Sample pull stress corrosion tester

A corrosion test and tensile stress technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as bulky, affect the experimental effect, and have no conclusive standards, so as to achieve accurate detection data and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

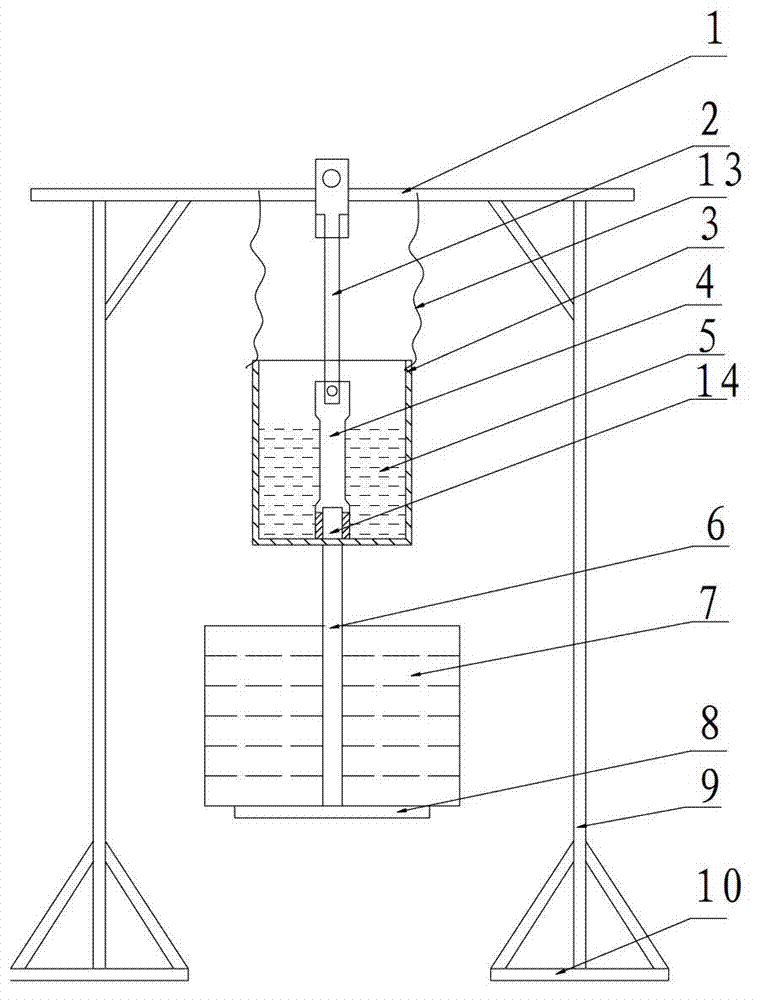

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

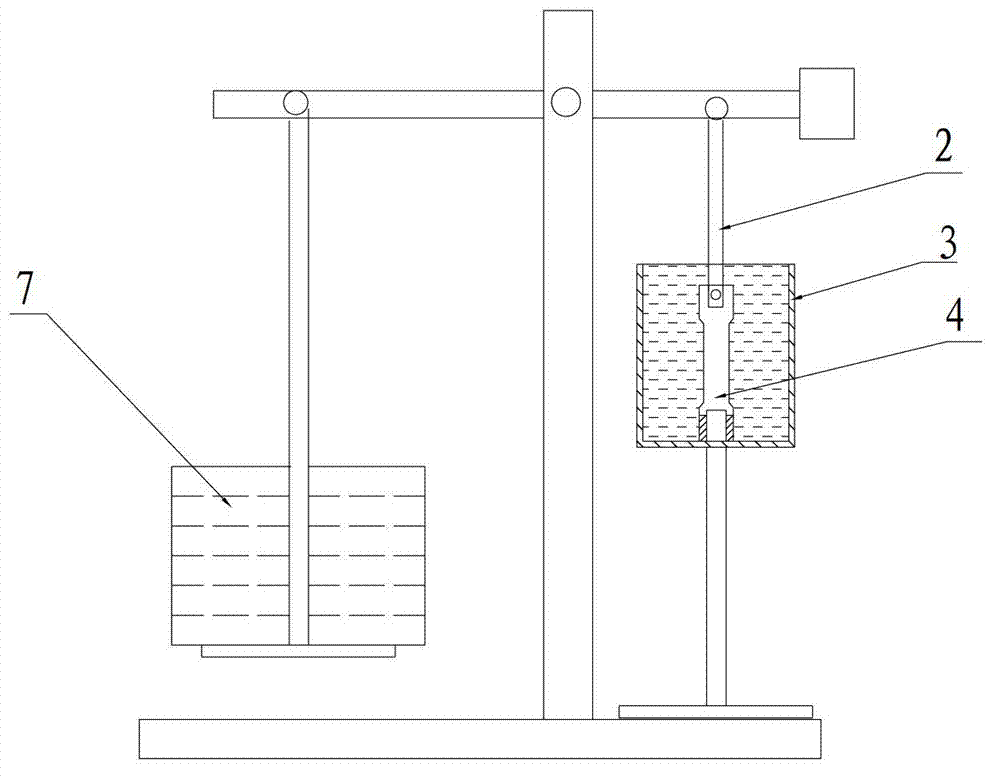

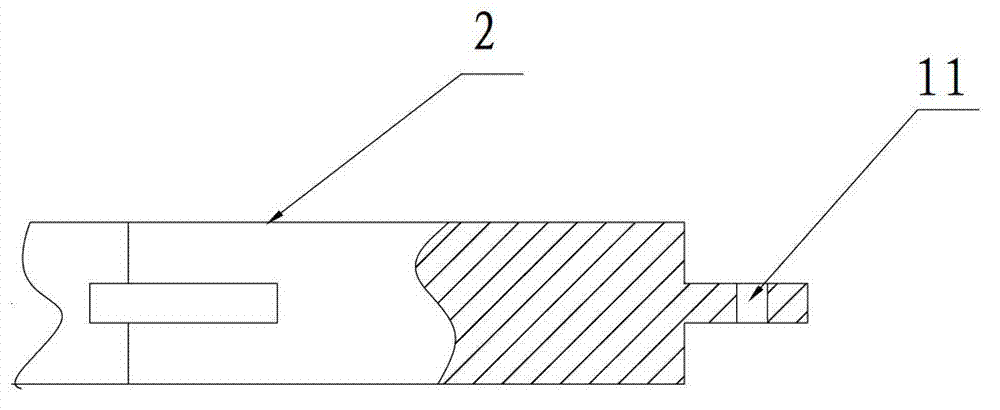

[0021] Such as Figure 2-4 As shown, a sample tensile stress corrosion testing machine includes a bracket, a corrosion cup, weights, an upper draw bar and a lower draw bar, and it is characterized in that the support includes a beam, and the upper end of the upper draw bar is connected to the The beam is connected, the lower end is connected with the sample, the upper end of the lower drawbar is fixedly connected with the bottom end of the corrosion cup, the lower end is provided with a weight seat, the weight code is placed on the weight seat, and the corrosion The bottom of the cup is equipped with a sample holding device.

[0022] The upper part of the corrosion cup is also provided with a safety rope fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com