Smashing device for manufacturing amino molding plastic

A technology of amino molding compound and crushing device, which is applied in the direction of grain processing, etc., can solve the problems of insufficient efficiency, low production efficiency, lack of specificity of amino molding compound, etc., and achieve the effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

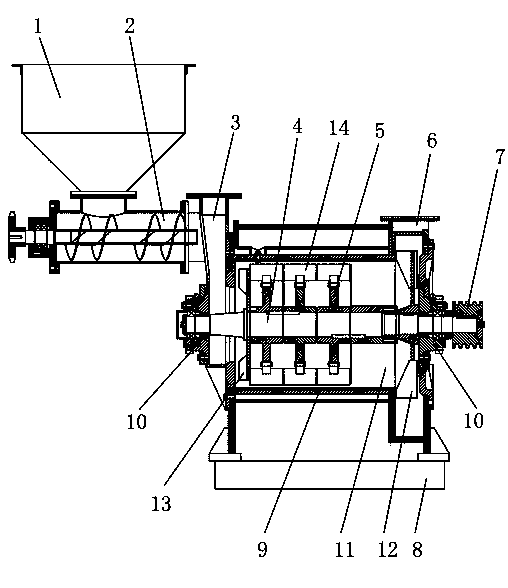

[0009] The production method of the amino molding compound involved in the present invention is as follows: first, formaldehyde, urea and other auxiliary materials are reacted in a reactor to obtain urea-formaldehyde resin, and the urea-formaldehyde resin is added to pulp and other additives and entered into a kneader for meshing to obtain Slurry, the slurry is put into a drier to dry to obtain a solid material, the solid material has uneven particle size and contains many block materials. The drying moisture of the solid material is controlled below 5%, preferably around 3%; tests have proved that when the moisture of the solid material is controlled at 3%, the crushing output of the high-speed eddy current pulverizer can reach up to 800 Kg / h; and When the moisture is about 5%, the crushing output will drop to about 500 Kg / h. The lower the moisture, the better the crushing effect and output, but it is extremely difficult to control the moisture of the aforementioned solid mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com