Tea leaf cooling machine

A cooling machine and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of tea quality influence, long time, slow cooling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

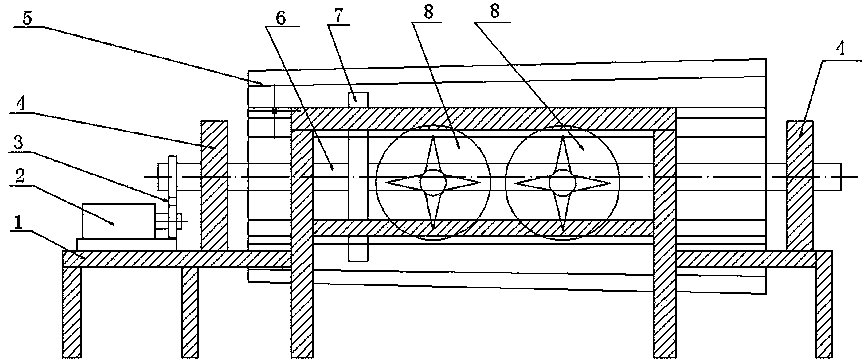

[0009] like figure 1 The shown tea cooling machine includes a frame 1 and a polygonal gauze cylinder 5. The polygonal gauze cylinder 5 has a bell mouth along the length direction, and the small end of the bell mouth is the feeding material of the polygonal gauze cylinder. The large end of the bell mouth is the discharge port of the polygonal gauze drum; the polygonal gauze drum 5 is supported on the support 4 of the frame through its rotating shaft 6, and the motor 2 is installed on the frame, and the motor 2 passes through the transmission pair 3 It is connected with the polygonal gauze cylinder 5 through transmission, and the polygonal gauze cylinder is located on the side of the feed port with a baffle blade 7, and there is a gap between the outer edge of the baffle blade 7 and the inner wall of the polygonal gauze cylinder 5; One side of the cylinder is provided with a plurality of cooling fans 8 along the long direction.

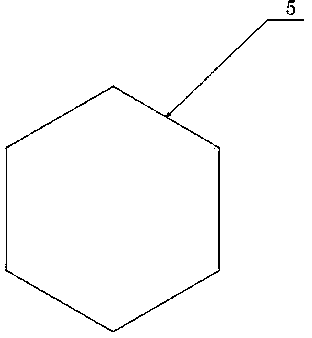

[0010] like figure 2 As shown, the cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com