Rapid test sample tensile stress corrosion tester

A rapid corrosion and testing machine technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of arm error, recording time, concentration reduction, etc., to speed up the experiment cycle and improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

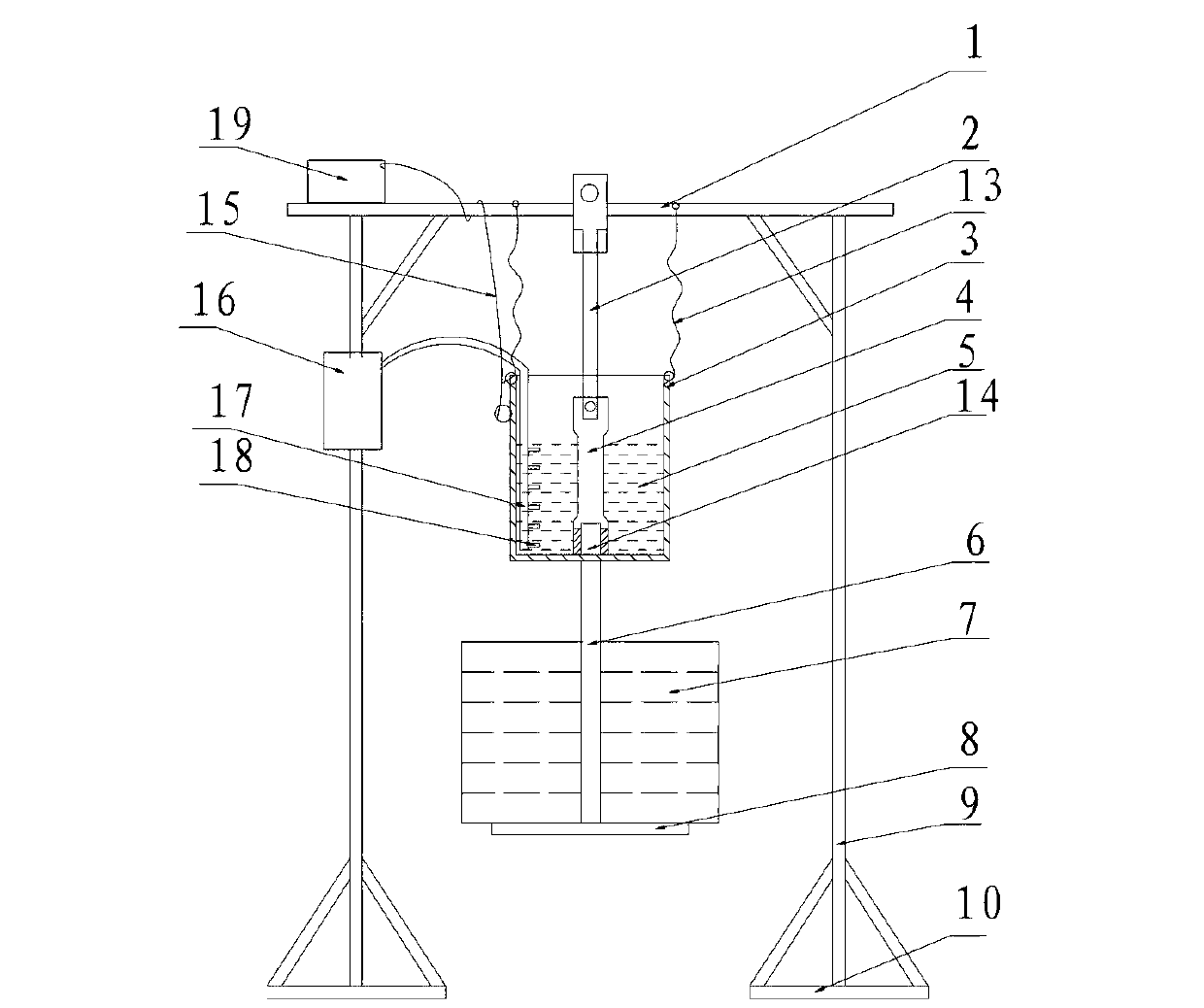

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0027] Such as Figure 2-4 As shown, a sample tensile stress rapid corrosion test machine includes a corrosion cup 3 and a timing stirring device for the corrosion solution. The corrosive liquid timing stirring device includes a main air pipe 17 inserted in the corrosion cup 3 , a branch air pipe 18 connected to the main air pipe 17 and an air pump 16 connected to the main air pipe 17 . During specific implementation, the air pump 16 is controlled by a timer, such as stirring for 10 seconds after 1 hour, to effectively ensure the concentration of the corrosion solution around the sample.

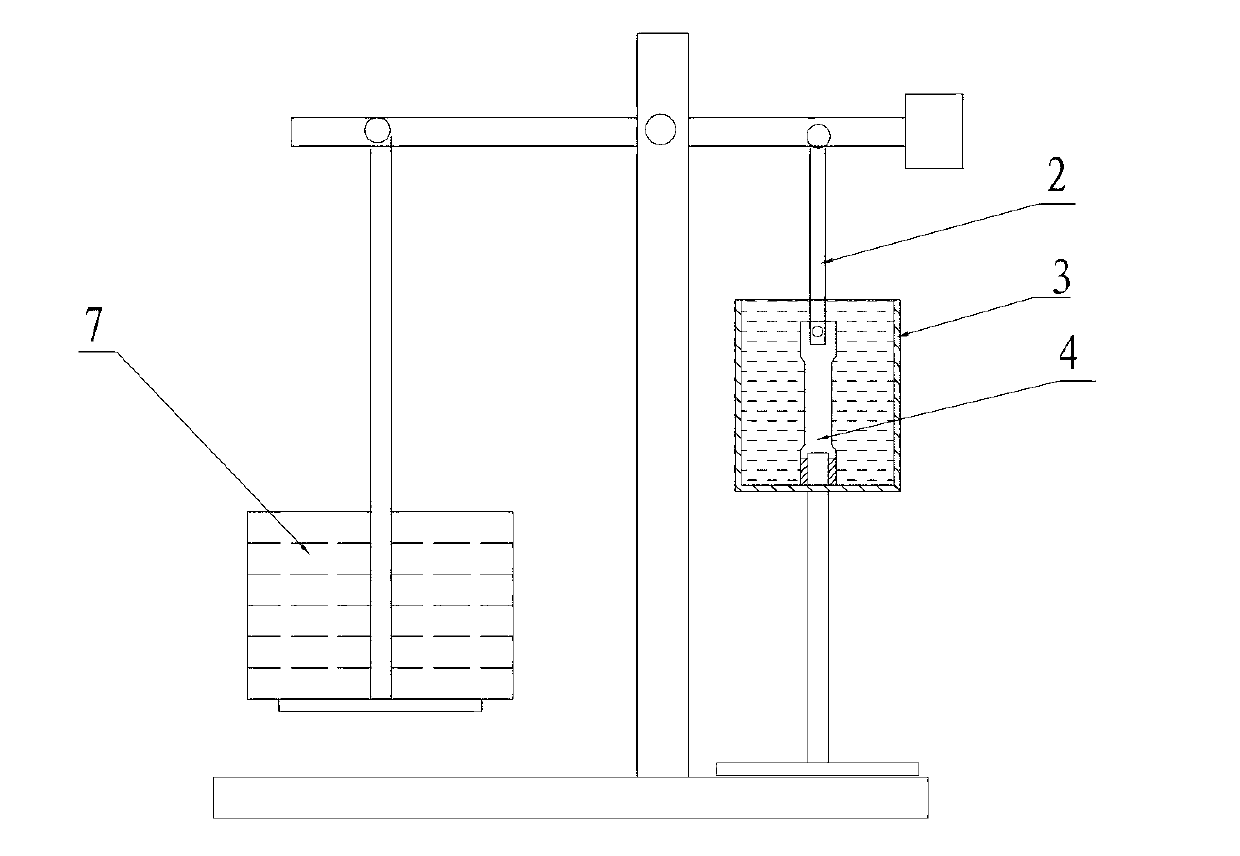

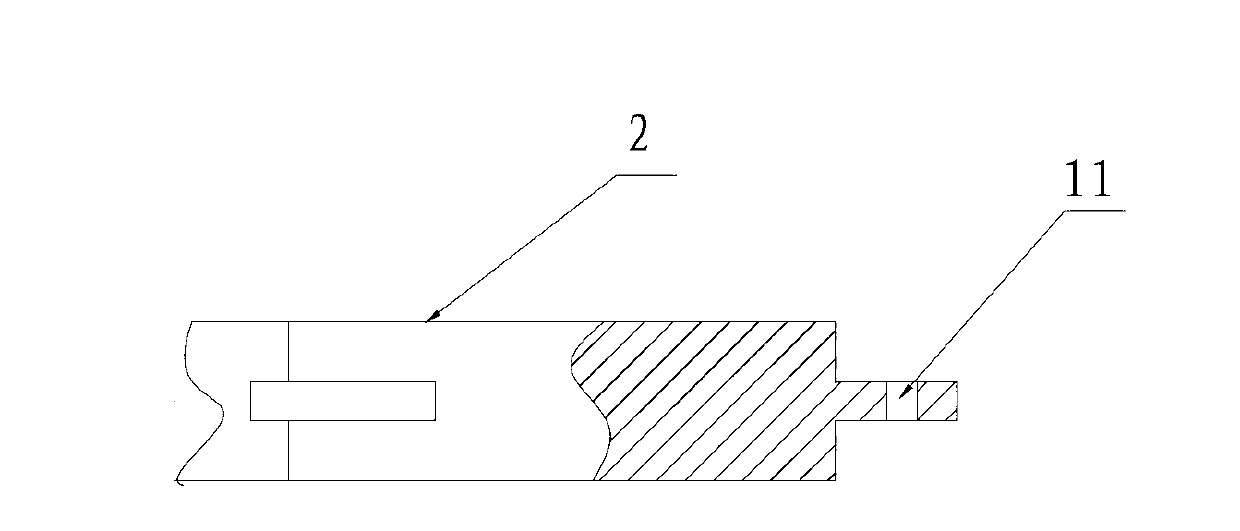

[0028] It also includes a bracket, a weight 7, an upper draw bar 2 and a lower draw bar 6, the support includes a beam 1, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com