Manual cable stripping tool

A cable sheath, manual technology, used in cable installation, cable installation devices, equipment for dismantling/armoring cables, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

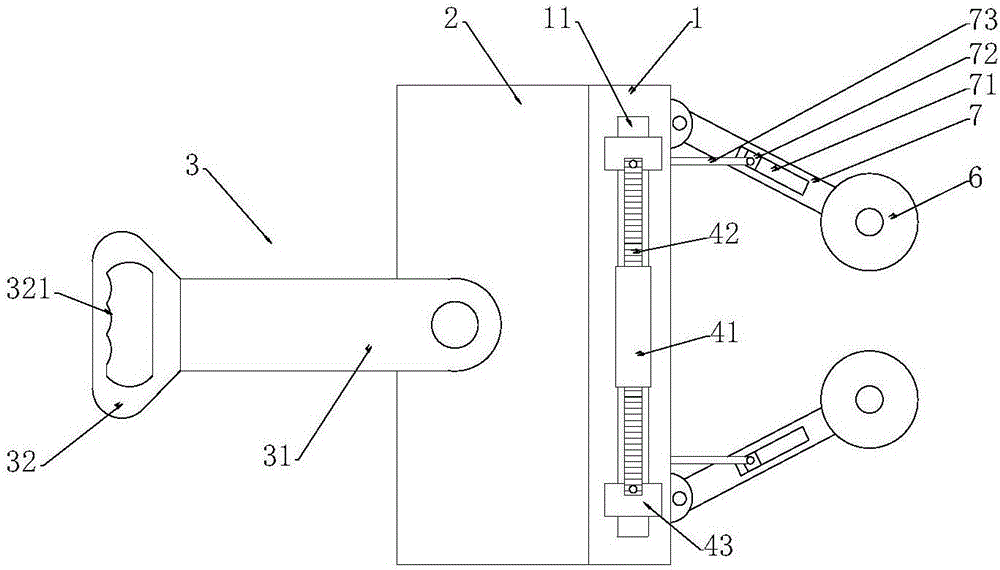

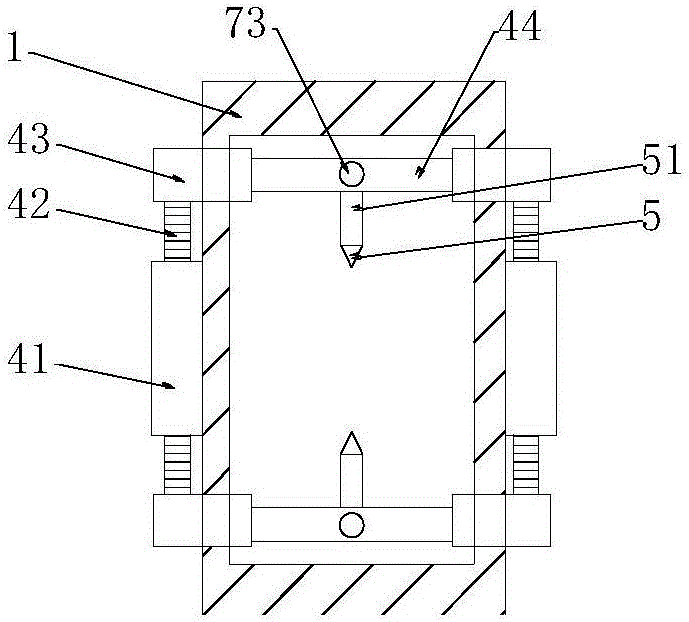

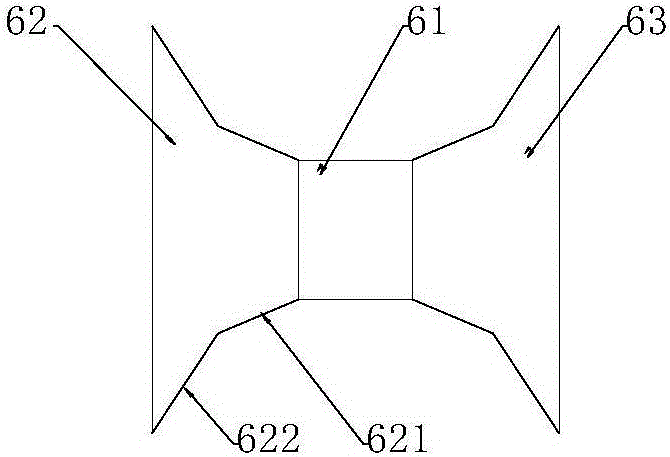

[0019] see Figure 1-4 , a manual cable sheath stripping tool, including a cutting part 1, a connecting part 2 and an operating part 3 connected in sequence; the cutting part 1 is a rectangular frame structure with front and rear openings, and the left and right sides of the cutting part 1 are arranged symmetrically Cutter feed mechanism is arranged, and cutter feed mechanism comprises screw mandrel sleeve 41, screw mandrel 42, first slide block 43 and strip block 44, and screw mandrel 42 has two to be connected on the upper and lower sides of screw mandrel sleeve 41 respectively. At both ends, the screw rod 41 is connected to the first slider 43, and the cutting part 1 is provided with a first chute 11 matching the first slider 43, and the first slider 43 and the first chute 11 are slidably engaged. In other words, the middle part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com