Glass tube secondary drawing apparatus and method thereof

A technology of glass tube and manufacturing method, which is applied in the field of glass tube secondary drawing device, can solve the problems that it is difficult to change glass types, and it is difficult to apply to prepare special glass tubes of many types and small batches, so as to facilitate the replacement of glass types and easy adjustment and the effect of controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

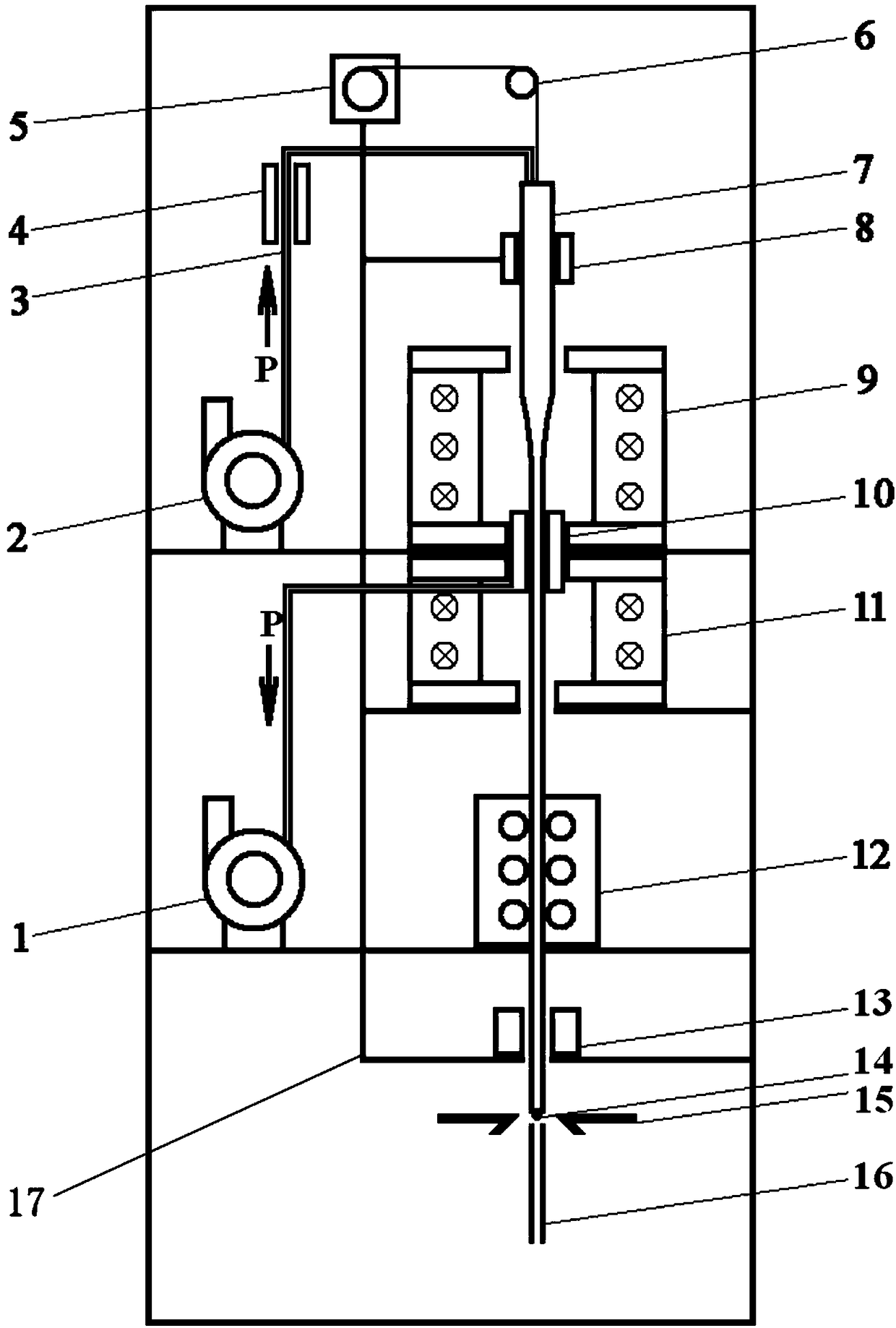

[0053] The glass tube secondary drawing device provided in this embodiment, such as figure 1 As shown, a feeding system is included to control the feeding speed and feeding verticality of the glass tube 7. The feeding system includes a feeding motor 5 that can be steplessly speed-regulated to control the feeding speed of the glass tube 7; a stabilizing ring 8 , used to adjust the feeding verticality of the glass tube 7 to ensure the straightness of the secondary drawn tube. The drawing system is used to heat and soften the glass tube 7 and draw it, including a heating furnace 9 and an annealing furnace 11, and the heating furnace 9 and the annealing furnace 11 are oppositely provided with through holes suitable for the passage of the glass tube 7 , the annealing furnace 11 is located below the heating furnace 9, and the setting of the annealing furnace 11 is to prevent bursting when drawing short-cut glass tubes through gradient cooling, so as to improve the yield; the mold 10...

Embodiment 2

[0063] This embodiment provides a glass tube secondary drawing method, using the glass tube secondary drawing device as described in Example 1, comprising the following steps:

[0064] Adopt the following weight percentage composition: 56.3% SiO 2 ; 13.9% ZrO 2 ; 8.9% CaO; 7.5% Na 2 O; 6.6% BaO; 4.3% B 2 o 3 ; 1.6% Al 2 o 3 and 0.9% MgO in a glass tube. Glass tube size is Φ 外 32×Φ 内 22×500mm, without defects such as bubbles, streaks and stones.

[0065] Put the glass tube 7 vertically into the heating furnace 9 through the feeding motor 5 and the stabilizing ring 8 for heat treatment. The heating rate in the heating furnace 9 is 0.3°C / min. The heat preservation temperature is 850±0.5°C, and the glass tube is kept vertical. The glass tube softens, first moves downward through its own gravity, and enters the annealing furnace 11 through the mold 10. The temperature of the annealing furnace 11 is 630°C. ≤10°C / cm. Then drawing is carried out under the action of the trac...

Embodiment 3

[0068] This embodiment provides a glass tube secondary drawing method, which uses the glass tube secondary drawing device as described in Example 1, comprising the following steps:

[0069] Adopt the following weight percentage composition: 56.3% SiO 2 ; 13.9% ZrO 2 ; 8.9% CaO; 7.5% Na 2 O; 6.6% BaO; 4.3% B 2 o 3 ; 1.6% Al 2 o 3 and 0.9% MgO in a glass tube. Glass tube size is Φ 外 64×Φ 内 45×500mm, without defects such as bubbles, streaks and stones.

[0070] Put the glass tube 7 vertically into the heating furnace 9 through the feeding motor 5 and the stabilizing ring 8 for heat treatment. The heating rate in the heating furnace 9 is 0.3°C / min. The heat preservation temperature is 900±0.5°C, and the glass tube is kept vertical. The glass tube softens, first moves downward through its own gravity, and enters the annealing furnace 11 through the mold 10. The temperature of the annealing furnace 11 is 630°C. ≤10°C / cm. Then drawing is carried out under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com