Rolling wheel extruder for preparing cylindrical particle fuels

A pellet fuel and extruder technology, which is applied in the direction of material molding presses, solid fuels, fuels, etc., can solve the problems of high cost, high cost, and failure of gas turbines to operate normally, and achieve the effect of reduced preparation cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

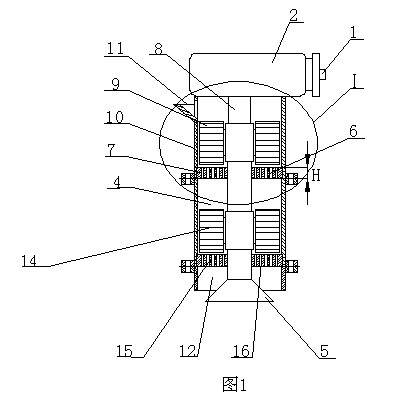

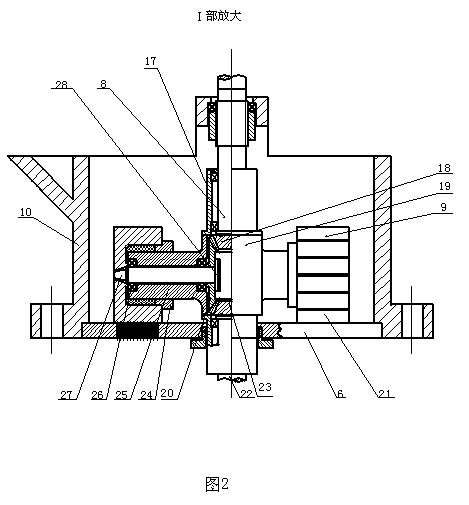

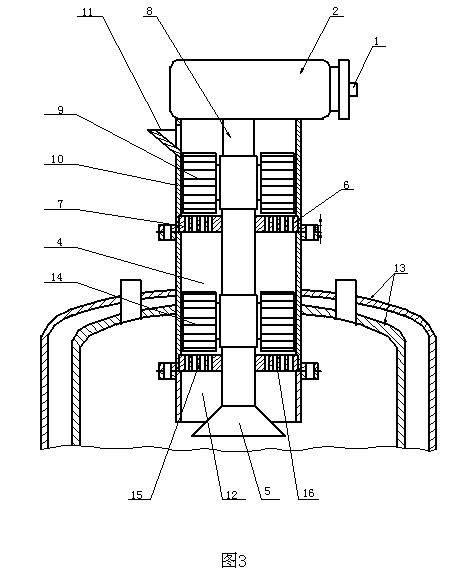

[0008] The present invention will be further described with reference to the accompanying drawings.

[0009] A roller extruder for preparing cylindrical granular fuel according to the present invention includes a material receiving barrel 10, a first transmission shaft 8 is vertically installed in the material receiving barrel 10, and the first transmission shaft 8 is connected to the transmission part in the power transmission box 2 , the first group of rolling wheels 9 is installed on the first transmission shaft 8, and the first group of rolling wheels 9 is at least two, which are installed on both sides of the first transmission shaft 8 respectively. Disc 6, the first circular steel disc 6 is located below the first group of rolling wheels 9, several first columnar through holes 7 are offered on the first circular steel disc 6, the first circular steel disc 6 is provided with A cylindrical through hole 7 is distributed on the track where the roller rotates around the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com