Constant force compensation device

A compensation device, constant force technology, applied in grinding automatic control device, grinding/polishing safety device, grinding machine, etc., can solve the problem of not being able to control the feed speed of the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

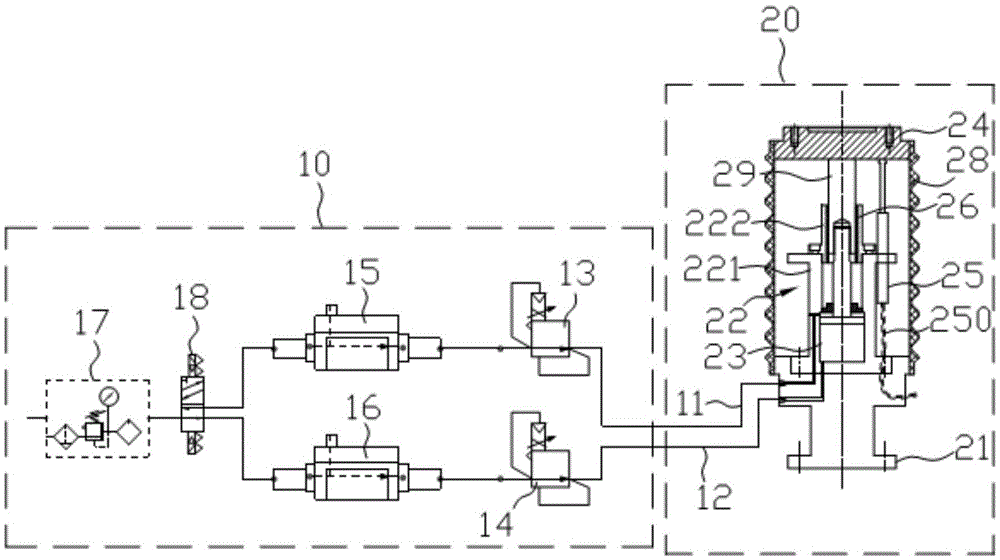

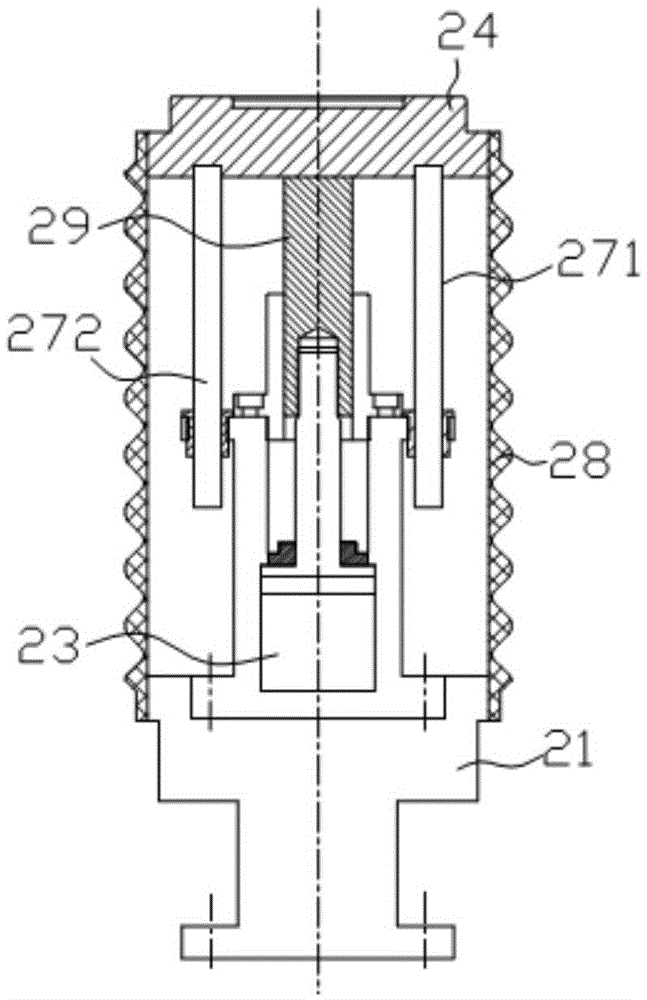

[0023] combine figure 1 , figure 2 , a constant force compensation device, including a constant force control part 10 and a constant force execution part 20.

[0024] The constant force control part 10 includes an air source system, an air intake pipeline 11 and an exhaust pipeline 12 connected to the air source system, a first electric proportional valve 13 and a first digital flow controller 15 arranged on the air intake pipeline, The second electric proportional valve 14 and the second digital flow controller 16 arranged on the exhaust pipeline are electrically connected with the first electric proportional valve and the second electric proportional valve and the first digital flow controller and the second digital flow controller main control system.

[0025] In the above-mentioned constant force control part 10, the air source system includes an air source, an air source processor 17, and an electromagnetic valve 18, and the air source processor and the electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com