Floor type brake master cylinder performance test device and method

A technology of a brake master cylinder and a test device, applied in the automotive field, can solve the problem that the force direction of the pedal force sensor is difficult to guarantee, the force position of the pedal force sensor cannot be maintained at all times, and the performance test error of the floor-type brake master cylinder is large. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

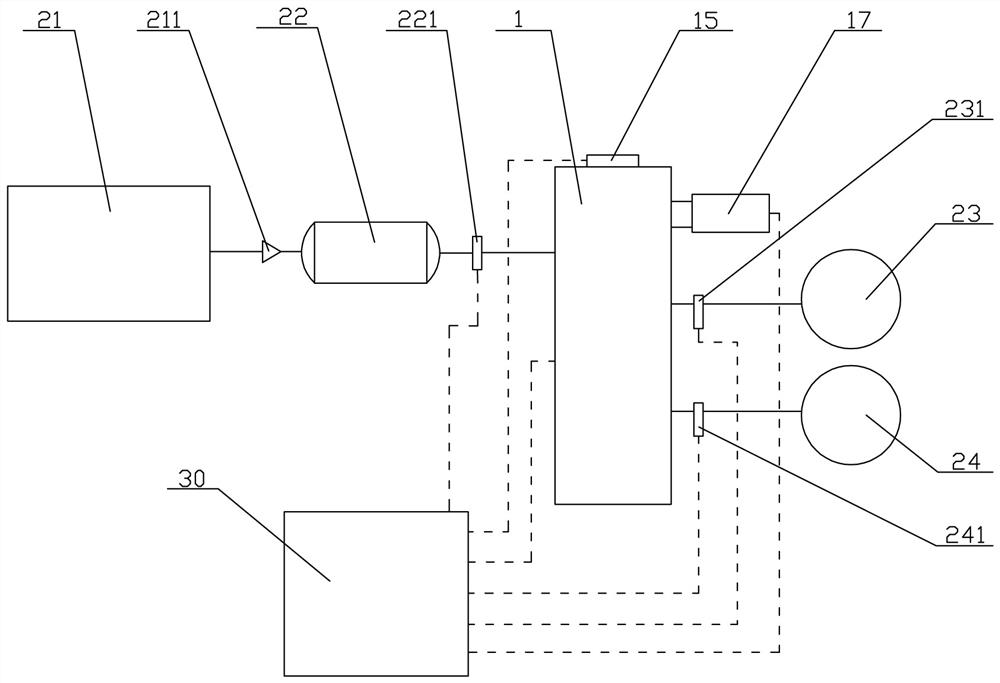

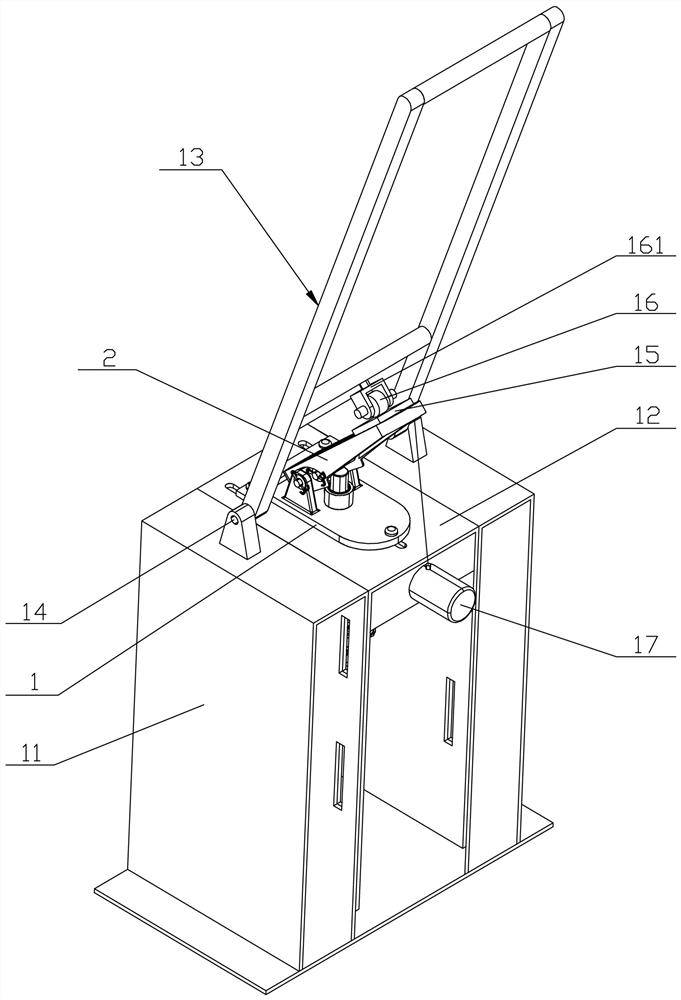

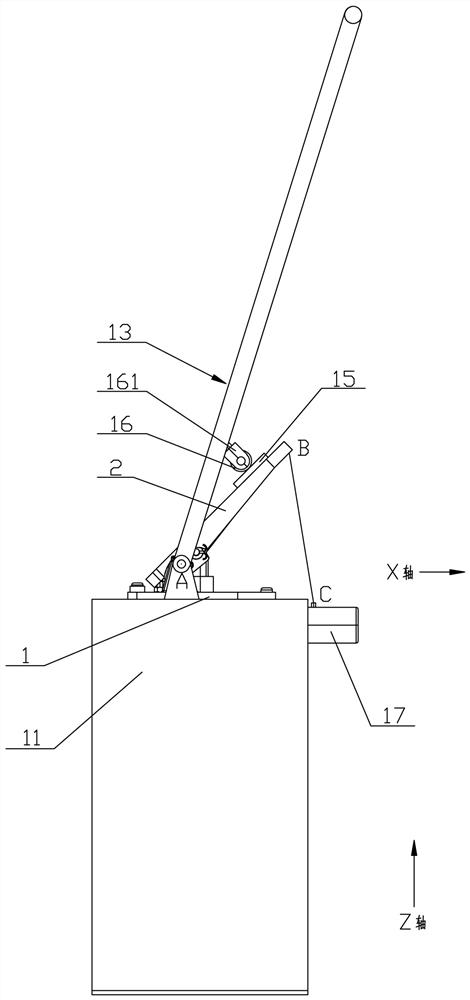

[0036] A floor type brake master cylinder performance test device, refer to figure 1 with figure 2 , including brake master cylinder test tooling and air source system. The brake master cylinder test tool includes a fixed base 11, an adjustable support 12 and a pressure rod mechanism 13. The adjustable support 12 is arranged on the fixed base 11, and the brake master cylinder 1 is fixedly installed on the adjustable support 12. The brake master cylinder 1 is connected with the air source system. The pressure rod mechanism 13 is rotatably installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com