Novel spline shaft upsetting forging die structure

A spline shaft and upsetting technology, which is applied to forging/pressing/hammer devices, forging/pressing/hammering machinery, mechanical equipment, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive, etc., and improve the overall efficiency and improve efficiency , to ensure the effect of vertical force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

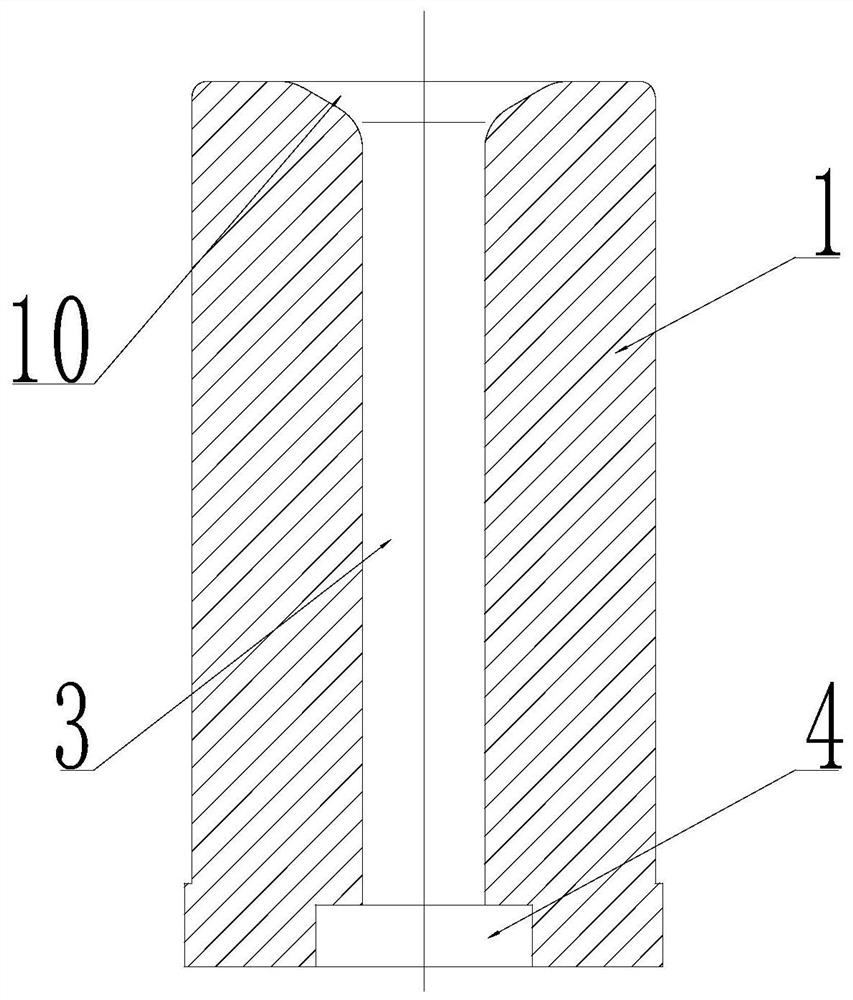

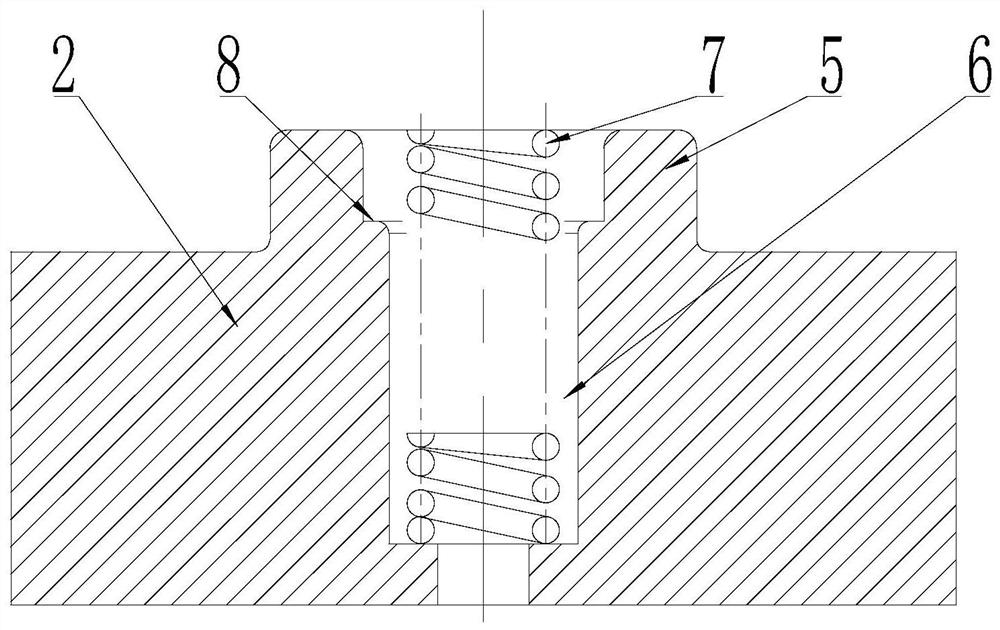

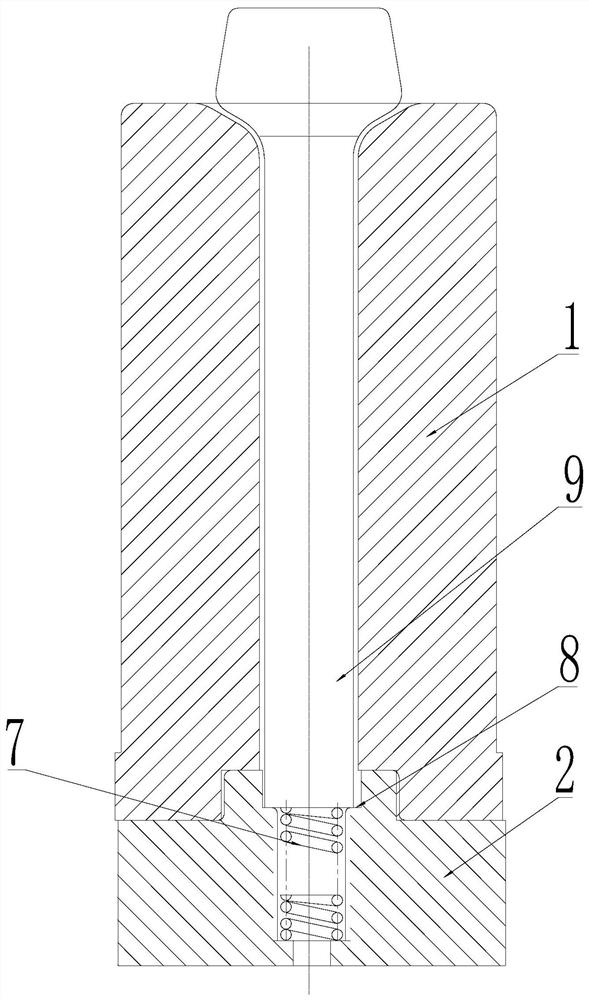

[0013] Embodiment: As shown in the accompanying drawings, this new type of spline shaft upsetting forging die structure is used to pier a blank 9, one end of the blank 9 is a rod 9-1, and the other end of the blank 9 is a pier Part 9-2, the structure includes an upset upper die 1 and a pier lower die 2. Such as figure 1 As shown, a blank passage 3 is provided through the upper die 1 for upsetting, and the inner diameter of the bottom of the blank passage 3 expands to form a concave interface 4; as figure 2 As shown, the top of the pier thick lower die 2 is provided with a convex interface 5 corresponding to the concave interface 4, and the convex interface 5 and the concave interface 4 are embedded and matched so that the upsetting upper die 1 is supported on the pier thick lower die 2; The interface 5 is provided with a spring groove 6 for inserting the spring 7, and the inner wall of the top end of the spring groove 6 is provided with a step surface 8, and the rod portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com