Vacuum fireplace capable of effectively solving backfire problem

A problem, real fire technology, applied in the field of real fire fireplaces, can solve the problems of heat loss, fire, safety hazards, etc., and achieve the effects of increasing sealing, preventing burns, and increasing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

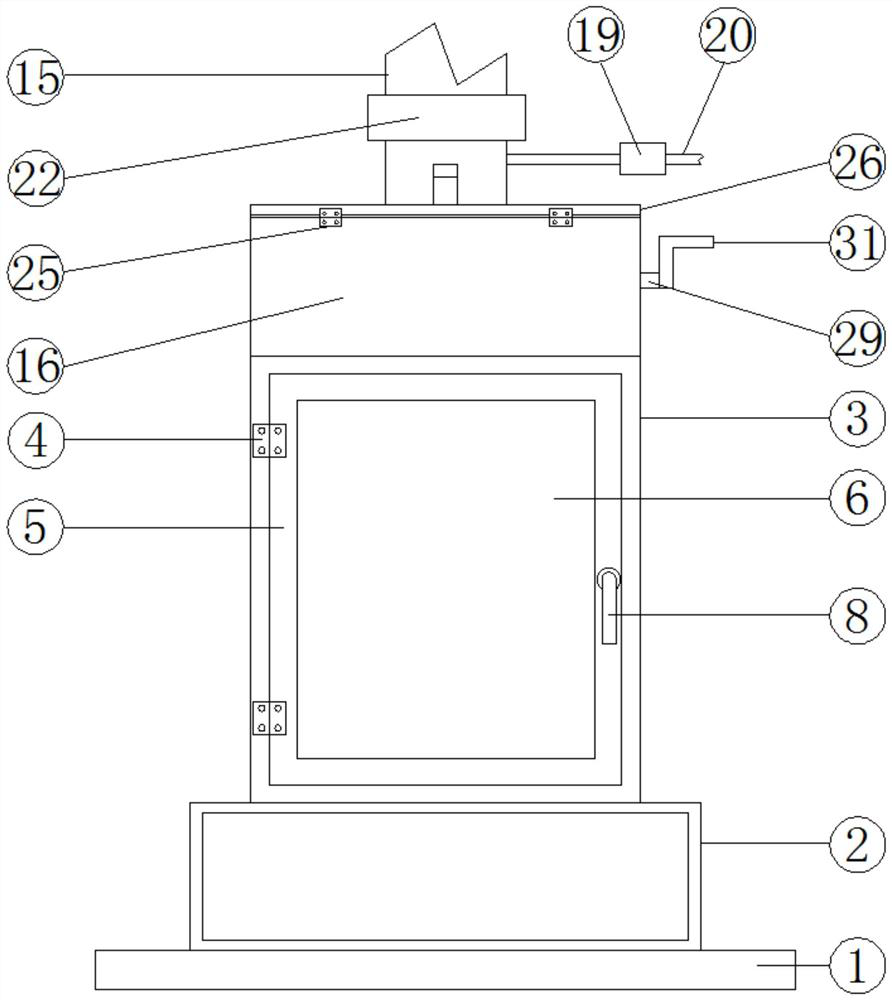

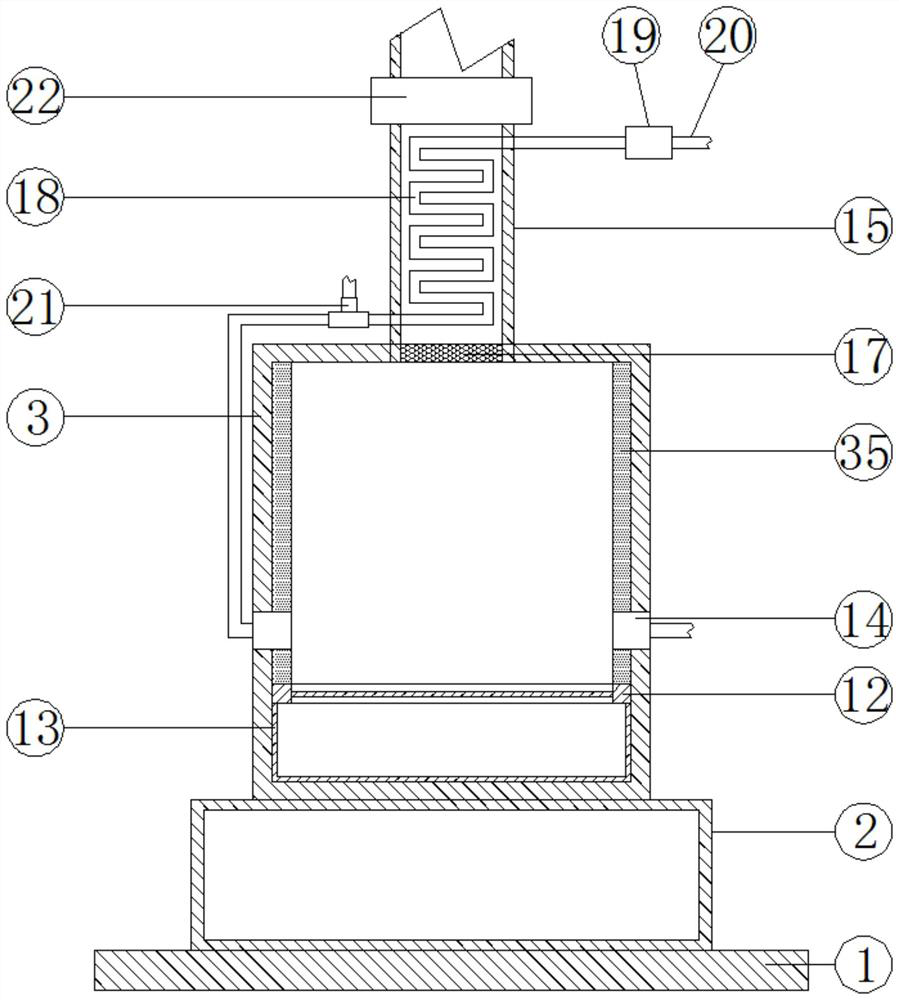

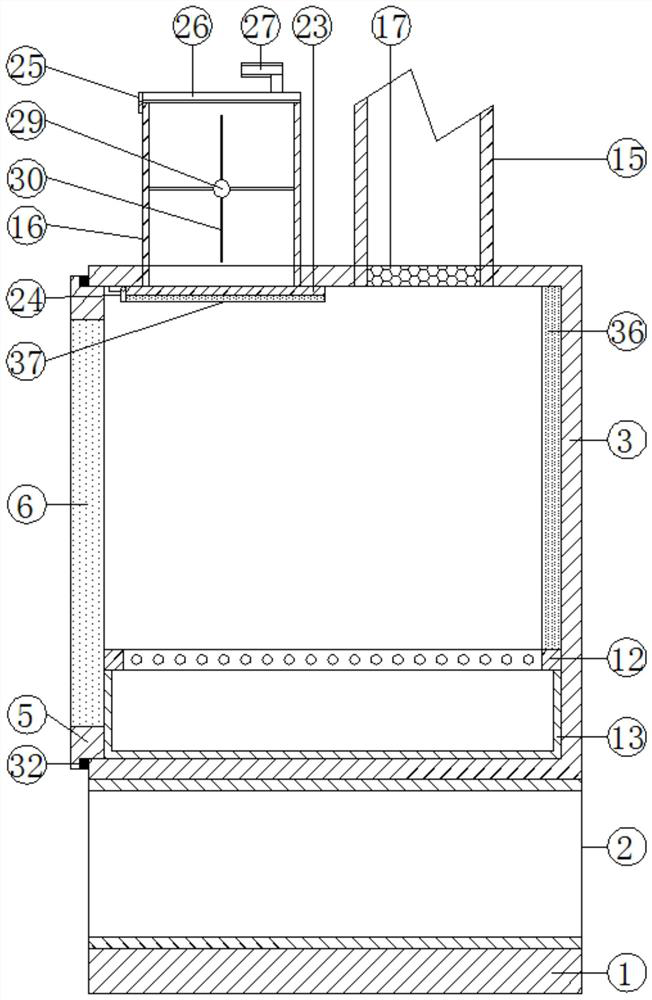

[0039] see Figure 1-9According to an embodiment of the present invention, a real fire fireplace that can effectively solve the tempering problem includes a base 1, a storage frame 2 is fixed on the base 1, and a furnace body 3 is fixed on the storage frame 2 The front of the furnace body 3 is provided with a door panel 5 movable through the first hinge 4, the middle part of the door panel 5 is fixedly embedded with a high temperature resistant glass plate 6, and the side of the door panel 5 away from the first hinge 4 is provided with a A locking device, the locking device includes a rotating shaft 7, the rotating shaft 7 is rotatably embedded in the side of the door panel 5 away from the first hinge 4, and the outer end of the rotating shaft 7 is fixed with a first handle 8 , the outer wall of the inner end of the rotating shaft 7 is fixedly provided with a block 9, and the outer wall of the rotating shaft 7 is fixedly provided with a limit ring 10 near the outer wall of bot...

Embodiment 2

[0042] see figure 1 and 5 , for the storage frame 2, the storage frame 2 is a box structure with two ends open and the storage frame 2 is made of heat-conducting material; for the base 1, the base 1 is made of heat-insulating material Made; for the second handle 27 and the first handle 8, the outer walls of the second handle 27 and the first handle 8 are fixedly covered with anti-scalding silicone sleeves.

[0043] Through the above scheme of the present invention, the material storage frame 2 is made of heat-conducting material, which can help the firewood in the material storage frame 2 to be preheated by the heat of the furnace body 3, and the anti-scalding silicone sleeve can protect the second handle 27 and the first handle 8 outer walls are insulated to prevent the second handle 27 and the first handle 8 from being overheated and scalding.

Embodiment 3

[0045] see image 3 , 7 And 8, for the door panel 5, the cross section of the door panel 5 is a convex structure and the inner wall of the door panel 5 is fixed with a sealing gasket 32, and the sealing gasket 32 is made of a high temperature resistant material; In other words, the setter 12 includes a frame body 33, and a plurality of connecting rods 34 are fixed at equal intervals between the inner walls of the frames on both sides of the frame body 33.

[0046] Through the above scheme of the present invention, the sealing gasket 32 can increase the sealing between the door panel 5 and the furnace body 3, the frame body 33 and the connecting rod 34 can be used to carry firewood, and the ash generated by combustion can fall to the ash collection below. Inside box 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com