Automatic crushing equipment used for production of sulphate-resistant cement

A technology of anti-sulfate cement and crushing equipment, applied in the direction of grain processing, etc., can solve the problems of uneven heating and uneven discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

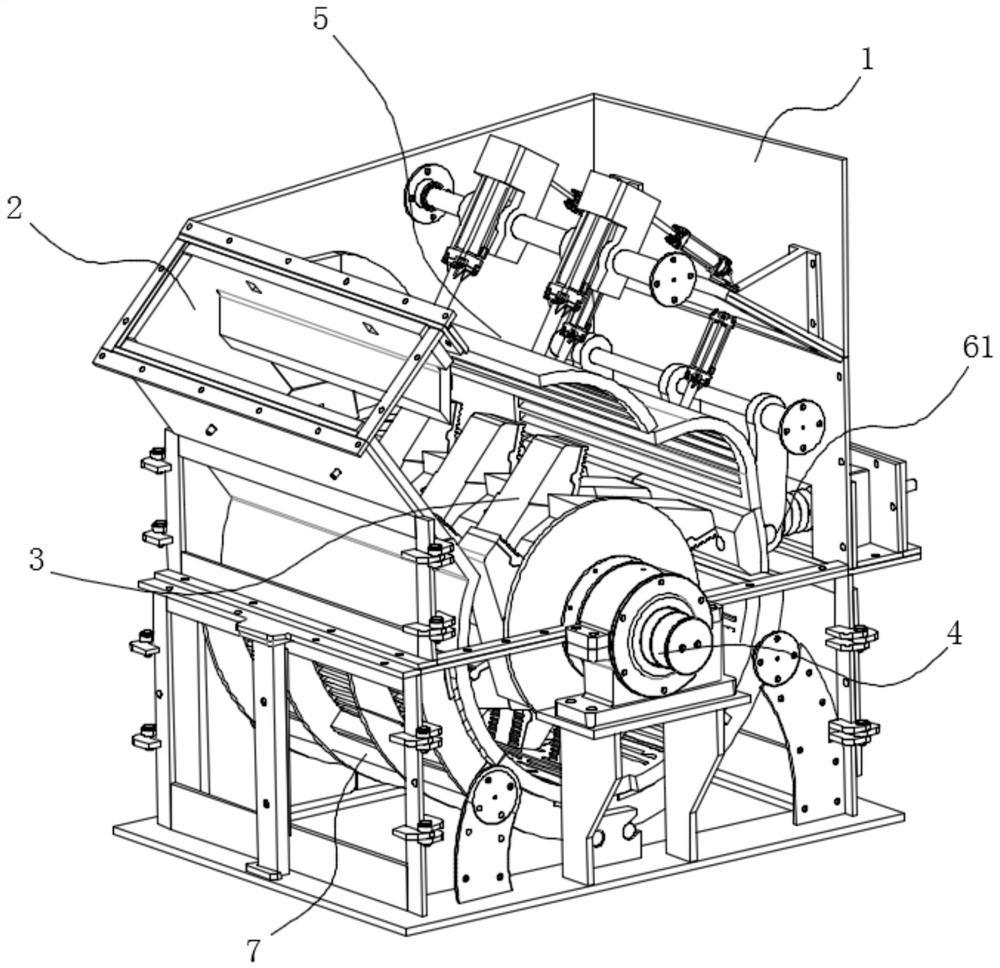

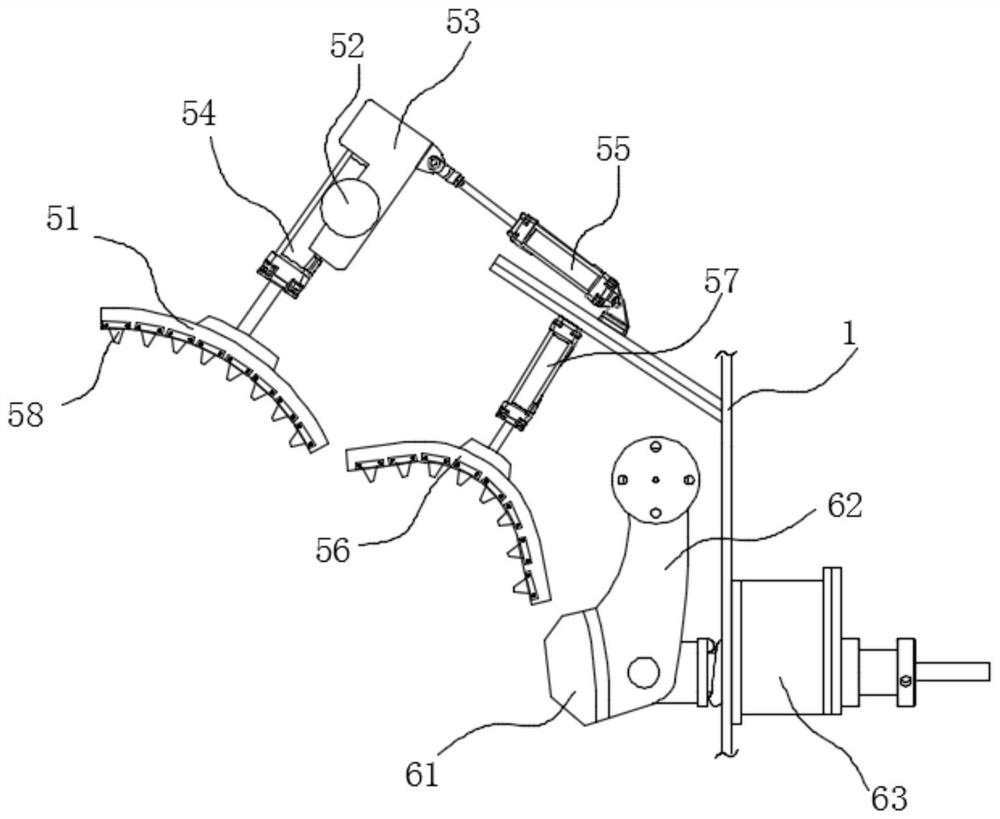

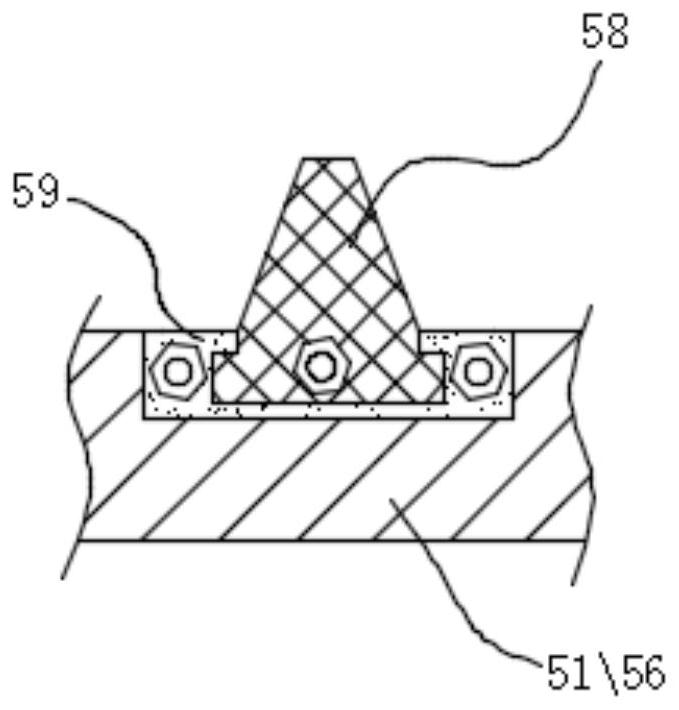

[0030] see figure 1 , in the embodiment of the present invention, an automatic crushing equipment for sulfate-resistant cement production, including a frame 1, a rotary hammer assembly 3, and an impact plate assembly 5, wherein a material inlet 2 is opened above the frame 1, and the Below the material inlet 2 is a semi-cylindrical and hollow out discharge cage 7, in which a plurality of rotary hammer assemblies 3 are coaxially arranged, and adjacent rotary hammer assemblies 3 pass through The main shaft 81 is connected in series, one end of the main shaft 81 is connected to one side of the frame 1 through a bearing, and the other end is connected to the frame 1 through the power receiving axial assembly 4;

[0031] An impact plate assembly 5 is provided on the side above the rotary hammer assembly 3 that is staggered from the material inlet 2, and the impact plate assembly 5 can rebound the materials that are knocked up by the rotary hammer assembly 3 at different angles when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com