Method for increasing solid-liquid separation rate of raw tobacco powder raw material in tobacco reconstituting process

A technology for reconstituted tobacco leaves and solid-liquid separation, which is applied in the fields of tobacco, tobacco preparation, and application, and can solve the problems such as hovering around 15%, clogging the inlet of the pressing equipment, overflowing the dryness of the discharged material, and failing to reach 37%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 (comparative test)

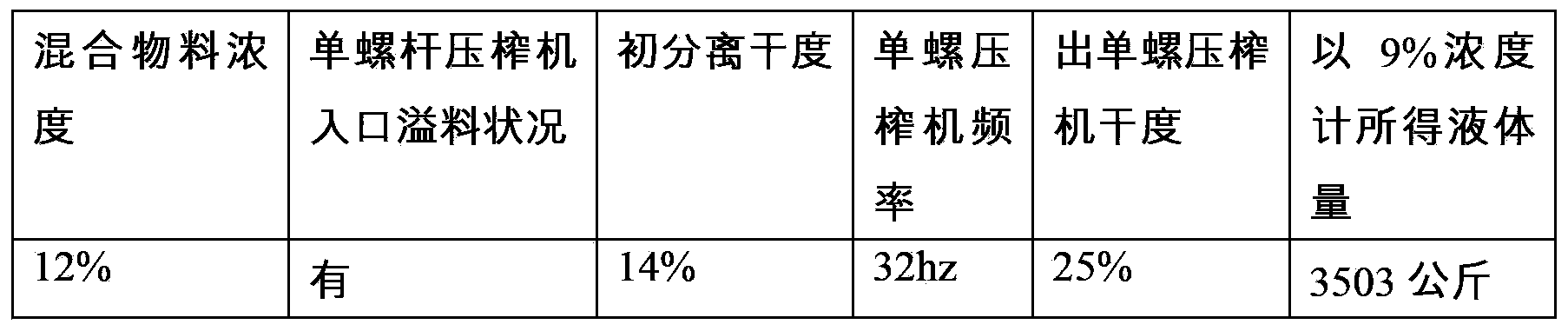

[0013] 600kg contains 20% crushed leaves, 25% soot, 25% cigarette sticks, and 30% tobacco dust. After soaking, the mixed production material with a water content of 88% is obtained. Use a vertical mixing tank to control the valve opening to control the discharge speed. The solid-liquid mixed production materials are put into a leaking screw device, and the solid-liquid separation is carried out through the leaking screw, and then directly conveyed into the single-screw press by the inclined screw to form a complete set of solid-liquid separation system. The data obtained are shown in Table 1:

[0014] Table 1

[0015]

Embodiment 2

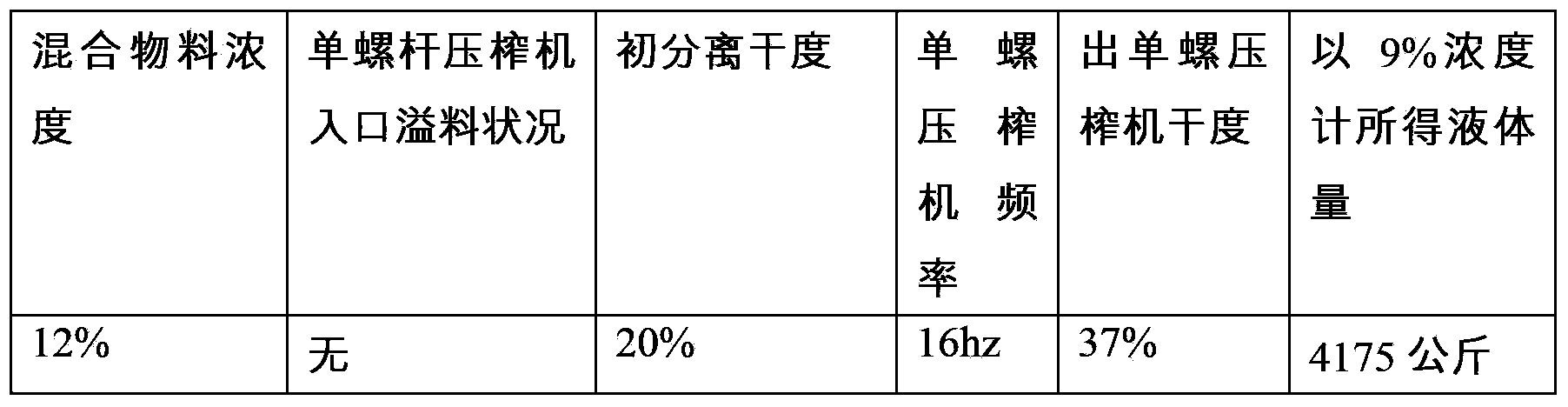

[0017] 600kg contains 20% of crushed leaves, 25% of soot, 25% of cigarette sticks, and 30% of tobacco dust. After soaking, a solid-liquid mixed production material with a water content of 88% is obtained. A vertical mixing tank is used to control the opening of the valve to make the solid-liquid mixed production material Enter the volumetric pump, the mixed material is controlled by the flowmeter concentration meter and enters a centrifugal extruder at a uniform speed, and then the liquid obtained by preliminary separation is carried out through the centrifugal extruder and the subsequent single-screw extruder extrudes the slag-containing liquid using a liquid pump. On the 100-mesh linear vibrating screen, the liquid is preliminarily screened at a working intensity of 10 times per second and an amplitude of 9mm. The obtained slag and the dry slag obtained from the centrifugal extruder are mixed and transported to the single The screw extruder is used for squeezing solid-liquid ...

Embodiment 3

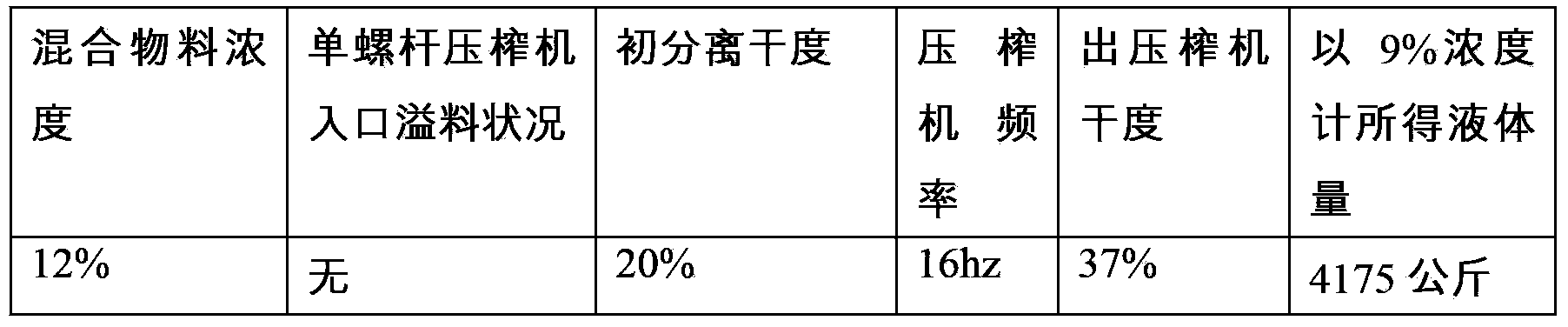

[0021] 600kg contains 10% of broken leaves, 30% of soot, 25% of cigarette sticks, and 35% of tobacco dust. After soaking, the solid-liquid mixed production material with a water content of 88% is obtained. Use a vertical mixing tank to control the opening of the valve to make the solid-liquid mixed production material Enter the volume pump, and the mixed material is controlled by the flow meter concentration meter to enter a centrifugal extruder device at a uniform speed, and then the liquid obtained by preliminary separation is carried out through the centrifugal extruder and the subsequent single-screw extruder extrudes the slag-containing liquid using a liquid pump The liquid is preliminarily screened on the 100-mesh linear vibrating screen with a working intensity of 10 times per second and an amplitude of 9 mm. The obtained slag and the dry slag obtained from the centrifugal extruder are mixed and transported to the The single-screw press performs press-type solid-liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com