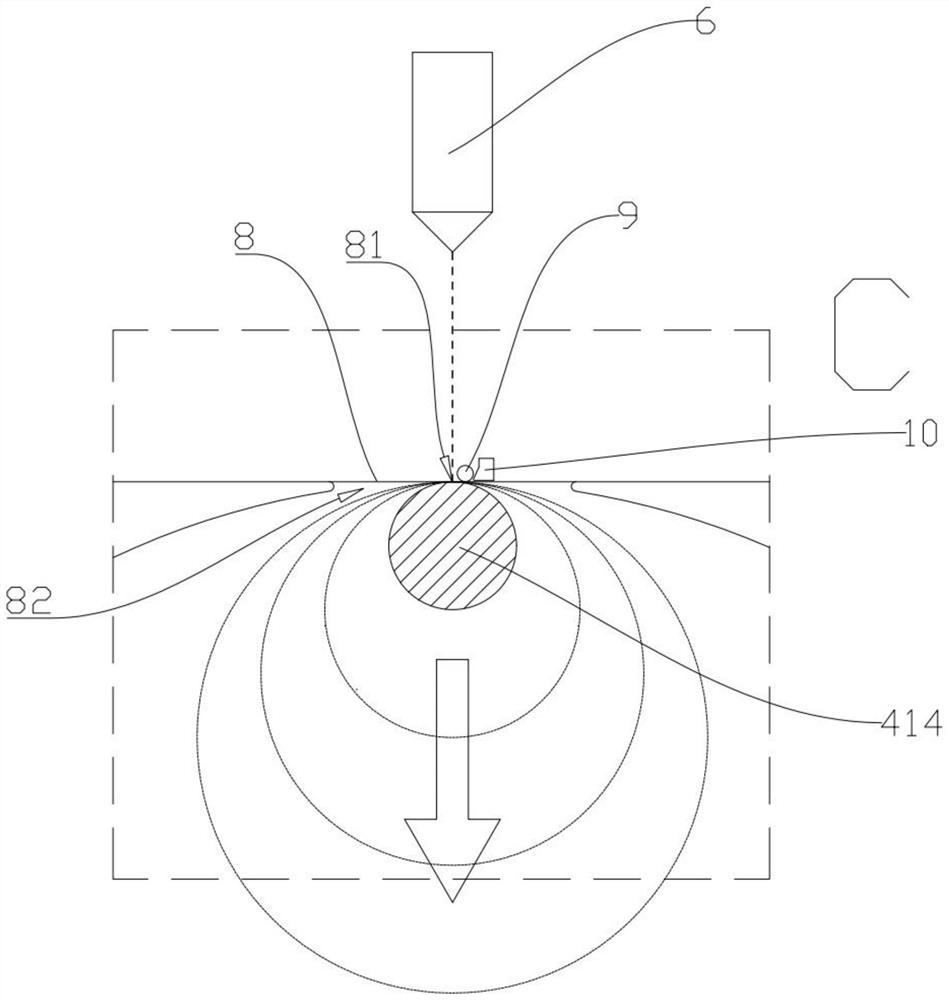

[0070] The middle part of the frame is provided with a powder cylinder;

[0071] The powder cylinder is in the shape of a cylinder, and its extension direction is parallel to the horizontal plane;

[0072] A base shaft driving device is arranged in the powder cylinder;

[0073] The mounting plates on both sides of the base shaft driving device are respectively detachably and fixedly connected to the inner lower surface of the powder cylinder;

[0074] The base shaft driving device is used to drive the base shaft to rotate and / or move up and down;

[0075] The extension direction of the base shaft is the same as the extens...

Embodiment 2

[0081] Such as Figures 1 to 11 As shown, a base shaft type SLM metal printer, including a printer body and a metering powder feeding device;

[0082] The powder inlet of the metering powder feeding device is connected with the powder replenishing mechanism of the printer body through the powder feeding pipe;

[0083] The printer body includes a frame;

[0084] The middle part of the frame is provided with a powder cylinder;

[0085] The powder cylinder is cylindrical, preferably cylindrical, and its extension direction (axis direction) is parallel to the horizontal plane;

[0086] A base shaft driving device is arranged in the powder cylinder;

[0087] The mounting plates on both sides of the base shaft driving device are respectively detachably and fixedly connected to the inner lower surface of the powder cylinder;

[0088] The base shaft driving device is used to drive the base shaft to rotate and / or move up and down;

[0089] The extension direction of the base shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com