Small product weighing device

A weighing device and product technology, applied in measuring devices, automatic feeding/discharging weighing devices, weighing, etc., can solve the problems of prolonged tablet or pill stabilization time, disturbed airflow, etc., and shorten the weighing time. time, increase productivity, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

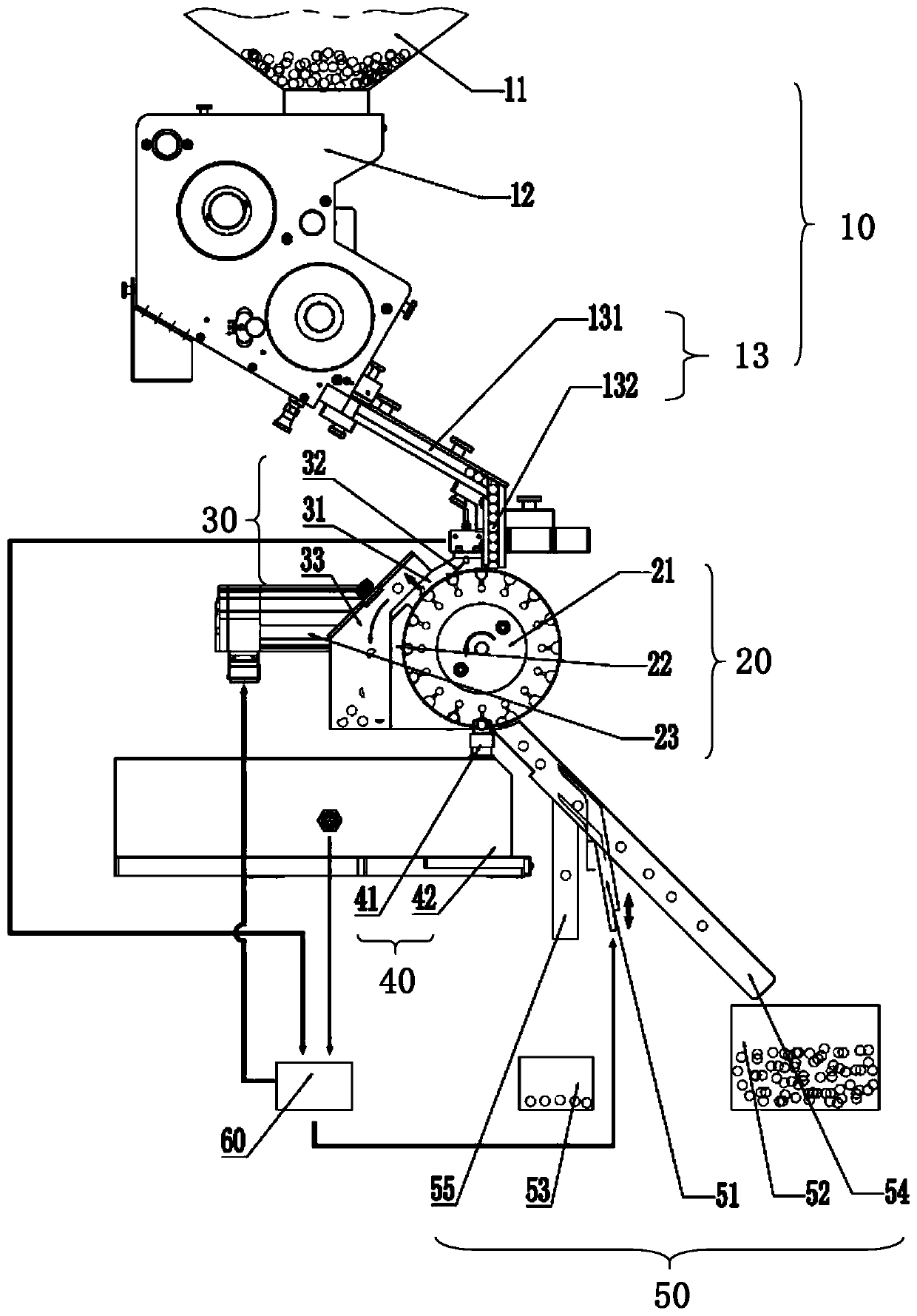

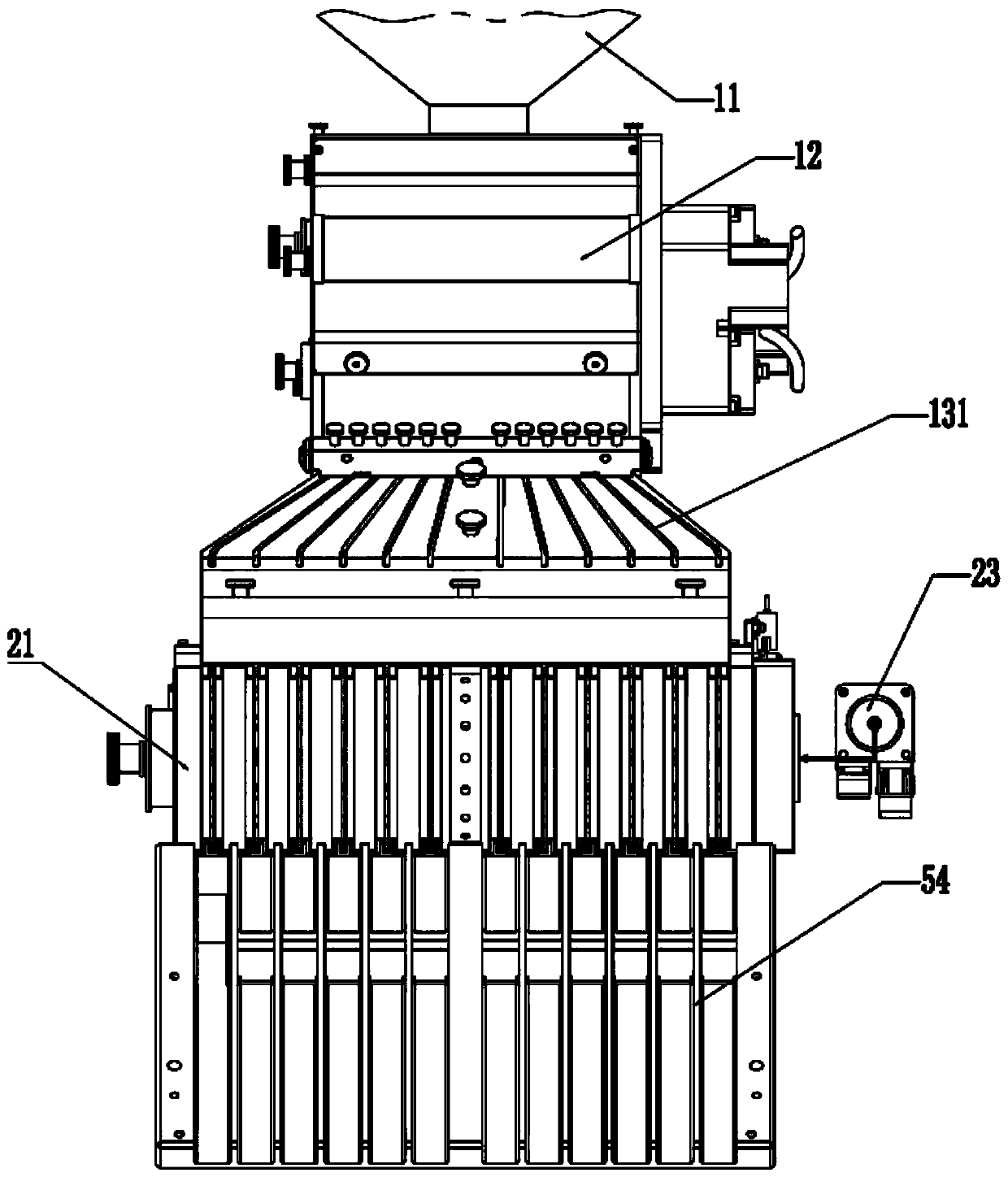

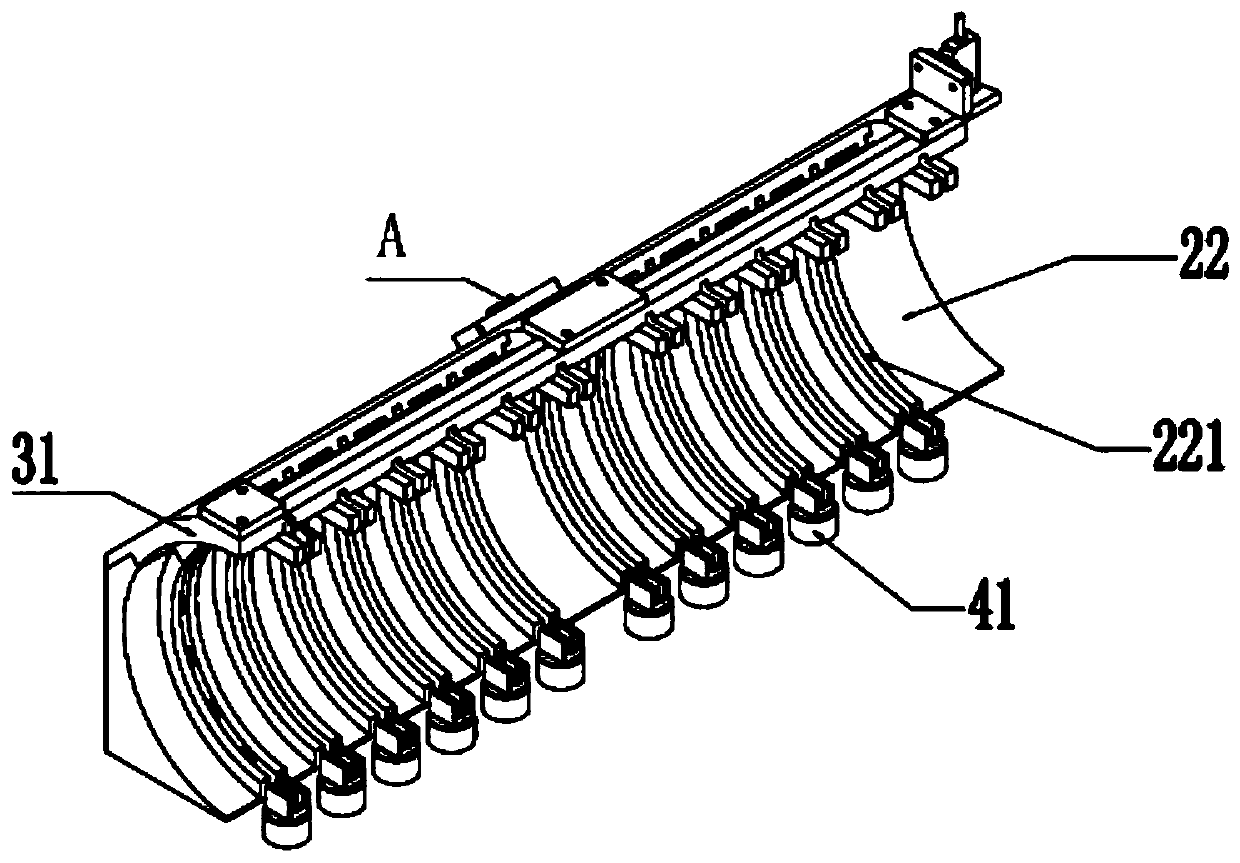

[0039] The preferred solution of the present invention is as follows: a weighing device for small products. According to the above structural description, this solution provides an optimal implementation solution. Such as image 3 As shown, the guide seat 22 is in the shape of a right triangle, and its hypotenuse is an arc-shaped conveying track 221 , and the arc-shaped conveying track 221 and the circumferential surface of the transfer hub 21 are fitted together. Such as Figure 4 As shown, the weighing platform 41 includes a U-shaped guardrail 411, a V-shaped positioning groove 412 and a base 413, the base 413 is placed on the load cell 42, and the U-shaped guardrail 411 is arranged above the base 413 The bottom of the hollow part of the U-shaped guardrail 411 is provided with the V-shaped positioning groove 412 , and the opening surface of the U-shaped guardrail 411 is aligned with the outlet end of the arc-shaped conveying track 221 .

[0040] Such as Image 6 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com