Method and apparatus for conveying material from a combustion boiler

A technology for burning fuel and boilers, applied in the field of material devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

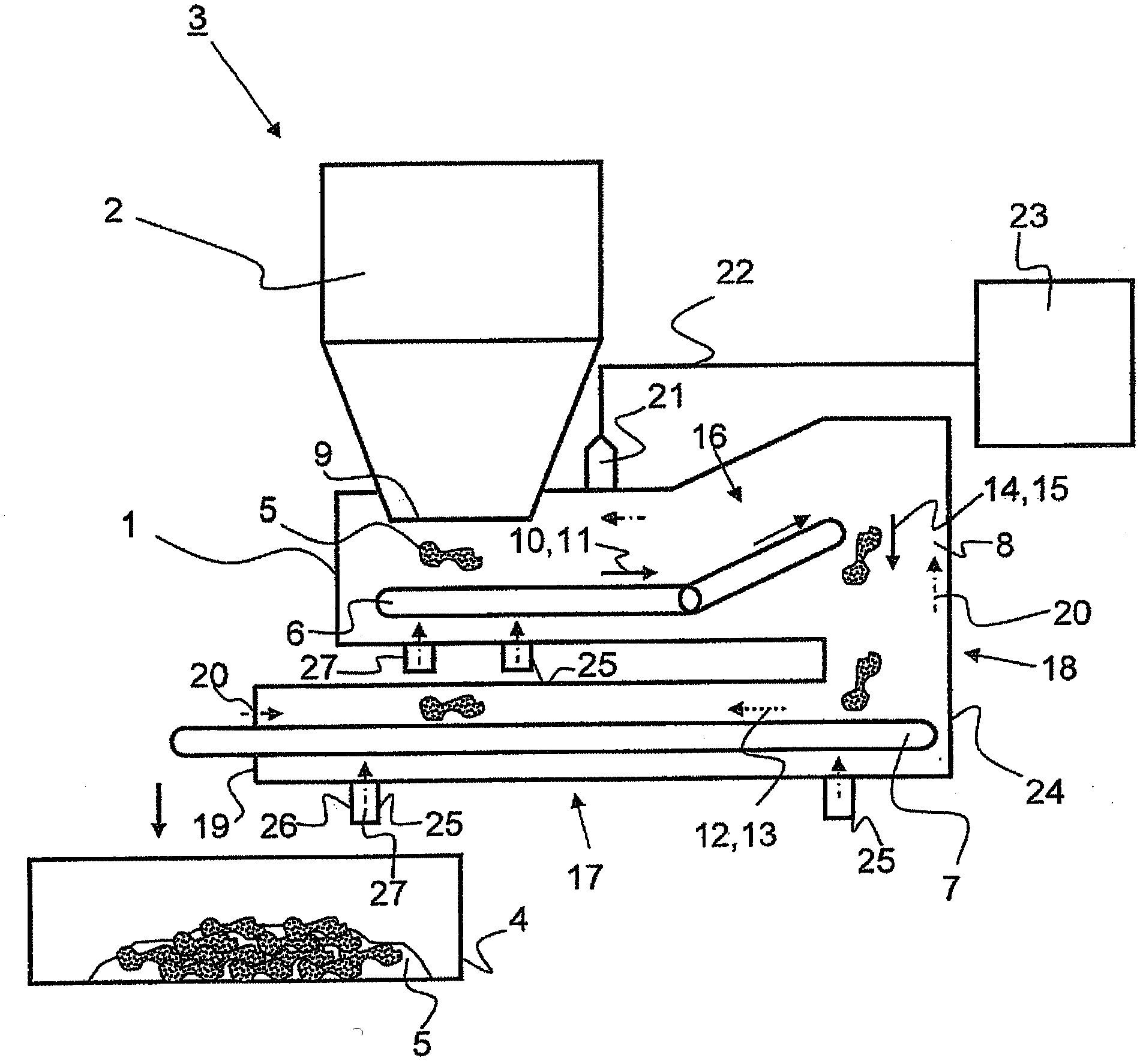

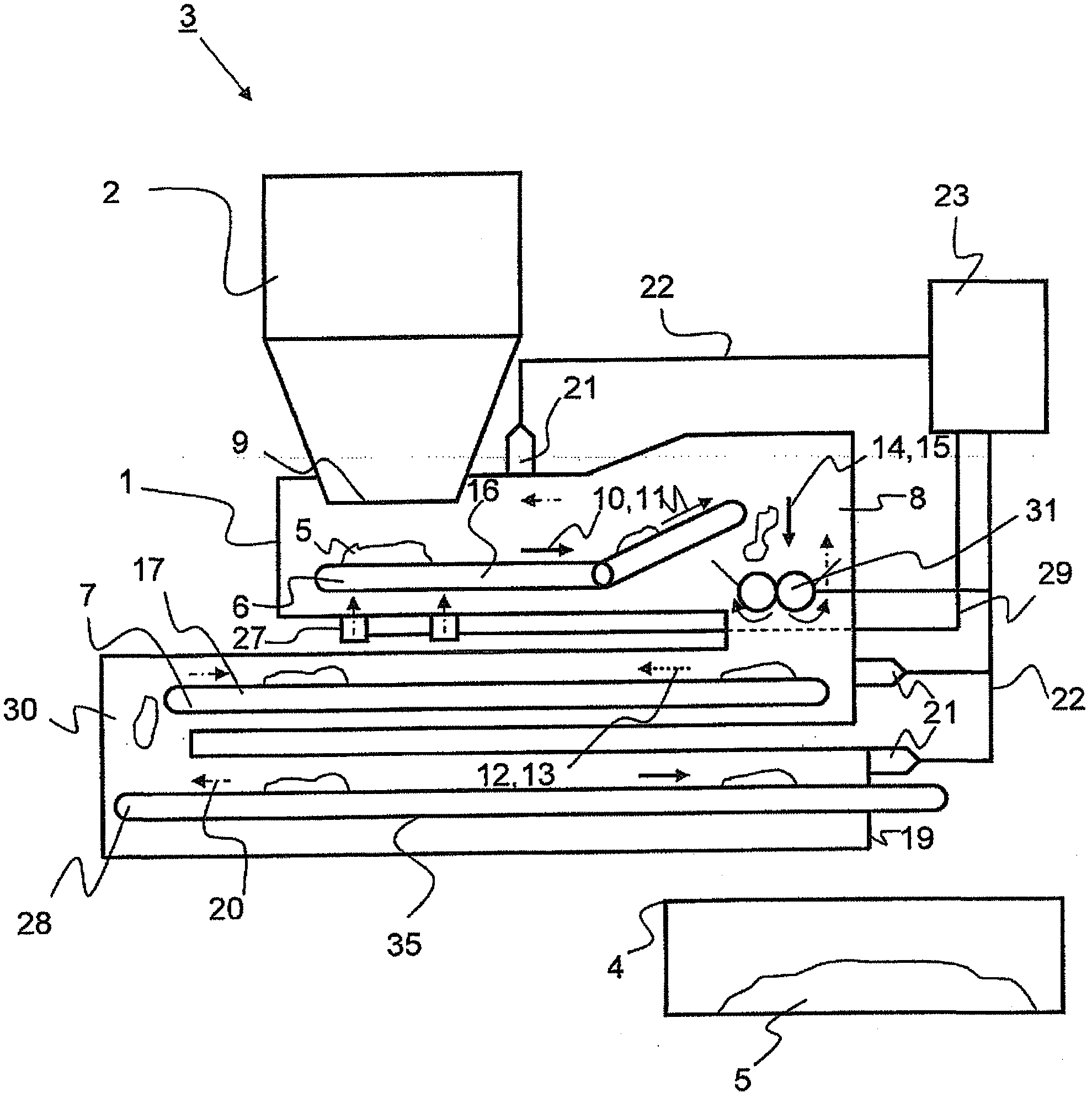

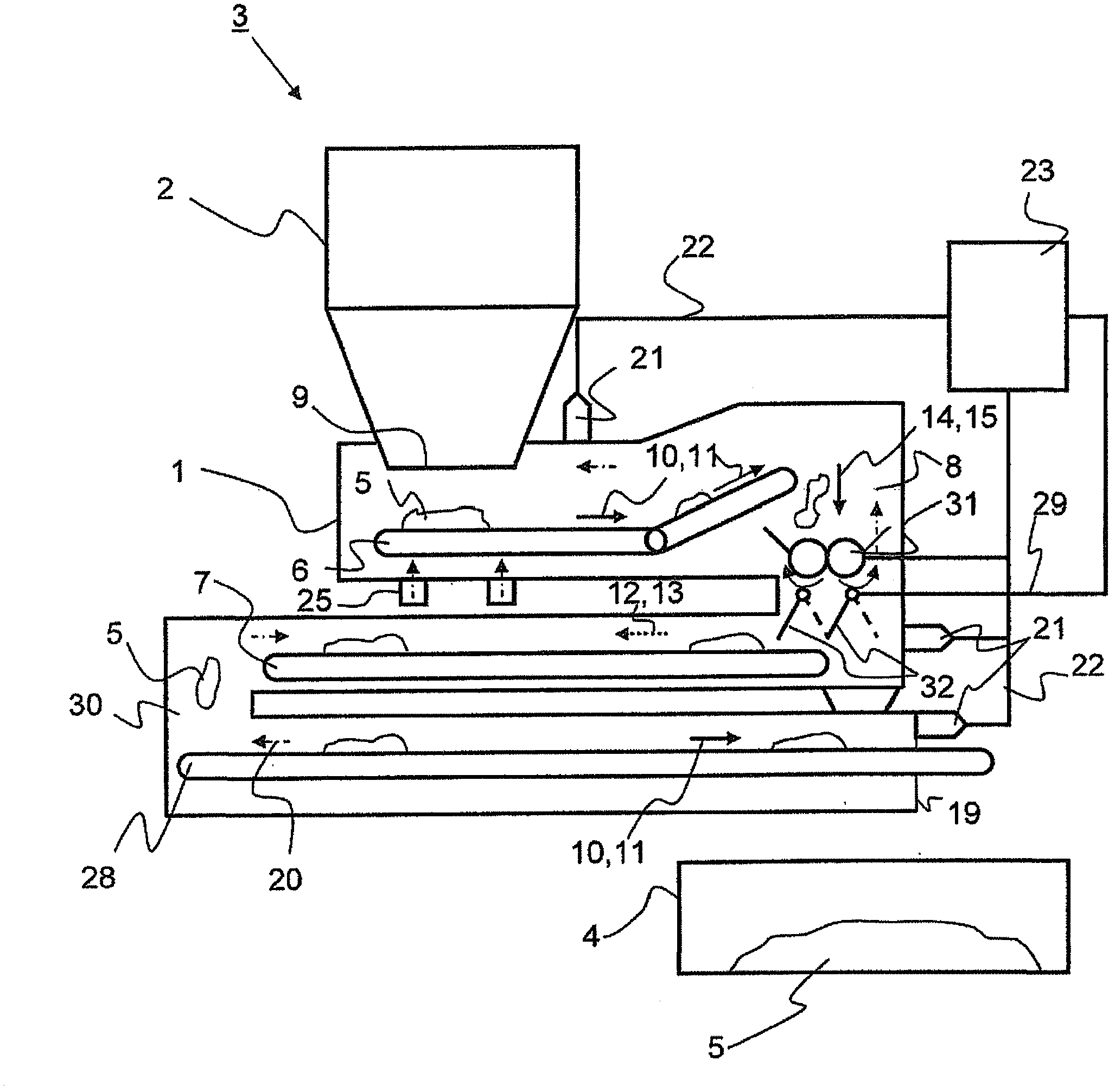

[0037] exist figure 1 A schematic side view of a first preferred embodiment of the device 1 according to the invention is shown in . The device 1 is arranged below a combustion boiler 2 in which fuel, for example refuse and / or fossil fuels such as coal, is combusted. The device 1 together with the combustion boiler 2 forms a plant 3 which is suitable for initially burning fuel and then transporting it away, and depositing the resulting material 5 in a container 4 . exist figure 1 The device 1 shown in is composed of a first conveyor belt 6 and a second conveyor belt 7 as well as a diverting device 8 . The material 5 discharged on the bottom side of the combustion boiler 2 (on the bottom mouth) passes through the outlet 9 onto the first conveyor belt 6 . From there, the material is guided by the first conveyor belt 6 in the direction of the first arrow 10 in the direction of the deflection device 8 . In the device 1 shown, the deflection device 8 is formed particularly simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com