Garbage drying device

A drying device and garbage technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of large energy consumption, large energy consumption, heat loss of hot flue gas, etc., achieve good drying effect and improve utilization efficiency , to avoid the effect of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

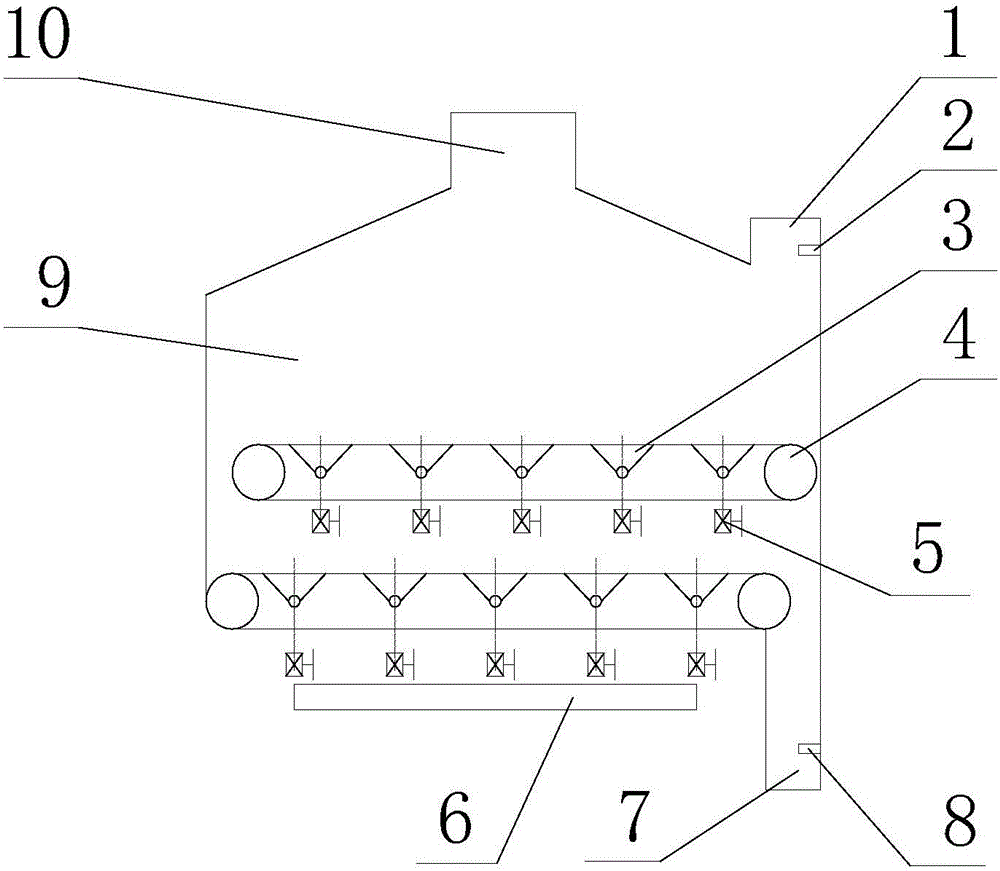

[0019] A garbage drying device, comprising a material inlet 1, a material outlet 7, an inlet moisture meter 2 and an outlet moisture meter 8, the wet garbage enters the grate 4 in the drying chamber 9 through the inlet 1, The row 4 moves together, and the air inlet 3 is evenly arranged under the grate. The hot flue gas injected by the air inlet 3 is used for drying the garbage. The opening degree of valve 5 is controlled. The water vapor evaporated from the hot flue gas and the garbage is discharged through the exhaust port 10.

[0020] There is a negative pressure in the drying chamber 9, which redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com