Mill roll system for flattening irregular metal part and flattening rolling method

A technology for special-shaped parts and metals, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve problems such as inability to flatten and roll, marks on the surface of the plate, and inability to guarantee the initial thickness of the plate, so as to maintain the original thickness. The surface quality is good and the effect of avoiding self-damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A rolling mill roll system for flattening metal shaped parts. The upper and lower work rolls are composed of 2~4 curved parts and 2~5 straight parts, and the two ends along the length direction of the roll body are straight parts, and the straight lines The length of the part is 30~52.36mm, the angle between the tangent line and the horizontal line at the two ends of each curved part is 0~75°, and the curved part and the curved part or the curved part and the straight part are connected smoothly; the roll system The length of the roll body is 120mm, the minimum roll diameter is φ86.6~117.2mm, and the maximum roll diameter is φ118mm.

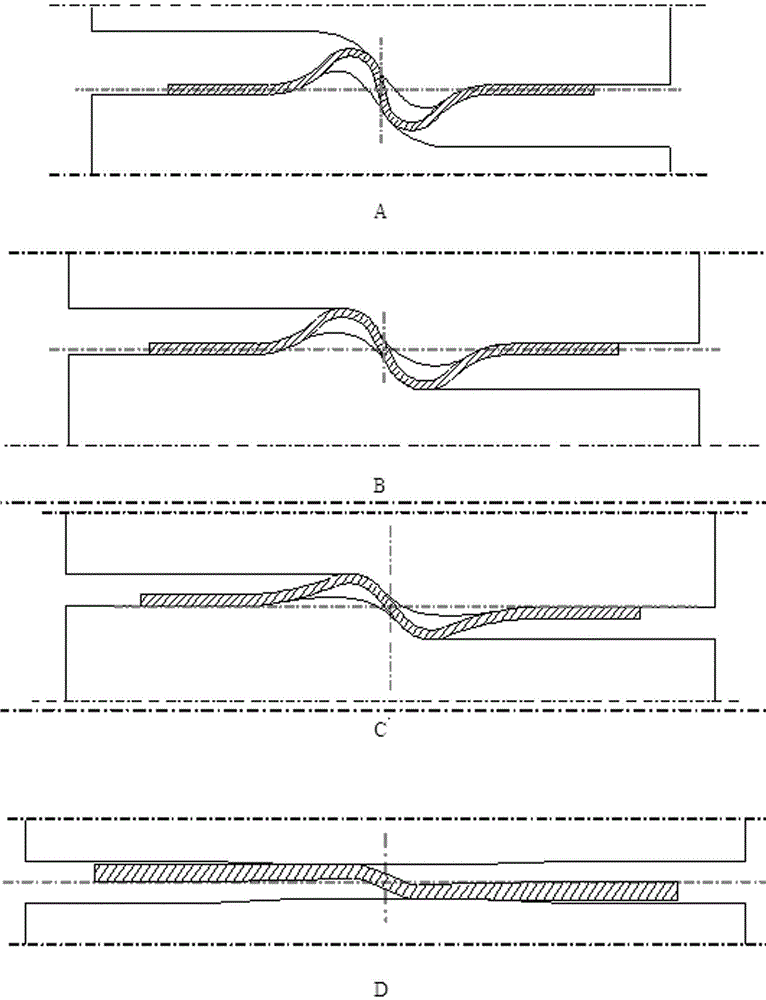

[0023] The method for flattening and rolling metal special-shaped parts by using the roll system is carried out according to the following process steps:

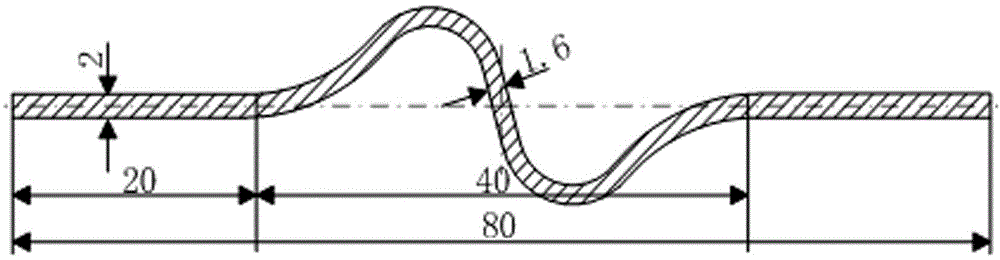

[0024] (1) Prepare industrial pure aluminum special-shaped parts with a thickness of 1.6~2mm and a width of 80mm. The cross-sectional diagram is as follows figure 1 As shown, the roll ...

Embodiment 2

[0027] A rolling mill roll system for flattening metal shaped parts. The upper and lower work rolls are composed of 6 sections of curved parts and 2 sections of straight lines, and the two ends along the length direction of the roll body are straight parts, and the lengths of the straight parts at both ends are respectively 39.7mm and 30.75mm, the angle between the tangent line and the horizontal line at the two ends of each curve part is 0~30°, and the curve part and the curve part are connected smoothly; the length of the roll body of the roll system is 120mm, and the minimum roll The diameter is φ109.58mm, and the maximum roll diameter is φ118mm.

[0028] The method for flattening and rolling metal special-shaped parts by using the roll system is carried out according to the following process steps:

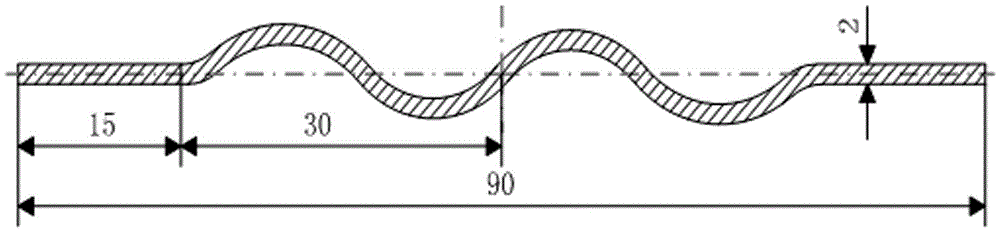

[0029](1) Prepare industrial pure copper special-shaped parts of equal thickness with a thickness of 2mm and a width of 90mm. The cross-sectional diagram is as follows image...

Embodiment 3

[0032] A rolling mill roll system for flattening metal shaped parts. The upper and lower work rolls are composed of 6~9 sections of curves and 4~7 sections of straight lines. The length of the part is 35~81.01mm, the angle between the tangent line and the horizontal line at the two ends of each curved part is 0~75°, and the curved part and the curved part or the curved part and the straight part are connected smoothly; the roller system The length of the roll body is 260mm, the minimum roll diameter is φ159.5~179.2mm, and the maximum roll diameter is φ180mm.

[0033] The method for flattening and rolling metal special-shaped parts by using the roll system is carried out according to the following process steps:

[0034] (1) Prepare special-shaped pieces of ordinary carbon steel (Q235) with a thickness of 1.6~2mm and a width of 170mm. The cross-sectional diagram is as follows Figure 5 As shown, the roll bending process is adopted, and the upper and lower working rolls of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com